When we need to drill concrete, we need a special drill bit that withstands to high impact force and resistance. Concrete consists of aggregate, cement, and rebars. When we need to drill concrete and rebars, we need a special drill bit. So let’s see what are those drill bits for concrete and rebars with, considering all the other factors you should know.

So let’s see, what you should know before selecting a drill bit. We can drill concrete and rebars separately as well as together. So let’s see, how we can do it.

When you drill concrete, you will need a harder and tough masonry drill bit rather than concrete. Mostly, rebars also included in the concrete.

Concrete and Rebars Drilling Methods

When you drill concrete and rebars, you can do in 2 methods using masonry drill bits.

- Method 01

First, you can drill concrete, use a rebar cutter to cut the rebars, and then drill the remaining concrete.

- Method 02

You can use a higher-performance SDS max drill bit to drill both concrete and rebars together.

You can use an SDS max drill bitIf you have an SDS max drill or rotary hammer. If you have a regular drill bit, you can go through method 1. So you can choose the suitable drill bit from the below list.

I have clearly explained Method 1 and Method 2 in detail at the bottom of this article.

Best Drill Bits for Concrete and Rebars

1. Bosch HC5071

BOSCH HC 5099 Drill bit is highly designed for the SDS max drill bits that can drill both concrete and rebars together. Its material is carbide and alloy steel mixture. Due to the carbide and Alloy material, it can withstand higher hammer function as well as its durability is longer. Due to the centric tip, it can drill through the hard material with higher accuracy. Inclined side cutters will provide aggressive fast cutting into the material.

| Name | BOSCH HC5071 |

| Rating | 4.7 Out of 5; Rating – 1504 |

| Available Sizes | 1″, 1 1/2″, 1 1/4″, 1 1/8″, 1/2″, 1 3/4″, 1 3/8″, 3/4″, 2″, 3/8″, 5/8″, 7/8″, 9/16″, 11/16″, 13/16″ |

| Length | 13″, 21″, 29″, 36″ |

2. DEWALT DW5820

Dewalt (DW5820) SDS Max drill bit is one of the most used longer drill bits which is used to drill deeper concrete. It has a carbide tip and a 31-inch flute length. Stronger 4 end cutters will cut the concrete and rebars easily. Normally it is 2 times longer life than the Dewalt SDS hammer drill bit.

| Name | DEWALT SDS Max (DW5820) |

| Rating | 5 Out of 5; Rating – 16 |

| Available Sizes | 1″ |

| Length | 36″ |

3. KATEYA SDS Max

KATEYA SDS max drill bits come as 07 pieces package. Drill bit tips are made with carbide, and they can fix into an SDS max hammer drill perfectly. These are not able to use in SDS, SDS Plus drills. Tips consist of 4 high-grade carbide cutting points for rapid and precise drilling. Tips are forged from high-speed steel and precision tempered. Due to the carbide and HSS, its durability is higher than other drill bits.

| Name | KATEYA SDS max |

| Rating | 4.5 Out of 5; Rating – 91 |

| Available Sizes | 1 1/2″, 1 1/4″, 1 1/8″, 3/4″, 5/8″, 1/2″ |

| Length | 13″ Drill Depth 9″ |

4. Dewalt DW5470

Dewalt (DW5470) SDS max drill bit coming as a 05 pieces package. Its tip is made with carbide and it can withstand concrete and rebars easily. Due to the two-stage flute design with variable helix pattern of the drill bit can remove the debris efficiently. A weak mark indicator will increase the accurate diameter of the hole. The tip consists of Rock Carbide, which increases the durability of the tool.

| Name | Dewalt (DW5470) SDS max |

| Rating | 4.5 Out of 5; Rating – 1536 |

| Available Sizes | 3/16″, 1/2″, 1/4″, 3/8″ |

| Length | 4″, 6 1/2″, 6″ |

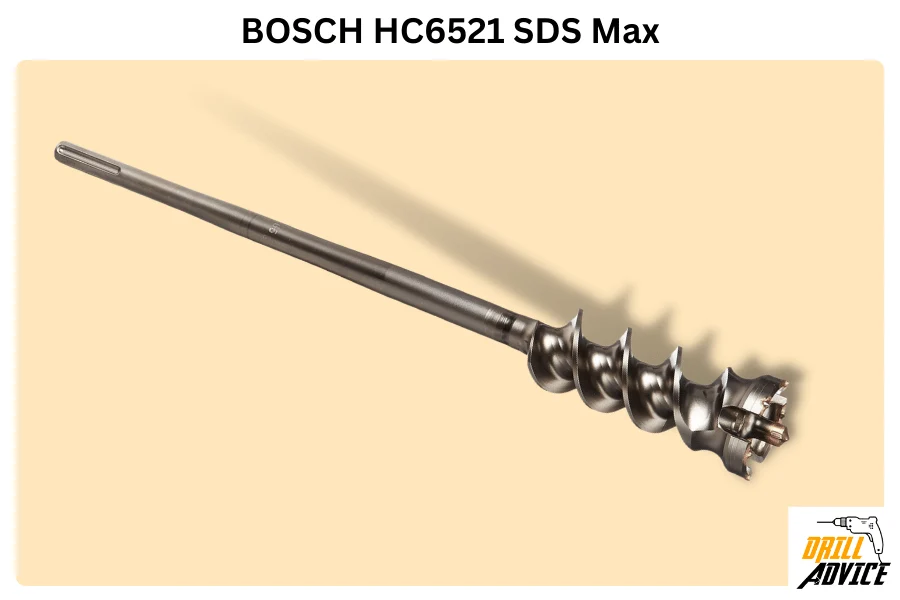

5. BOSCH HC6521 SDS Max

BOSCH HC6521 SDS max drill bits have 2 1/2″ diameter of the tip. Drill Bit is made with carbide and it will increase the durability and withstand the hammering action of SDS max drill. This will fix to 1 3/4″ chuck of SDS Max drill. It can be used for concrete, reinforcements, bricks, stones, etc.

| Name | BOSCH HC6521 SDS max |

| Rating | 4.4 Out of 5; Rating – 104 |

| Available Sizes | 2 1/2″, 3 1/8″, 2 1/8″, |

| Length | 24″ Drill Depth 18″ |

6. Irwin Speedhammer SDS Max

Irwin Speedhammer SDS max drill bit is made with chrome and carbide. Its hardness is incredible with a carbide tip. The body of the drill bit is made with a chrome vanadium body. These materials these highly heat resistant in durable. This can be used in concrete, granite, and very hard material.

| Name | Irwin Speed hammer Sds Max Drill Bit |

| Rating | 4.4 Out of 5; Rating – 104 |

| Available Sizes | 1 1/2″, |

| Length | 15″ |

7. Diablo – DMAPL4250 (SDS Plus)

Diablo – DMAPL4250 SDS Plus drill bits can be used to drill concrete. But this can’t be used for drilling both concrete and rebars together. You will need a rebar cutter to drill both materials in two steps. This is made with carbide and will increase the tool’s durability. And also, there is a 4-cutter full carbide tip.

| Name | Diablo – DMAPL4250 SDS Plus |

| Rating | 4.4 Out of 5; Rating – 63 |

| Available Sizes | 3/4″, |

| Length | 10″ |

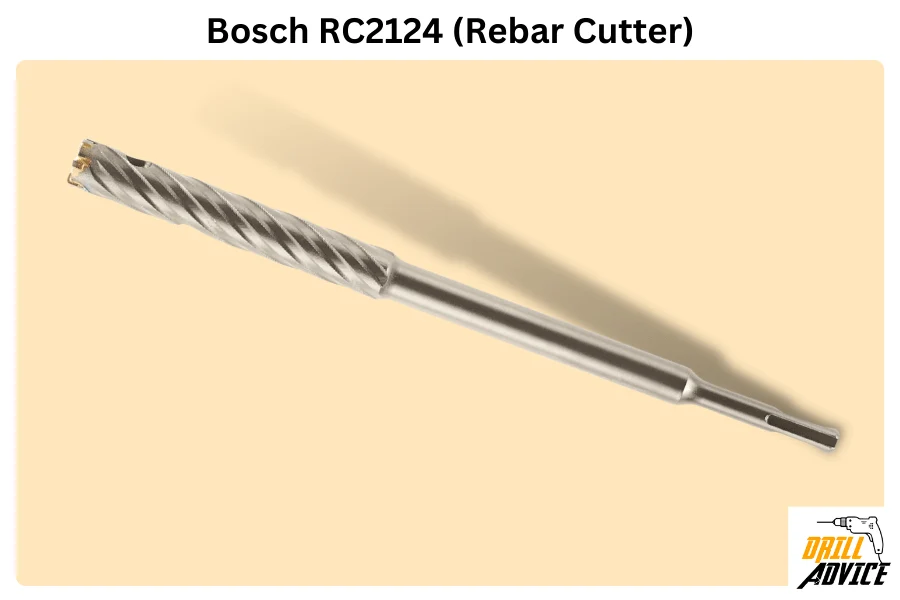

8. Bosch RC2124 (Rebar Cutter)

Bosch RC2124 is a rebar cutter that can be used for drilling rebars inside the concrete. This can be used in SDS plus drill. Cutter is made using carbide. You will need an SDS plus drill bit to drill the concrete and additionally, a rebar cutter can be used to drill inside reinforcement. Due to the carbide tip, it will last long and resist high heat and friction. The unique flute geometry will remove the debris fastly.

| Name | Bosch RC2124 (Rebar Cutter) |

| Rating | 4.4 Out of 5; Rating – 314 |

| Available Sizes | 1″,1 1/2″, 1 1/4″, 1 1/8″, 3/4″, 5/8″, 1/2″, 9/16″, 7/8″, 3/4″ |

| Length | 12″ |

9. BOSCH RCSS2164 (Rebar Cutter)

BOSCH RCSS2164 (Rebar Cutter) is another tool for drilling inside rebars successfully. Bar cutter finish type is made with titanium. Overall this is made with carbide and high-speed steel. Due to the high-quality material, it will last long with higher resistance. The tapered body design provides less weight for smooth drilling.

| Name | BOSCH RCSS2164 (Rebar Cutter) |

| Rating | 4.4 Out of 5; Rating – 29 |

| Available Sizes | 1″,1 1/2″, 1 1/4″, 1 1/8″, 1/2″, 3/8″, 7/8″, 9/16″ |

| Length | 12″ |

How to Drill Concrete and Rebars?

Concrete is a high-hardness material that can be drilled with one drill bit or two drill bits when drilling a slab with a metal frame such as an iron wire. Concrete can be strong under compression but has poor tensile strength. In order to increase the tensile strength of the concrete, rebars are used.

So obviously, the hardness of concrete and steel is different. The types of concrete used in different constructions are different. Accordingly, the hardness also changes. Rebars of various diameters are available for purchase on the market.

The levels of hardness are as follows.

| Application of Concrete | Hardness (PSI) |

| Nuclear Plants | ≤8000 |

| Bridges | 60000-8000 |

| Roads | 4000-6000 |

| Sidewalks, Parking lots | ≥3000 |

Introducing steel wire into the concrete in the form of a wire mesh slows down cutting or drilling and prolongs the life of the blade or bit. Concrete-containing reinforcing steel costs more to cut.

The hardness of the rebar with the highest carbon content is 290.0 HRC and the hardness value of rebar with the lowest carbon content is 232.2HRC. The minimum standard hardness of the rebar is estimated at 13.48HRC.

So let’s see, how to drill such concrete separately.

Method 01. Using a Concrete Drill Bit

Concrete can usually be drilled using a hammer drill or rotary hammer and a masonry drill bit.

First step – First, determine where to drill the hole or holes in the concrete. Mark the area or places where the holes should be.

Second step – If you are using a cordless drill, it must be fully charged. If you are using a corded drill, it should be easy to set up.

Third step – After that, insert a carbide or diamond-tipped masonry drill bit into the hammer drill. Loosen the drill wheel, insert the drill bit into its end, and tighten the drill wheel back up.

Fourth step – The drill bit should be directed directly at the marked locations on the concrete and activated. Slow drilling should begin.

By drilling slowly, the marked area can be drilled slightly, and the concrete can be subjected to rapid drilling with high pressure.

Method 02. Using a Concrete Drill Bit and Rebar Cutter

A rotary hammer drill bit cannot go through the rebar. Therefore, load to the rotary hammer drill and use a rebar cutter drill bit with the same diameter and drill until it passes the rebar. After that, unload the rebar cutter drill bit and continue drilling using a rotary hammer drill. According to the appearance of the rebar cutter, it can be used for cutting and bending metal.

Features of rebar cutter

- Tungsten carbide tipped teeth.

- Relief hole for slug removal.

- The spiral flute removes debris fast.

- SDS plus shank

Method 03. Using a Cabite Tip Drill Bit

Using two different drill bits in two situations can be introduced as an efficient measure. Therefore, by using a drill bit with high hardness, a hammer drill that can do the work of drilling with the high torque of the SDS type can drill concrete as well as rebar.

The tip of the SDS plus drill bit with 4 cutters should be centered and aimed at the place to be drilled. Drilling should not be stopped if a rebar is encountered during drilling. The applied torque can be increased to complete the drilling.

- If the cross-sectional area of concrete is 1% steel, blade life is shortened by about 25%.

- A concrete slab with 3% steel can reduce its lifespan by up to 75%.

So, suitable drill bits:

- SDS plus drill bits with masonry carbide tips

- SDS max drill bits with masonry carbide tips

Those drill bits have the robustness to last for a long period of time.

The two-cutter design of the tip of these bits can be used efficiently when drilling only concrete.

But if you want to drill rebar after concrete drilling, the four-cutter design is suitable. Also, the tip of the drill bits suitable for cutting the best rebar in the world should be made entirely of carbide.