When we use a table saw, safety is more important. Because so many amputations occur due to poor safety instruments. Push sticks are the most important safety tool that we can use in table saw operations. There are kinds of push sticks and push blocks. These are different by their usage and shape. So let’s see all the details about push sticks.

Push sticks are safety tools which are used in table saws in order to push the workpiece forward without harming the hand. Using a push stick will prevent the kickback by turning the workpiece and any finger injuries.

We can divide push sticks into two categories such as conventional and modern. Conventional push sticks are completely made of wood, but modern push sticks are made with plastic and rubber in order to maximize traction. So let’s see all in detail about push sticks and their usage step by step.

What is a Push Stick?

A push stick is a safety tool that is used to push a piece of wood through a table saw or a router table. Push stick keeps the woodworker’s hands and fingers away from the saw blade. Push sticks are made of wood. It can be made easily with using a piece of wood. These are not safer than push blocks. But it can prevent finger injuries and amputation using a table saw. So you should use a push stick while you are using a table saw.

If you do not use a push stick, there is a risk of finger amputation. According to the NEISS, more than 30000 finger/ hand injuries occurred in 2018 due to the table saws.

What is a Push Block?

A push block is a safety device that is used in table saw. Push allows the worker to push a piece of wood through a table saw or router table without putting their hands near the blade or bit. It provides better control over the movement of the wood. It helps to produce a cleaner cut and significantly reduces the risk of injury. Push blocks can either be purchased or handmade and come in various shapes and sizes to accommodate different types of woodworking tasks.

What are the Differences Between Push Stick And Push Blocks?

Push sticks and push blocks are two types of pushing tools that we can use in sawing. Both are used for the same task. But there is a difference in shape, weight, material, etc. as for me bush block is safer than a push stick.

- Push sticks are lightweight, and push blocks are more weight.

- Push sticks are made of wood, and push blocks are made of plastic.

- Push sticks are easier to handle than push blocks

- Push sticks have more traction than push blocks

- Push sticks push with a single point or line, while push blocks have a rubber foot.

What are the Types of Push Sticks and Push Blocks?

According to the usage and manufacturing, we can categorize push sticks into two categories. Those are conventional and modern. Those can be used for specific tasks and operations.

- Double-handled hold-down push block

- Frontal Push Block

- Side Push Block

- Simple push stick

- Modern Push stick

How to Use a Push Stick?

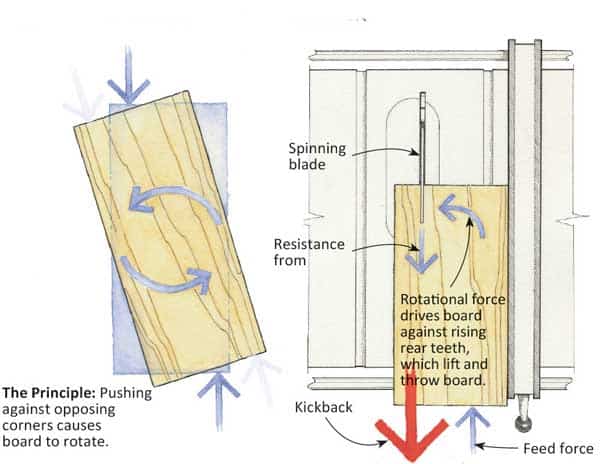

When we use a push stick, we must use it in a proper way because wrong pushing can hurt your body parts. When we push the workpiece to the blade, we must push it without having any rotational force. If we use a conventional push stick, we can observe this because it has a single edge. if we do not push with the center, it can generate rotational force. So we can observe kickbacks.

But when you use a push block or wider push stick, you can’t see this because push blocks strongly traction with the surface and that will not tend to rotate. So, there is no rotational force, and we can feed the workpiece to the saw blade easily.

When we use the push stick, we should not use the push stick and our handle more than the length of the hand. Because we have to force the workpiece so it can rotate easily, if the user and blade length is more than the hand and stick, use a push block. If a single push block is not enough, use a couple of push blocks.

Be careful when you use plastic or wood push sticks. Those have less friction, and they can slip on the surface when you push more.

Plastic push blocks can be used above the saw blade with its mechanism. So it is a great solution for kickbacks and many injuries. You can change the cutting width of the push block. Sometimes you can edge sides of the push blocks. So it will not move here and there.

What are the Negative Impacts of Push Sticks?

Although push sticks protect the fingers, it has some negative impacts due to its usage, price, materials, and user experience.

These are the negative impacts of push sticks.

- Reduced the workpiece control – Using a push stick can sometimes reduce the feeling of control over the wood piece you are cutting.

- Reduce the accuracy of the cut – Using a push stick can reduce the precision and accuracy of the cut.

- Increase the accidents when push stick used wrongly – If the push stick isn’t used properly, it can lead to accidents as a result of slipping or twisting.

- Push sticks are not suitable for all sizes – Push sticks aren’t suitable for all sizes of wood, particularly very small pieces, which increases the risk of an accident.

- Push blocks are expensive – Purchasing a good quality push stick can add to the expenses of setting up a woodworking shop.

- Time consumption – Setting up and using a push stick can consume more time.

Do I need to Use a Push Stick for All Table Saws?

Yes, You should use push sticks for all types of table saws. It helps to ensure your safety by keeping your hands and fingers away from the blade while you are cutting wood. Even experienced woodworkers use push sticks because it only takes one moment of distraction or one slip for a serious accident to happen.