Circular saw used for a wide range of wood cutting in the woodworking industry. When I use a circular saw I could face many problems. Among that wood surface burning is one of them. At first, I could observe that the wood was burning and the smoking rising. I could find so many reasons for circular saw burning wood.

Generally, circular saw burning wood due to improper supporting, dirty saw blade, Dull and blunt saw blade, lower cutting speed, bent saw blade, harder workpiece, poor blade alignment, and poor techniques. It can fix by using a good quality saw blade with suitable cutting speed and techniques.

Burning marks can be seen on the cutting surface of the workpiece. It can be seen due to higher friction between the saw blade and the workpiece. When the friction is increased, heat generation also increases significantly. As a result of this wood, the surface can burn due to heated saw blades.

1. Misaligned Circular Saw Shoe, Saw Blade, and Guide Fence

Although you have a proper saw blade, you can see some burning marks on the cutting surface. The most reason is misalignment with the saw blade, shoe, and guide fence. When cutting circular saw, we have to push forward. In order to have an accurate cutting path, we can use a guide fence. When the saw blade, shoe, and fence are not aligned, we have to push hard. This will cause burn marks on the cutting surface.

When pushing hard, one side of the saw blade can thoroughly touch the saw blade. Hence surface can heat too much. The result will be a burning surface.

Due to these factors, it is difficult to cut straight using a circular saw.

Solution – Align the saw blade, shoe, and guide fence with zero tolerance.

2. Lower Feed Speed and High RPM

A circular saw should be fed to the workpiece. When the circular saw feeding speed and spinning rate are not compatible, we can see some problems.

Simply, lower feed speed and higher rpm will burn the wood. The reason is saw blade tends to rotate inside the workpiece too much time, and this will increase heat inside the kerf. As a result, this workpiece can burn, and we can see burning marks there.

When a dirty blade is used under this condition, the situation can be worst. Because dirty blades have more friction and will generate more heat.

Solution – Use sufficient feed speed and RPM for the circular saw-cutting process

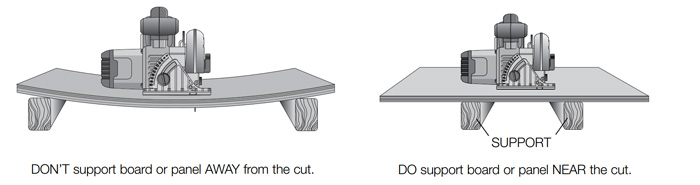

3. Improper Supporting on Workpiece

When you use a proper saw blade with proper cutting techniques, you can see some burning marks on the cutting surface. As a result of the burning wood, we can see smoke from the circular saw. This is happened due to improper support. The saw blade should not clog by the workpiece during the cutting process.

This happens when tension occurs on the workpiece. Both ends supported wood pieces can be bent due to their weight while cutting it. When a workpiece is bending, we can see compression on the upper fiber layers and tension on the lower fiber layers. When a workpiece is cut from the middle, the saw blade will get stuck due to the compression of the upper fiber layers.

As a result of this workpiece, force to the saw blade from two sides. So saw blade will move hardly. As a result of this, additional friction is generated. Due to the additional friction and moving saw blade more heat can be generated. Finally, we can see burning or scorching marks on the workpiece cutting surface.

Solution – When you cut the workpiece keep the support distance less than 1 ft.

4. Dirty Circular Saw Blade

When a brand new saw blade is used for a long time, wood dust can adhere to the saw blade surface. As a result, we can see an additional dust layer is toughly attached to the saw blade surface, teeth, gullets, etc.

Because of this, saw blade thickness can increase badly. When the saw blade is spinning, these excess layers are touched with the cutting surface. This will cause additional friction force. The final result is increasing the heating. Due to the heat generation, these attached dust can spread on the cutting surface. Due to the higher thickness of the saw blade, heat will generate, and we can see burn marks on the cutting surface.

When the saw blade is dirty, we are not able to feed the circular saw due to high friction.

Remember – Do not use a wire brush or grinder to clean the saw blade. It will make the saw surface rough, and the result will be more friction surface.

Solution – You can use saw blade cleaners to remove the adhered dust on the saw blade surface. You can use 409 as a saw blade cleaner.

Read More About – Top 05 Circular Saw Problems and Solutions

5. Harder Workpiece

A harder workpiece can burn the workpiece. Most of the wood-burning can be observed during the crosscuts. When a saw blade is used to crosscut, we can see burning marks. Because cross cuts are harder than rip cuts.

When the workpiece is hardwood, this will be the worst.

Hard Wood

- Oak

- Maple

- Cherry

- Birch

- Aspen

- Alder

- Sycamore

Solution – Should use a higher number of teeth to cut the harder wood and a lower number of teeth for softwood.

6. Bent Circular Saw Blade

Due to unexpected problems, a saw blade can bend. This is probably happening in the low-quality saw blades. If a saw blade has bent any point, That place will hardly touch the workpiece cutting surface. As a result of this, we can see burn marks on the side of the cutting surface.

Solution – Replace the saw blade for a new one.

7. Misalignments of the Circular Saw Blade

The saw blade should be perpendicular to the arbor shaft. Else it will wobble during the spinning. As a result, we can see burn marks on the cutting surface, and sometimes we can see wider kerf. So always keep the saw blade properly aligned.

8. Poor Cutting Techniques When Using Circular Saws

If you are a newbie to use a circular saw, check the cutting surface after cutting it. If there are burn marks, should pay attention to the below factors.

When a newbie uses a circular saw, it can move here and there slightly due to a lack of user experience. As a result of this, we can see circular paths and crooks. This will cause to the burning of the workpiece.

Solution – Use a fence or track until you are compatible with the circular saw.

How to Prevent Circular Saw Burning?

You can prevent circular saw burning by following these steps

- Use a sharp circular saw blade

- Select the right circular saw blade

- Adjust the circular saw blade speed

- Use proper feed rate for circular saws

- Use cooling lubricants on circular saw

- Check circular saw alignment

- Allow circular saw blade to cool