Miter saws are lightweight cutting tools. That can be used for woodworking, metalworking, etc. It is mostly used for high accuracy cross cuts, miter cuts, and bevel cuts. When we buy a miter saw, we can observe mainly 05 types of miter saws in the market. These are with different functions, pros, and cons. So let’s see what are the 05 best miter saw types and their pros, cons, usage, and other factors to be considered before you buy them.

Miter saw types can be classified into 05 with their main functions and usage.

| 5 Type of the Miter Saw | Main Functions |

| Regular/ Conventional miter saw | Crosscuts, 90°, and 45°cuts |

| Sliding miter saw | Crosscut, Miter cut, sliding |

| Compound miter saw | Crosscut, Miter cut, Single side bevel cut |

| Compound sliding miter saw | Crosscut, Single side bevel cut, Miter cut with sliding |

| Dual compound sliding miter saw | Dual bevel cut, Crosscut, miter cut, sliding |

Miter saws are classified according to their functions. So let’s see all these functions and their usage step by step.

01. Conventional Miter Saw

Conventional miter saw/Regular miter saw/Manual miter saw is the same-named miter saw in the industry. We can name this as the 1st version of the miter saw. The conventional miter saw has basic functions. At first, that was with the saw blade, and when the electricity was used rotational saw blade was used with an electric motor. You may have seen a chop saw. It is the basic miter saw using the saw blade. But conventional miter saw is with the saw blade. The earliest miter saw was composed of a backsaw in a miter box.

Early miter saws consist of wooden or plastic three-sided boxes with 90° and 45°. Later rotating saw blade is used instead of a conventional saw. It is mostly used to cut the 45° angle for both wood and metal basic cuts. The base sizes were 8¼” for the small miter saws.

The conventional miter saw is unable to pivot its blade in a vertical position. But it can pivot left or right position to cut the bevel. These kinds of miter saws can be seen in traditional woodworking. When the electric miter saw blade was introduced, this was used for both woodworking and metalworking.

Pros of conventional miter saws

- Conventional miter saws are easy to handle

- Conventional miter saws consume minimum space

- Conventional miter saws are easy of use for basic cutting tasks

- Conventional miter saws are suitable for beginners

- Conventional miter saws are portable and can be used on job sites

- Conventional miter saws can handle a variety of materials

- Conventional miter saws can quickly setup and operation

Cons of conventional miter saws

- Conventional miter saws has a manual sawing process

- Conventional miter saws has a limited cutting capacity

- Conventional miter saws are less precise than some advanced models

- Conventional miter saws not suitable for complex angle cuts

- Conventional miter saws produce more sawdust and debris

- Conventional miter saws need a manual adjustment required for angle and bevel cuts

02. Compound Miter Saw

The compound miter saw name is based on its function. Normally basic miter saw is used to cut limited angles. But this has extended a bit with using the compound miter saw. Miter saw angle should be calculated according to this guide.

If the cutting axis is tilted to a single direction, it is called a single compound miter saw. Using a single compound miter saw, you can cut both bevel and miter cuts easily. Compound miter has developed into the higher level for the miter and bevel cuts.

Compound miter saws are powered by an electric motor with a suitable cutting blade. Most cutting blades are 10 inches and 12 inches. When using a compound miter saw, you can cut easily both bevel and angle cutting together.

Due to the limited cutting capacity, thicker workpieces are not able to use. Compound miter saws are really useful.

Pros of compound miter saws

- Compound miter saws deliver precise cuts for complex angles and bevels.

- Compound miter saws are versatile, suitable for both straight and angled cuts.

- Compound miter saws save time as you can cut in two angles at once.

- Compound miter saws have adjustable blades to facilitate different cut styles.

- Compound miter saws often have dust collection systems, providing a cleaner working environment.

Cons of compound miter saws

- Compound miter saws are heavy and not easily portable.

- Compound miter saws can be more expensive than other saw options.

- Compound miter saws require regular maintenance to keep them in good working order.

- Compound miter saws can be difficult for beginners to use effectively.

- Compound miter saws can consume a large amount of electricity when used frequently.

03. Sliding Miter Saw

Sliding miter saw is another type of miter saw. It can cut deeper cut in wide range with considering the fixed miter saw. There is a rail that can move the blade and handle it horizontally. As a result, it can cut wider workpieces into deeper ones.

The cutting depth is 4-5 inches. If you use 12 inches saw blade, you can cut a little bit more than 5 inches. But not 6 inches height workpiece.

Normally sliding range is about 15 -12 inch kerf.

According to the rail fixing, we can see 3 different types of sliding saws

- Fixed Rails – The rail is fixed to the body, and the saw is moving along the rail.

- Moving Rails – The Rail is fixed with the saw and motor, and it slides on the body of the saw.

- Articulating Hinge – This is know as the axial glide saw. A hinge system is used instead of a sliding mechanism.

When you use fixed rails or moving rail sliding, saw you would need extra space for the rail movements. But articulating hinges will require the least space for the miter saw operations.

More than that, sliding miter saws are higher efficient than fixed miter saw. I can explain this like this.

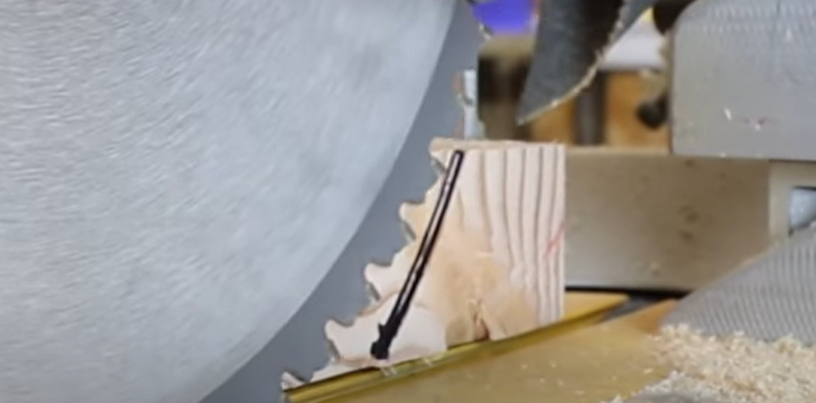

When a fixed miter saw cut the workpiece, many teeth need to contact the material. At this time, we can see some tearings burning marks.

But if you use a sliding miter saw, you can have a proper crosscut because we have to slide outside of the workpiece and then push the rotational blade to the workpiece. At this time, fewer cutting teeth are engaged with the cutting surface. As a result of this, we can expect a more efficient and clean cutting surface.

Pros of sliding miter saws

- Sliding miter saw offers extended cutting length for wider workpieces.

- Sliding miter saw enables precision cuts with its accurate laser guide.

- The sliding miter saw operates smoothly thanks to its advanced features and technology.

- Sliding miter saw allows for angled cuts with its adjustable miter and bevel settings.

- Sliding miter saw provides a safer work environment with its built-in dust collection system.

Cons of sliding miter saws

- Sliding miter saws can be more expensive than other types of saws.

- Sliding miter saw may require more maintenance due to its complex features.

- Sliding miter saw is heavier and bulkier, making it less portable.

- Sliding miter saw needs a larger space to operate efficiently.

- Sliding miter saw could possibly cause more kickback and be potentially dangerous for inexperienced users.

04. Compound Sliding Miter Saw

In the compound sliding miter saw can be used for the single side bevel cuts, miter cuts, cross cuts with sliding the saw head. The saw head is moving forward and backward using the rails, and it can pivot left or right side. Due to the sliding function, it can increase the size capacity of the workpiece. But there is a limited bevel option due to the single side.

If you use this, you will need to flip the workpiece in order to have the dual bevel option. Due to the sliding function, a larger size workpiece can be cut.

Mostly this tool is used for the 2″×12” or 1″×12” workpieces.

Pros of compound sliding miter saws

- Compound sliding miter saw provides precise cuts in various angles.

- Compound sliding miter saw allows for sliding action, useful for wider workpieces.

- Compound sliding miter saw can perform both miter and bevel cuts in one pass.

- Compound sliding miter saws often include an in-built laser guide, enhancing cutting accuracy.

- Compound sliding miter saw provides user-friendly adjustments for easy use.

Cons of compound sliding miter saws

- Compound sliding miter saws can be quite expensive compared to other types of saws.

- Compound sliding miter saw occupies more space due to its sliding feature.

- The compound sliding miter saw is relatively heavy, making it less portable.

- Compound sliding miter saw requires regular maintenance for optimal performance.

- Compound sliding miter saw may not be suitable for beginners due to its complexity.

Read More About – How Much Space Need for Miter Saw?

05. Dual Compound Sliding Miter Saw

Finally, a dual compound sliding miter saw is with combining all the functions together. It is the most used miter saw, and it has developed well in today’s tool market. Dual compound sliding miter saw can cut cross-cut, left or right bevel, miter cut, with sliding.

Due to the sliding mechanism, it can cut larger sizes of workpieces with any bevel angle. When you use this, you don’t need to flip the workpiece in order to left-right bevels. Using a bevel scale and angle, you can easily do this. Normally dual compound sliding miter saws are expensive. If you are looking for the budget miter, saw you can move to another.

You can use both 10 inch, and 12 inches blade sizes in this miter saw.

Pros of compound sliding miter saws

- Dual Compound sliding miter saw offers increased cutting capacity and accuracy.

- Dual Compound, sliding miter saw, allows for bevel cuts at any angle, providing added versatility.

- A dual Compound sliding miter saw is ideal for making precise cuts for crown molding and other intricate woodworking projects.

- Dual Compound sliding miter saw provides the convenience of portability, making it perfect for job site use.

- A dual Compound sliding miter saw ensures less waste and fewer mistakes as it requires less setup and maneuvering of the workpiece.

Cons of compound sliding miter saws

- Dual Compound sliding miter saw may be expensive compared to single bevel miter saws.

- Dual Compound sliding miter saw can be heavy and bulky, making it difficult to transport.

- Dual Compound sliding miter saw may have a steep learning curve for beginners.

- Dual Compound sliding miter requires regular maintenance for optimal performance and longevity.

- The complexity of the dual compound sliding miter saw means repair work can be more time-consuming and costly.

What are the Disadvantages of Miter Saws

These are the 8 disadvantages of miter saws

- Limited cutting capacity

- Difficulty in cutting larger materials

- Not suitable for rip cuts

- Power consumption is high

- Potential for inaccuracy

- Requires regular maintenance

- Blades may dull quickly

- Not ideal for detailed work