Circular saw smoking is mainly two types as wood burning smell and a chemical smell. The Circular saw wood burning smell rise due to problems with the circular saw blade and workpiece. The chemical smell rises in the circular saw due to overheating inside the circular saw.

Circular saw smoking can occur due to an overworked motor, dull saw blade, too much friction in the workpiece, too hard workpiece, improper lubrication of the tool, clogged vents in the tool, old or worn carbon brushes, incorrect sawblade installation, using wrong circular saw blade and lack of regular maintenance on the circular saw.

In order to prevent the circular saw from smoking you should regularly check and maintain the motor, choose the right circular saw blade, make sure the saw blade is sharp, keep the saw blade clean, avoid overworking the circular saw, lubricate the moving parts in the tool, replace the damaged parts in the circular saw, allow the tool to cool down while using, and always use the circular saw in correct position and speed.

What is Circular Saw Smoking?

Circular saw smoking is a situation where the smoking is emitted when it is starting and operating. Circular saw smoke is white in color, and in some cases, it can be black. Circular saw smoking can be coming from the wood as well as from the circular saw motor. Wood circular saw smoking is the smell of wood burning, while circular saw motor smell is similar to plastic burning.

Circular saw produce a wood smell when it is cutting the wood. When the circular saw blade sides are hardly in touch with the wood piece, it will produce more heat. As a result of this, we can smell wood burning from the circular saw.

Circular saws produce a chemical smell when there is a problem inside the motor. When the circular saw is overheated inside, rubber and plastic parts can be melted. As a result of this, we can feel a plastic burning smell from the circular saw.

What are the Causes of Circular Saw Smoking?

1. Dull Circular Saw Blade

When a circular saw is used for a long time, it can be dull easily. You can identify the dull blade by its cutting speed and binding.

Due to the blunt saw teeth, the material will scratch instead of cutting it. Hence it will generate more heat due to friction. As a result of this, smoking can rise and the cutting path is not straight.

If a saw blade cutting speed has been reduced considering its brand-new condition, it can be dull. And also, when the saw blade is binding to the workpiece is another sign of a dull blade. And also, you can see chips are not removed properly. This is very important. A brand-new saw blade will remove the chips, and when the blade is dull, the chips will turn to smaller sizes (dust).

If the saw blade is dull, you should sharpen it using a proper method. Carbide tip saw blades are not dull easily. Those can be used without sharpening for a long time. But due to some unexpected reasons such as cutting nails inside the wood will damage the teeth head easily.

You can prevent this by sharpening it easily by hand or using a sharpening service. Using a high-quality saw blade will minimize the sharpening and avoid smoking and burning the workpiece.

2. Wobble Circular Saw Blade

When you rotate the saw blade by hand, you can see the inclined saw blade positions. When you switch on the circular saw, you can see a wider saw blade than its regular thickness. In order to confirm the saw blade wobble, you can check the distance between teeth and shoe end in two points. If there are different distances, there is a saw blade wobble.

A wobble saw blade can cut wider kerf due to its abnormal spinning path. As a result of wobble, the workpiece surface can touch the saw blade while it is spinning. Due to the hard touching surface, its heat can go up, and we can observe smoking from the workpiece. Additionally, we can see burn marks on the workpiece on the cutting surface.

A circular saw can wobble due to the nonflat flanges, damaged arbors, bent saw blades, etc.

In order to prevent the circular saw blade from wobbling, you should replace it.

3. Misaligned Circular Saw Blade

The regular saw blade should be perpendicular to the arbor shaft. If the circular blade is not perpendicular, we can consider it as a misaligned saw blade. The circular saw blade should be tight with the proper flat flanges, washers, and nuts. If the sawdust is clogged between the flanges and saw blade, it will be misaligned easily.

When the saw blade is misaligned, it can wobble the saw blade. Due to the misalignment saw blade surface can touch the cutting surface tightly. As a result, the workpiece cutting surface can overheat due to friction.

In order to prevent this you should align the saw blade perpendicular to the arbor shaft well.

4. Dirty Circular Saw Blade

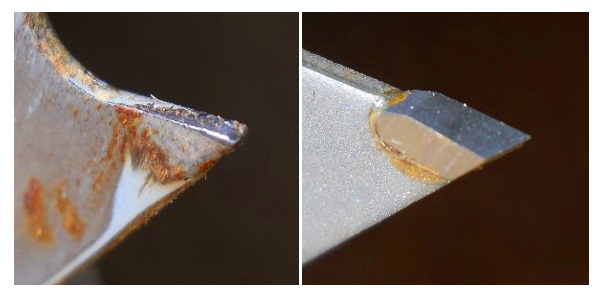

When we use a saw blade long period, dust can toughly adhere to the saw blade surface. This will make the surface rough. Sometimes it can increase the blade thickness due to the adhered sawdust. Not only dust but also rust can cause this problem also.

When the saw blade rotates, surface dust can also touch the cutting surface. As a result, surface friction will increase, and heat will be generated. Hence, we can see smoking and burning marks on the cutting surface.

In order to prevent this you can use blade cleaner to clean the saw blade. It is better if you can clean the saw blade regularly. It will reduce all problems easily.

5. Circular Saw Blade has a Higher Cutting Depth

Another factor for circular saw smoking is higher circular saw cutting depth. Normally, circular saws can cut 2 9/16 inch cut capacity effectively. If the workpiece depth is increased, the saw blade needs to spend more time in the workpiece.

As a result of this saw blade, surfaces will touch with the cutting surface much time. Due to the friction, it will heat up, and then we can see smoking there.

For the most efficient cutting action, set the depth adjustment so that one-half tooth of the blade will project below the material to be cut. This distance is from the tip of the tooth to the bottom of the gullet in front of it. This keeps blade friction at a minimum, removes sawdust from the cut, results in cooler, faster sawing, and reduces the chance of kickback.

In order to prevent this you can use a thin workpiece for cutting a circular saw. For the thicker workpiece, you can use a table saw.

6. Circular Saw is Using in the Wrong Supporting

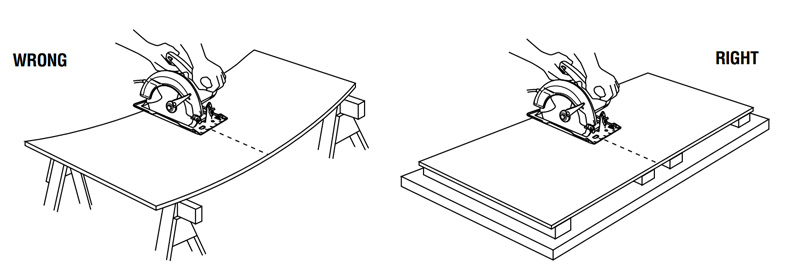

When we use a circular saw, we should have proper clamps and support in order to have an efficient and effective cutting process. When we use a circular saw, we should know how to place supports when we cut.

During the cutting process, the cutting surface should not be bending with the saw blade cutting path. During the cutting process, if the workpiece tends to bend from the cutting path, it will clog due to compression of the workpiece. Hence, heating can be generated.

As a result of this, we can see smoking. Sometimes workpieces can kick back due to improper support.

To prevent this, you should always keep the proper workpiece supporting as compression is not built towards the saw blade.

7. Insufficient Saw Teeth in Circular Saw Blade

Let’s see, how do saw teeth affect the cutting process?. We can cut rip cut, cross cut, and bevel cut using the circular saw.

A rip cut is done along the grain path. Along the grain, the path is not strong much. During the cutting process, more chips will be removed easily. As a result of this, we should use a lower number of teeth. If we use a higher number of teeth saw blades for rip cut, chips will clog inside due to less space of gullets. When it clogs inside, it will increase the inner friction. As a result of the friction, heat will rise and we can see smoking.

In order to prevent problems due to insufficient saw blade teeth, you should use the below number of teeth for each cut.

- General Purpose of cutting – 18 Teeth

- Smooth wood cutting – 24-60 Teeth

- Non carbide, plywood, vinyl siding cutting – 90 Teeth

8. Use a Circular Saw on a Lower Cutting Speed with a High RPM

When the saw blade is spinning, we should move the shoe forward on the workpiece. As I explained above, smoking occurs due to the friction between the saw blade and the workpiece cutting surface. When you reduce the tool feeding speed, the saw blade can engage more time with the cutting surface and blade. As a result of this heat can be generated. Finally, we can see smoking due to the heating of the woodworkpiece.

In order to prevent this, you should use the cutting and feeding speeds of the circular saw according to the workpiece material. If you use hardwood, you can use a lower cutting speed with hight RPM. For the soft wood, you can use lower RPM with lower cutting speed.

9. Circular Saw Blade is Warping

When the saw blade is bent or twisted due to any external force, we can see smoke from the workpiece. When the saw blade is bent or twisted, it can tightly touch the cutting surface. As a result of this, we can see burning and smoking on the workpiece.

In order to prevent this, you should replace the circular saw blade.

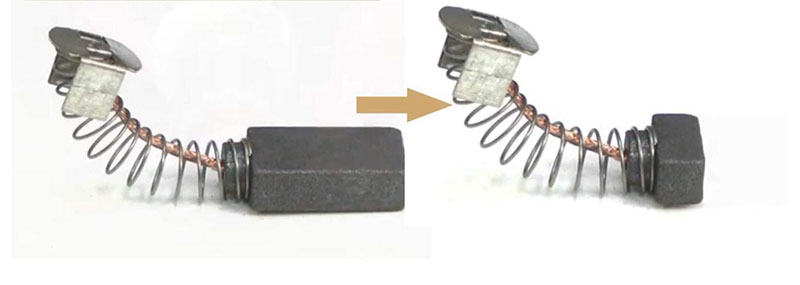

10. Motor Brushes Are Worn

If you feel the smoking smell is chemical, there is no doubt check the motor. Normally, most saw motors are brushed. The brushes are touch the commutator in order to supply the current and voltage. brushes are made with carbon; when the armature is rotating, brushes can worn due to friction. When the brushes are worn, we can see smoke from the motor.

In order to prevent this you should replace the brushes when their length reaches 1/4 of their initial length.