Table saws have many problems. Among them, smoking is one of them. When we are working we can see, a table saw can be smoking due to main 10 reasons. If you are not a professional woodworker, you will not identify the correct reason and solution. So let me explain to you Why is your table saw smoking.

Table saw is smoking due to reasons such as motor overheating, capacitor burning, sawdust burning, using a dull blade, misangle blade, wrong blade height, dirty blade, bent blade, inclined workpiece, and incorrect feeding rate. These can be fixed by using a proper blade with correct cutting methods.

These reasons can be categorized mainly into two. Electrical smoking and wood smoking are them. You can identify the smoking by seeing the smoke color and bad smell. So let’s see, what are the reasons for table saw smoking all in detail.

1. Table Saw Motor Overheating

When we are working using a table saw for a long time, its motor can be heated due to friction and electricity. The armature is rotating inside the motor, and brushes are touching the commutator. When the brush touches the commutator, it can be heated. When the electricity and coils are heated too much, their melting parts can be melted due to heat, and the smoke can rise up.

When there is a problem with the bearing, it can be heated due to friction. When the bearings are heated, they can spread all over the motor. So check the bearing and keep the dust-free motor.

The solution for the table saw overheating is to stop the table saw and let it cool. You should not use a table saw continuously.

2. Table Saw Capacitor Burning

Due to the heat up, capacitors are unable to store the electrical charge. Overheating causes high internal gas pressure inside the capacitor case. When the capacitor is burning, you can feel the electrical smell. When the capacitor is burning, we can observe motor is not starting, is overheating, and is vibrating the motor.

The solution for the table saw capacitor burning is providing enough air space around the capacitor as it can cool the surface of the capacitor.

3. Table Saw Dust Burning

Sawdust is the debris of the wood. When the sawdust is entered into the motor, it can burn due to motor rotation. When the sawdust enters the brush area, it can dry grinding and as a result, smoke can rise. When the lignin is melted due to heat, sawdust can adhere more and more. When the motor is heated up, lignin can be melting, and sawdust can be burned due to motor rotation.

The solution for the table saw dust burning is cleaning the motor free from dust.

4. Table Saw Blade is Dull

The dull blade is not sharp as it needs to cut the wood. When the blade is dull, it is unable to remove the chip by cutting it sharply. It tends to scratch the wood with high RPM. As a result of this, wood tends to burn due to friction. You can observe scratch mark on the cutting surface.

The solution for the dull table saw blade is to use a brand new saw blade or resharpen the saw blade properly.

A table saw can be dull when it is hit with a harder material such as nails in the work piece. You can neglect it and can cut through the nails using a table saw blade by using a carbide-tipped saw blade.

5. Table Saw Blade is Inclined

When we cut the wood, we should maintain the proper angle. We have to feed the workpiece right along the saw blade rotating path. When the blade angle is inclined, and when we push the workpiece towards the blade, it will scratch with the blade, and heat will go up due to blade rotation. As a result of this, it will burn, and smoke will rise.

The solution for the inclined table saw blade is maintaining the proper saw blade angle according the cutting requirements

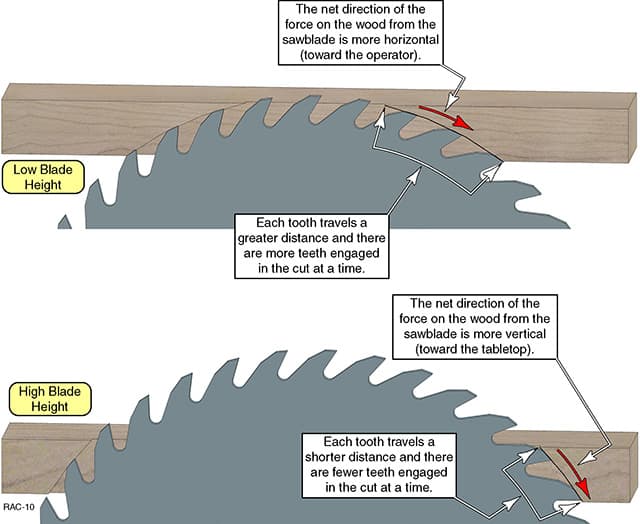

6. Table Saw Blade Height is Not Sufficient

When the blade height is too low, teeth friction can be high. As a result of this, you can see some splinterings from the top surface. Due to high friction, you can see some burning marks, and sometimes smoking can rise.

The solution for the insufficient table saw blade height is maintaining the proper blade height according to the user, tool and workpiece.

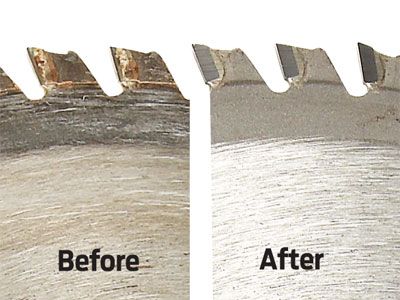

7. Table Saw Blade is Dirty

When the saw blade is used continuously, sawdust can be collected on the blade surface. Sometimes lignin melting also increases this. Some the thickness of the blade can be increased due to this sawdust. When we use this kind of saw blade we can observe additional abrasion due to this. As a result, the surface can be heated up, and then smoking can rise easily. So keep the blade clean if it is dirty.

The solution for the dirty table saw blade is cleaning the table saw blade with using a suitable cleaner. You should use a cleaner that dissolves rust and lignin on the saw blade.

8. Workpiece is Inclined with a Table Saw

When the workpiece is inclined and it is out from the sawing line, it can be smoke due to the hard scratching blade and wood surface. Normally, the workpiece should be lined up with the cutting blade and cutting path. When we push the inclined blade surface, touch the workpiece. So, heat up, and smoke rises.

When correcting the cutting line this can be seen. And surface burn of the wood can be seen.

The solution for the table saw workpiece inclination is to align the workpiece properly with the table saw guide rail

9. Table Saw has an Incorrect Cutting Speed

The cutting speed of the wood piece should be compatible with the RPM. If the RPM is high, we can feed the material high rate. If the feed rate is law and RPM is high, it will contact the surface much time, and as a result of it,, we can see burn marks on the surface with smoking the table saw.

The solution for the table saw incorrect cutting speed is maintaining the proper RPM and Feeding rate (SFM)

How to Prevent Table Saw Smoking?

You can prevent table saw smoking by following the below steps.

- Regularly clean the table saw.

- Sharpen the saw blade frequently.

- Use the correct type of blade for the material you are cutting.

- Adjust the saw blade to the correct height.

- Reduce the pressure applied when cutting.

- Do not cut wet or damp wood.

- Let the saw blade cool down periodically during heavy use.

- Ensure that the blade is properly aligned.