You can properly sharpen the drill bit by using these 9 methods such as using hand, using a file, sandstone, angle grinder, bench grinder, sharpener, homemade sharpener, dremel and a belt sander.

Before you start to sharpen the drill bit, you should make sure by observing the drill bit cutting angle, removing chips and the type of the drill bit. If the drill bit point angle is dull or blunt and the ejected chip size is less than 2mm drill bit should be sharpened. Most of wood and metal drill bits can be sharpened, and masonry drill bits are not able to sharpen. You should not try to sharpen the coated drill bits due to their performance loss.

You can sharpen the drill bit using the below 9 methods and using these 3 essential tools such a sharpener, vise and drill bit angle gauge. Sharpening tools are essential for the sharpening process. The vise is used to tighten the drill bit and an angle gauge to measure the drill bit cutting angle.

How to Sharpen Drill Bit by Hand?

You can follow the below 08 steps for resharpening a drill bit by hand. You will need a drill bit angle chart to determine the drill bit angle that you need.

- You slide a drill bit into the jig to sharpen it.

- So that the end of the drill is slightly overhanging the edge, make sure the drill bit fits snugly into the slot. It should fit directly into the center groove on your jig.

- Then, place the tip of the drill near the grinding wheel. But please don’t press the drill bit tip against the grinding wheel until the grinding wheel is turned on.

- Sharpen the drill bit tip using a bench grinder or a rotary tool with a grinding attachment.

- Move the drill bit back and forth across the grinding wheel while maintaining a 60-degree angle.

- Maintain the wheel’s motion in the same plane as the drill bit’s cutting edge.

- If you have a lot of grinding to do, dip the tip of the drill in water every minute or so to ensure it stays cool.

- Continue grinding your drill bit until the edges are even.

Sharpening a drill by hand can be challenging because it is important to grind the correct angle.

You can use a jig to grind your drill bit to the proper angle. If you don’t have a jig, you can sharpen the drill bit using your hand with adequate practice.

Read More About – Drill Bit Sharpening Tools

How to Sharpen Drill Bit with a File?

You can sharpen the drill bit with using file by following the below 7 steps.

- Wipe out all debris or dust on the drill bit before you start sharpening it with a file.

- The drill bit should then be secured in a table vice so that you may file it while keeping it steady. If you don’t have a table vice or clamp, you can make do by firmly grasping the bit’s base.

- Since the bit has two blades on each side, you need to pay attention to the type of file you are using.

- A regular triangular small file should be used for long brad point drill bits.

- A mill file should be used for a spade bit.

- After sharpening, check the angle of the tip with a protractor or angle gauge.

- Using the filing tool, repeatedly run it down the edges of the bit until it starts to sharpen.

When you sharpen a drill bit with a file, you need tools such as a file, vice, and a drill bit angle gauge.

How to Sharpen Drill Bit with Stone?

You can sharpen the drill bit using stone by following these 6 steps.

- Choose the proper stone: Choose a sharpening stone with the proper size as your drill bit.

- Add a tiny quantity of lubricant to the sharpening stone, such as honing oil or water, to aid in accomplishing a smooth sharpening and prevent the bit from overheating.

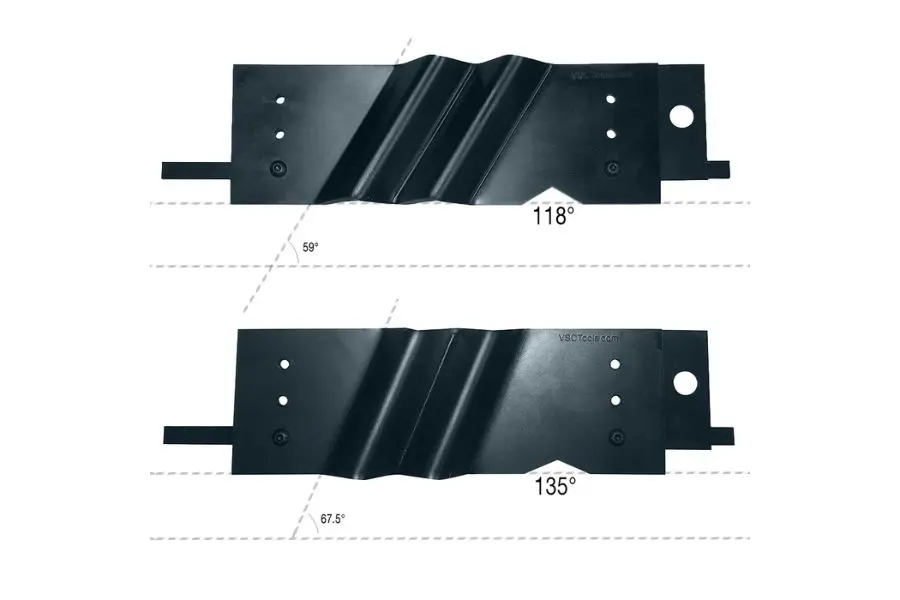

- Hold the drill bit at the proper angle- Which for a common twist bit is typically around 590. You might utilize a drill bit guide to maintain the proper angle.

- Sharpen the drill bit by placing it against the sharpening stone and rotating it in a circle back and forth. Lightly press the bit while avoiding overheating it.

- Continue the re-sharpening process until the bit’s whole cutting edge has been honed.

- Clean the drill bit to remove any metal shavings or debris from the sharpening process.

This method of drill bit re-sharpening can be done easily and with minimum accidents at home. The ideal material for the stone would be silicon carbide or aluminium oxide, both of which are tough and long-lasting.

How to Sharpen Drill Bit with a Bench Grinder?

You can follow these 07 steps when sharpening the drill bit using a bench grinder.

- To match the angle of the bit you wish to sharpen, adjust the angle of the grinder’s tool rest. The bit will be more evenly ground as a result of this.

- With a drill bit holder or a set of pliers, firmly hold the bit in place.

- Turn on the grinder contact with the grinding wheel with the bit’s tip.

- To prevent overheating, use a mild touch and rotate the bit back and forth.

- The bit should be ground until a fresh, sharp edge replaces the old one. Avoid grinding away too much material, as this can reduce the bit’s lifespan.

- Check the angle of the freshly sharpened edge after switching off the grinder. Adjust the tool rest and go through the grinding procedure again if it’s uneven.

- Drilling a hole in a waste material will allow you to test the newly sharpened bit. The sharpening procedure was effective if the drill operated smoothly and accurately.

Using a bench grinder to sharpen a drill bit is a popular and efficient technique. The bit must be handled carefully and with considerable skill, so taking the right precautions is crucial.

How to Sharpen the Drill Bit with an Angle Grinder?

You can sharpen the drill bit using angle grinder by following these 7 steps.

- Hold the drill bit firmly and the cutting edge parallel to the grinding wheel’s front.

- Slowly, carefully, move the bit forward until it engages the wheel.

- Simply hold it upright and at the original factory angle of 60 degrees without turning or twisting it.

- If you have a lot of grinding to do, dip the drill’s tip in water after a few seconds or so to ensure it stays cool.

- Continue grinding your drill bit until the edges are even.

- When satisfied with the point on the first side, turn the drill 180 degrees and follow the same process as above for the opposite side of the nozzle. To ensure even sharpening, one can gradually sharpen both sides by holding the drill bit in one’s dominant hand and rotating it 180 degrees after grinding every few seconds.

- Check the bit with a test run. Even with light pressure, a well-sharpened drill should create the beginning of a hole. If not, recheck the tip and sharpen again, angled to 60 degrees at the point with equal width on both sides.

Re-sharpening a drill bit using an angle grinder can quickly and effectively get your bit back in good shape. You can take the following actions:

How to Sharpen the Drill Bit with a Sharpener?

In addition to the above, you can use various methods and tools to sharpen drill bits. Another option is to use a drill bit sharpener. Drill bit sharpening machines are specially designed for sharpening drill bits. It consists of a small motor, a grinding wheel and a guide to hold the bit. The following steps should be followed to sharpen a drill with a sharpener.

Drill doctor DD750X drill bit sharpener is one of the best products you can use as a drill bit sharpener.

Details of the product:

- Grinding Material: Carbide

- Shank type: Straight

- Cutting angle string: 1150 – 1400

- Main two steps of the sharpening procedure according to the manufacturer;

- Align – Align ensures the precise geometry and measure amount to be removed.

- Sharpening

- Options step; Split the point

How to Sharpen Drill Bit with a Home-Made Sharpener?

You can follow these 06 steps using a homemade sharpener when you resharpen the drill bit.

- Check the tip of your drill bit. Under that, check the chisel, landings, and edges of the drill bit.

- After that, hold your drill bit on your homemade jig.

- Hold the drill bit firmly and the cutting edge parallel to the front of the re-sharpening tool.

- Dip the drill’s tip in water after a few seconds or so to ensure it stays cool. Continue the process with your drill bit until the edges are even.

- Turn the drill 1800 and follow the same process as above for the opposite side of the nozzle.

- Check the bit with a test run. If not, recheck the tip and sharpen it again.

Here mentioned how to make a jig with your limited resources at home.

If you don’t have a jig, follow the procedure below to make a jig quickly.

- Take any durable piece of scrap wood you have around. It should be about a foot long and about four inches wide.

- An angle of 118 degrees is ideal for drill bits. For that, you need to create a 590 angle on your jig. Measure and mark your wood before cutting it.

- Cut the slot along the mark and check the slot size with your drill bit.

How to Sharpen a Drill Bit With A Dremel?

You can follow these 3 quick steps to sharpen the drill bit using the dremel

- Clamp your bit down firmly in a bench vise, and then use the Dremel to progressively remove the debris from the leading edge of the bit.

- After you have a clean, sharp cutting tip, keep grinding. Make sure to apply this on both sides of your bit as well.

- Verify the drill bit is sharp. If you detect any wobbling, squealing, or jagged edges, you must to go back to the Dremel to round them up. It should be simple to drill and give you a smooth hole.

Dremel is the rotary tool. It can also be used for carving, engraving, routing, grinding, cleaning, polishing, cutting, sanding, and sharpening. It is a very useful tool for home use.

How to Sharpen a Drill Bit with a Belt Sander?

You can sharpen the drill bit using the belt sander by following the below 6 steps.

- Cut the landing,

- Shape the chisel,

- Shape the landing of the drill bit.

- Combining cutting, shaping and rotating is very important while sharpening to make the perfect cut on the drill face.

- To sharpen the other lip, repeat the previous process a few times while turning the drill bit 180 degrees in your hand.

- Cool the drill bit after every few seconds during the drilling process.

While using a belt sander to sharpen drill bits might be quick and simple, it does need some expertise and practice to do it successfully.

What Causes to Blunt a Drill Bit?

A drillbit can be blunt or dull due to these 6 ways.

- Overheating the drill bit – Overheating is one of the most common causes of drill bit bluntness. When a drill bit is used excessively without proper cooling or lubrication, it can become extremely hot. This heat can cause the metal to soften and lose its sharpness.

- Drill into hard and tough materials – Drilling into hard materials such as steel or concrete can cause a drill bit to become blunt. The high resistance and friction can wear down the sharp edges of the bit.

- Use incorrect drilling speed – Using the wrong speed can cause a drill bit to blunt. If the speed is too high, it can cause the bit to overheat and lose its edge. If the speed is too low, it can cause the bit to wear down prematurely.

- Using a poor quality drill bit – If the drill bit is made of poor quality material, it is more likely to become blunt. High-quality drill bits are typically made of strong, durable materials that can withstand the stress of drilling.

- Improper storing the drill bits – Drill bits can become blunt if they are not stored properly. If they are thrown into a toolbox or drawer without any protection, they can rub against other tools and become dull.

- Lack of maintenance the drill bits – Regular maintenance such as cleaning and sharpening can extend the life of a drill bit. Neglecting this maintenance can lead to the bit becoming blunt. Dirt, rust, and other debris can accumulate on the bit, causing it to dull over time. Similarly, failing to sharpen the bit regularly can also lead to bluntness.