When you buy a drill, you can see there are two types of drills according to the motor mechanism. Those are categorized according to the brushes. So there are so many differences between these two mechanisms. So let’s see what are the differences between brushless vs. brushed drills. This guide will help you to select a perfect drilling machine.

Brushless vs. brushed drills are different. Brushless drills are always high efficiency, low noise, no spark, easy to maintain, high torque, compact size and high durability as well as 25% efficiency, 50% motor runtime, and 10X motor lifetime is higher than the brushed drill.

Brushless drills are steps away forward considering the brushed drills with their performances and many characteristics. You will need to add additional costs for the brushless drill rather than brushed drills. This is a detailed guide for buying the brushes drill and brushless drills in the market. Let’s keep reading on!

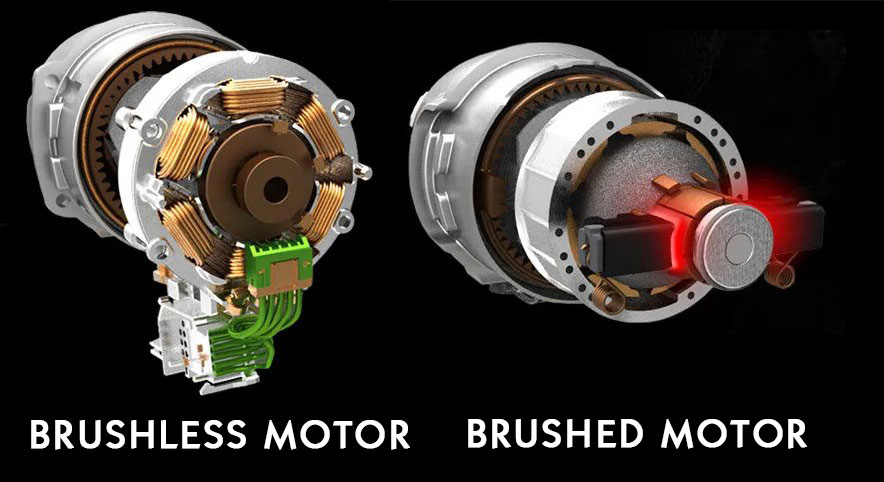

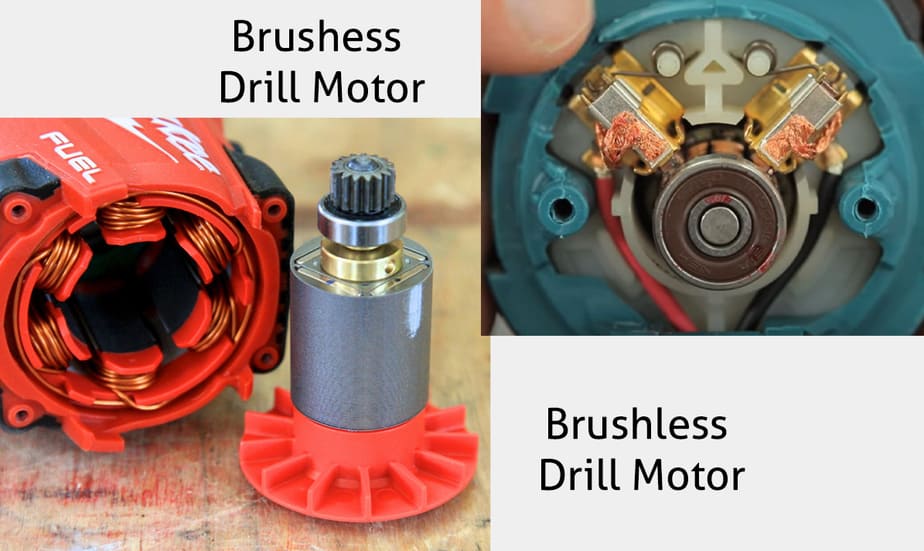

How Does a Brushed Drill Motor Work?

Brushed drills are used in verities fields and are widely used. Due to the low manufacturing cost, it can be used for fulfilling many rotational needs. This motor is with a simple mechanism with few parts. Brushes, commutator, armature, and magnets are the main parts.

The armature rotates by power up the commutator and brushes. Brushes always touch the commutator, and a constant current is flown through the commutator to the armature.

When a current is flown through the metallic wire, a magnetic field is produced. This magnetic field interacts with the external permanent magnets.

Due to this, pushes and attractions occur. When this rotation continuously happens, the armature spins its axis. A motor powers the drill. Drill performance depends on the performance of the motor.

This is the simple explanation of the brushed motors in the drills. But there are so many advantages and disadvantages. Both you should know before buying this. After knowing everything, you can have the best and the most efficient drill for your tasks.

How Does a Brushless Drill Motor Work?

Brushless drills use brushless motors to generate the power.

The brushless motors are DC and powered by batteries. Power is delivered to the electronic unit, then it optimizes power output to the stator, and its reason is an electromagnetic field.

This field drives a permanent magnet built around the rotor. Brushless drill motors are extremely worth their additional cost. Let’s see the advantages and

Advantages and Disadvantages of Brushed Drills

Advantages of Brushed Drills

- Cheap – Manufacturing cost is low. Therefore there are so many verities. These brushed motors are available everywhere. So many kinds of parts replacing repairing can be done easily. According to the quality and the mechanism, its cost depends.

- Easy to Maintain – When considering the brushed drill motor, it can be damaged due to any reason. These motors are very cheap, and parts are available everywhere. Because of this, it can be maintained at any time with the least technical knowledge. You can replace parts yourself.

- No need for Special Technical Knowledge – When you fix something, you will need special technical knowledge for it. But for the brush drill, motor repairs, and parts placing, you will no need special technical knowledge.

Disadvantages of Brushed Drills

- Less Efficient – Considering the brushed drill and brushless drill, there is a huge difference in efficiency. So let’s see how this happens. In the brushed motors, there is a copper pad that is a touch on the commutator and provides the current to the armature. When the armature is spin commutator also spins its axis. Therefore brushes touch the commutator and produce heat, spark, and noise. Because of this, energy is wastage. Therefore the motor acts inefficient manner with considering the same power brushless drill motor.

- Brushes Can be Damaged – The commutator and brushes are touches during the rotations to provide the current to the armature. Because of this, friction has occurred, and brushes can be subjected to abrasion. When the brushes are abrasion, it needs to be replaced every 50-60 hours of usage. This will add more cost considering the brushless drill motors.

- Noisy – When the brush and commutator scraping each other, there will be a noise due to the friction. As well as when you see carefully from the back of your drill, you can see some sparks when you are working in the drill. These motors are used in both hammer drills as well as impact drivers. So noise effects for both hammer drills as well as impact drivers.These are the noise rather than the bearing noise which occurs in both brushed and brushless drill motors.

- High damage ratio – Brush scraping the commutator when there are dust particles. Because of this commutator, brushes can be damaged. And also, it can damage the inside coil’s coverings. So there is a high damage ratio in the brushed drill motors.

- Torque can be lost – Due to the reverse EMF, the motor starts generating a voltage reverse which acts against the supply voltage. Thus the current flow is reduced, which, in turn, reduces the strength of the magnetic field, which provides the turning torque.

Advantages and Disadvantages of Brushless Drills

Advantages of Brushless Drills

- No Heating Issue – Brushed motors presence electromagnetic in the center of the motor, and they do not cool quickly. But brushless motors do not have an electromagnet in the center, and there is no heating issue.

- No Spark – Brushed motors are with spark due to the commutator and brush scratching each other. But in the brushless motors, there is no any contact surface. Hence no sparks.

- Least Noise – When a motor is rotating, there are two types of noises—mechanical and electromagnetic noise. Normally small motors do not produce much electromagnetic noise but mechanical noise. Brushed motors produce the scratching noise of the brush and commutator. But brushless motors do not have this. In the brushless drills, there is bearing noise only. Which is common for both

- High Efficiency – Brushless motors are highly efficient than brushed motors due to low energy wastage and their mechanism. Its efficiency is more than 25% of the brushed motors.

- Provide Maximum Torque – Brushless motors can provide more torque rather than brushed motors. If you need to take out the same torque from the brushed motor, you will need a bigger magnet. This means a small space can have the maximum torque using the brushless motors. Torque is the most important factor for impact wrenches.

- Low Maintenance – Brushless motors are not damaged by dust and abrasion. Therefore there is a low maintenance cost for the maintenance.

- Can Control Speed and Torque – Brushless drill motors can provide adjustable speed and torque. This causes longer work and efficient work.

- More LifeTime – Brushless drill motors have more lifespan than brushed drill motors.

Disadvantages of Brushless Drills

- Cost – Brushless motors are more cost rather than brushed motors. The motor is with a different mechanism, and it is more durable. Due to this, it is more cost rather than brushed motors.

- Replace instead of repair – Spare parts of the brushless drill motors are difficult to repair. There are small electrical components that are not able to repair. Instead of repair, we have to replace.

- Vibrations occur in low speed – When a brushless DC motor is operated at a low speed, there is a vibration. When the speed is high, the vibration will reduce.

- Difficult to handle – Normally brushed motors are handle with the 2 wires (+, -). But in the brushless motors have 3 terminals. Those should be connected properly for working. Hence need additional technical knowledge for it.

Do Brushed Motors get Hotter than Brushless?

Normally, brushed motors get hot more than brushless ones. Due to the brushes touching the commutator it can be heated much. But in brushless drills there is no brushes and minimum heated is generated.

Is Brushed or Brushless More Powerful?

Brushless are more powerful than brushed. Becuase brushless does not have inside friction. Hence it generate maximum power it generate. Normally, it is efficient 25% than brushed.