Miter saw sparking is one of the common problems for old miter saws. When the miter saw is used, its parts can cause abrasion due to friction. Due to this reason, we can observe many problems. When a miter saw is sparking, we can see many reasons.

Miter saw is sparking due to wearing carbon brushes, shorting out armature, worn bearing, broken brush caps, and shorting out the fields. Some miter saws normally spark when they are used. But it is not heavy sparking. If there is heavy sparking, you can see heavy light from the brush end.

After identifying the reason, we can fix it quickly. If there is a tool warranty, it is better to claim the warranty. Otherwise, you can follow the steps below and achieve the solution.

What is Miter Saw Sparking?

The miter saw sparking is visualizing the spark from the miter saw motor while running the motor. Miter saw sparking are two types such as light sparking and heavy light sparking.

Light sparking is normal for some miter saws. It is not a problem. When the carbon brushes hardly touch with the armature, heat is increased, and as a result of this carbon, brushes are worn out. These parts can be visible as sparks

Heavy light sparking is the problem. It is more than light sparking. Normally, light sparking is not able to identify from outside. But heavy light sparking can be observed from outside easily. When you observe heavy light sparking from your miter saw motor, it is time to repair soon.

Normally, light sparking in a miter saw is not a problem. It can be visible outside. But heavy light sparking in the miter saw is a serious problem. You must fix all necessary parts of the miter saw as soon as possible.

What are the Reasons and Solutions for Miter Saw Sparking?

Miter saw sparking can occur due to the below reasons. If your miter saw has heavy sparking, check these parts properly.

1. Worn Carbon Brushes

Carbon brushes are the main reason for the miter saw sparking. Carbon brushes are made with hard carbon. It is an electric conductor. It can provide electrical power to the armature. When the armature is rotating, carbon brushes are in touch with the commutator. It is necessary to supply continuous power to the armature.

Due to the speed of rotation, surface heat rises, and sparks can be visible. Normally, some miter saws have light springs. This can not be visible from the outside. When the carbon brushes are worn out, it can be seen heavily.

Solutions

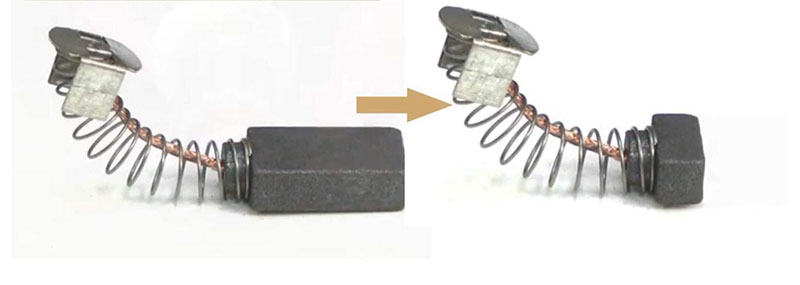

- Replace the carbon brushes when their length reaches 1/4 of their initial length.

- Check whether the brush springs are working well

2. Shorting Out Armature

The armature is the power-producing unit for the miter saw. It consists of coils. When the electricity is moving through the coil, motion can occur due to the magnetic field. The armature can rotate at high rpm. But some problems can occur to short the armature inside. The coil is wrapped with a thin rubber layer; when it is damaged, it can short inside.

This will be a heavy spark. You must fix this at the beginning. If you are late you will have so many problems.

Solutions

- Replace the armature

- Re-wrap the coils

3. Worn Bearing

One side of the armature shaft is fixed with a bearing. Bearings are not a lifelong part. It can be damaged due to misalignment, imbalance, looseness, friction, etc. If the bearing is damaged, you can see some sparking at the end of the armature shaft. This is more dangerous. The worn bearing will cause the miter saw blade wobble.

If you do not fix this on time, you have to replace the armature also.

Solutions

- Replace the bearings

- Add lubricants regularly

4. Damaged Brush Caps

When you use a miter saw, you may have observed brush caps. Brush caps are used to repair or replace the miter saw brush easily. Else you will need to remove more nuts and screws on the miter saw motor. It is hard work. So brush caps let you easily replace the carbon brushes in the motor.

By chance, if the brush caps are damaged, it will not tight well, and the inside brush will be misaligned. As a result of this, you can see sparks inside the motor.

Solutions

- Replace the brush caps

5. Shorting Out Field

The field is a copper coil. It has wrapped around the armature. The copper coil has been covered with a special rubber film. If the film is damaged, it can be short inside. This safety guide helps you to protect the motor windings.

Solutions

- Rewrapping the motor

- Avoid working in dust area

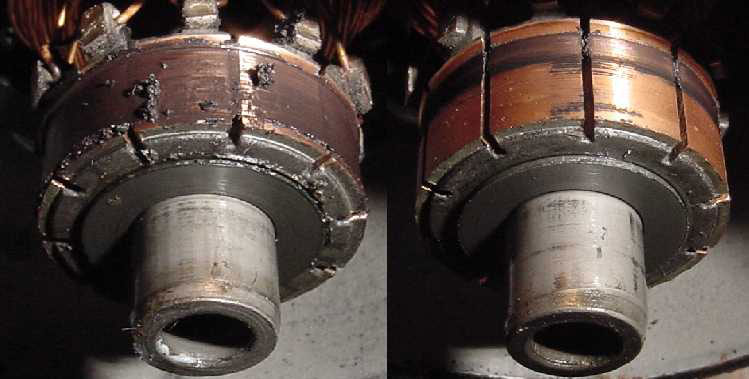

6. Dirty Commutator

The commutator can touch with the carbon brushes. When the commutator is used with dust, and oils it can be dirty due to some particles hardly touching the commutator surface. As a result of this, we can observe sparking on the brushes and commutator.

Solutions

- Clean the commutator

7. Miter Saw Sparking and Smoking

When we observe miter saw sparking in the miter saw motor, we can see or feel the smoke. If the smoke smell of wood. It can rise due to the workpiece. If the smoke is like a chemical smell, it can probably rise due to sparking.

Sometimes you may observe smoking due to oil burning. It is probably due to the inside lubricants heating due to inside heat generating. If you apply oil, grease during the repair or maintenance, you can see smoke from the motor. But this is not permanent. It is temporary smoke. Do not worry about it much. But make sure there is no heavy spark from the shaft end.

So smoking is not always due to the wood. It can be due to the sparking. You must apply proper lubricant and repairs on time in order to protect the motor mechanism.

How to prevent Miter Saw Sparking?

It is very important to know to prevent the motor saw from sparking. A miter saw can smoke due to the above reasons. But you can prevent or minimize all sparking problems by following these tips.

- Do not apply grease or oil too much – If you apply grease or oil too much, those can spread all over the motor. As a result of this, some dust particles can adhere to the inside surface. This will cause sparks easily.

- Do maintain and repair on time – The second most important thing is maintenance and repair of the miter saw regularly. When you repair, clean the commutator, apply the oil and grease to the necessary points, etc.

- Replace the brushes – You must replace carbon brushes when their length reaches 1/4 of their initial length.

- Fix the parts properly after every repair – Normally, parts should be fixed properly after every repair. If you fix the parts wrongly, as an example, unbalanced bearing will cause you to wear it. As a result of this, sparks can occur after a few times.