Impact wrenches are used for lug nut tightening and losing. When you use an impact wrench, some problems can occur due to electrical and mechanical problems. An impact wrench can heat due to many problems. So let’s see what are the reason for the impact wrench overheating while you using it.

An impact wrench can overheat due to many reasons. Below are the reasons and how I fixed it within a minute. So let’s check it out. In this guide, I discuss all about electric cordless impact wrenches overheating problems and quick answers you can follow.

What is Impact Wrench Overheating?

Impact wrench overheating is a condition when the tool becomes excessively hot during operation. This can occur due to several reasons such as continuous use for extended periods, applying the maximum loading during the use, lack of lubricating, worn carbon brushes, inside debris, ventilation covering, electric short and bearing problems. Overheating can cause damage to the internal components of the wrench, decrease its efficiency, or even lead to complete tool failure.

What are the Reasons and Solutions for Impact Wrench Overheating?

1. Using Impact Wrench Continuously

When a tool uses it generates heat. Generated heat should be removed quickly. If the generated heat is not removed quickly it can overheat. So when you work a long time you can feel the tool has overheated due to this reason. You can let the tool cool and then start the work again. Do not use any liquid or any method to cool the tool. Let it cool naturally.

Solution – Do not use impact wrench continuously. Let it cool when you feel it is heating up

2. Impact Wrench is Operating Under the Maximum Power

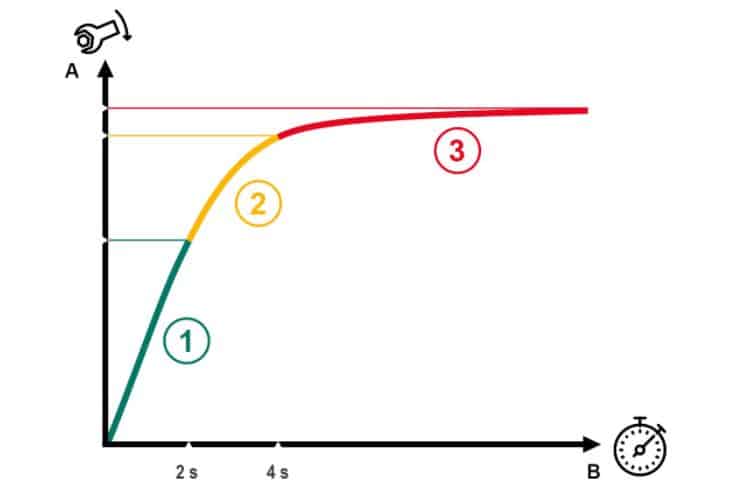

Impact wrenches have three types of torque generations.

Optimal torque – Best productivity torque

Working torque – Maximum working torque

Maximum torque – Maximum torque that tool can produce

When an impact wrench is working under the maximum torque, it needs to produce maximum power. So tool can overheat in this range. Do not work in this range much time.

Solution – Do not work on maximum torque. Work on the working torque as much as possible.

3. Lack of Lubricants in the Impact Wrench

Lubricants can do two main things. It can transfer the heat, and it can reduce friction. When the surfaces are touching each other heat can rise. Due to this reason, lubricants do amazing tasks. So if there is no lubricant surface will heat due to friction, and then it will overheat. So use the recommended lubricant after a regular period.

Solution – Apply the lubricants when you serve them. At least service once a month if you use it regularly.

4. Impact Wrench Carbon Brushes are Worn Out

Impact wrenches consist of brushed motors or brushless motors. The brush touches the commutator while it is rotating. It produces heat due to friction. As a result of this brushes can wear. When a brush is worn it is unable to touch the commutator properly.

So commutator brushes heat due to friction. When this is happening continuously it’s heating up.

solution – Remove the brush when it reaches the length 1/4 of the original length

5. Impact Wrench Ventilations Covering

Ventilation is really important. It can transfer the heat as hot air. If the ventilation is blocked and hot air is not able to transfer properly. So inner heat can be increased due to ventilation coverings. Sometimes ventilation covering with the hand when we use it as well as it can clog with the dust also.

Solution – Use your hand properly as it does not cover the ventilation. Clean the holes when you serve them.

7. Electric Shorts in the Impact Wrench

Due to some reasons, inner coils, wires, and circuits can be damaged and electricity can be leaked. So it can heat up. You can observe this by the battery losing power more quickly than in a regular time period.

Solution – Remove parts and check which have been damaged and insulate them. Else remove it.

8. Bearing Problem in the Impact Wrench

Bearings are used to support the free-end rotating. If there is a problem with the bearings, they can heat while it is rotating. So, make sure the bearings are working properly in your monthly service term.

Solution – Check and lubricant the bearings while you service the impact wrench.

How to Prevent Impact Wrench Overheating?

You can prevent impact wrench over heating by following the below steps.

- Regularly check and maintain the impact wrench to ensure it is in good working condition.

- Avoid using the impact wrench continuously for long periods of time.

- Allow the tool to rest and cool down after each use.

- Use the correct size and type of socket for the job to prevent unnecessary strain on the tool.

- Keep the tool clean and free of dust and debris which can clog the motor and cause overheating.

- Grease the impact wrench to reduce friction and heat build-up.