Table saws are very important cutting machines in woodworking. For accuracy and rapid cutting, we should use a table saw. According to the power, workspace, usage, performance, size, and user experience tables, saws are categorized into mainly 08 types. These types are used for different tasks and purposes. Before you buy a table saw, you should know which one is really compatible with your task. You can gain all in details about all available types of table saws in the market.

First, you can find the usage of the table saw and then the pros and cons of the table saw that you need. Additionally, problems, user experience, and other essential factors have been included here. So let’s keep reading on until the end.

What is a Table Saw?

The table saw is a woodworking tool that consists of a circular saw blade that is mounted on an arbor. Table saws are used to cut wood mainly. But specific table saws can be used to cut PVC, aluminium, metal, and tiles.

The invention of the table saw is credited to Samuel Miller in 1777, though some argue that its design was simply an enhanced version of the circular saw. In the late 18th century, the saw blade was incorporated directly into the machine. As a result of this, wood can be placed on the flat table and a crank could be used to raise or lower the blade as needed.

After decades carbide-tipped circular saw blade was invented and that increased the efficiency of the tool. Later, improved power sources led to the development of electric table saws, replacing earlier versions powered by treadle or steam. Today table saws are available as mainly 7 types according to size, power consumption, and purpose.

What are the 7 Types of Table Saws?

1. Mini Table Saw

As it explained by its name, it is small-size table saw. It is about 4-8 kg in weight and its power consumption about 90W-150W. It can operate by less voltage, such as 110 V, and mostly can operate by 220 voltage. Some mini table saws are available with 12V-24V DC. So you should not worry about the power consumption of this kind of table saw. The mini table saw uses fewer diameter saw blades, such as 4 inches.

A mini table saw can be used for the jewelry task mostly. It consists of many external tools such as a fiber wheel, grinding wheel, wood cutting disc, water cooling system, etc.

This kind of table saw is really important for jewellery-making people. So it consists of many essential types of equipment for jewelry making. Mini table saws can be used for woodworking also. Most mini tables are designed for both metal and woodworking.

If you have a tiny workpiece, you can use a mini table saw. Due to the saw blade diameter is less than 4-6 inches, you will not cut more than a 3-inch workpiece.

Pros

- Mini table saws are lightweight and carried anywhere

- Mini table saws are suitable for small-size tasks.

- Mini table saws have low power consumption.

Cons

- Due to the small size of the mini table saw, it is hard to clean after it is covered with dust.

- Miter would not slide on the groove due to clogging the dust.

- The saw blade cannot be adjusted due to its small size.

- If the mini table saw is designed for woodworking, its motor cannot be enough when you do metal workings.

- Sawdust is not removed properly in the mini table saw

- The motor can be overheated in a mini table saw due to higher loading.

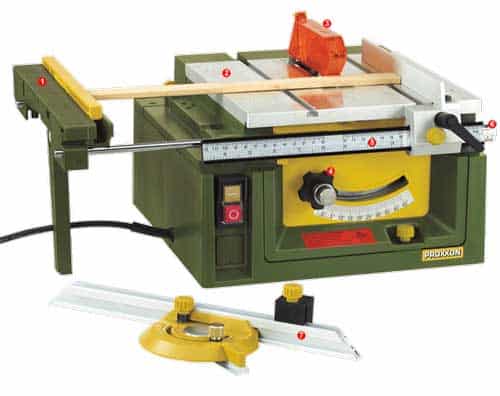

2. Benchtop Table Saw

As explained by its name, benchtop table saws are used on the support. Benchtop table saws have no supports or legs. it should be kept on the table as a support. Benchtop table saws are very famous for DIYs and domestic workers. Because it is lightweight and consumes lower power, and can be stored in a small area. Benchtop table saws can be used for woodworking mainly. Due to its lightweight, it can be carried to the workplace without any inconvenience.

Benchtop table saws are with regular saw blade, which has 4-6 inches saw blades. The saw table is really lacking space as a workpiece handle on the table saw top. The fence miter gauge is also not enough for hard-working projects.

The bench-top table saw is designed in a compact size, allowing the user to carry and hold it anywhere. Although it is portable, it is a highly vibrated tool. Because of the no supports or legs. In the regular benchtop saw table has 2-3′ rip capacity and is powered by mostly 15 amp and 220V battery.

If you need to use a benchtop saw table for a large project, you should make an additional support table with suitable equipment.

Pros

- Less weight and easy to carry

- Can be used for medium task

- Suitable for small cabinet works

Cons

- High vibration when it operates

- Limited work space

- Need a support to place the saw machine

- Difficult to clean when it is dusting

3. Compact Table Saw

Compact table saw is the largest portable table saw. It is much expensive than a benchtop table saw, and a mini table saw. The compact table saw has compacted all its parts together and this will easy to carry it everywhere. Using a compact table saw, you can handle more heavy tasks than benchtop table saws.

Due to the size and the portability compact table saw is powered by low voltage and amps. Mostly compact tables can be cut. You can cut 2-5/8 inch 0 bevel cutting depth.

The compact table saw has supported by a stationary stand. The motor can be powered by AC or DC. So you can use both AC and DC current with this kind of saw table. Motor power is transmitted to the arbor using a small tooth belt. The saw tabletop has been designed with cast irons, and it can reduce the workpiece and surface friction.

Using this, you can construct lighter constructions and really useful for DIYs and domestic projects.

4. Jobsite Table Saw

If you are a contractor, carpenter, deck builder, or home service guy, this is the best tool you should have. Jobsite table saw will cost about $500-$700. It is powered by corded electricity mostly. This is with 2-3 feet rip capacity.

As described by its name, it is really used in the workplace. Jobsite table saw is more weight, and more size than above saw machines. There is a handle and wheels to carry it any place easily. Most saws have foldable supports. Using these supports table can stand up and use.

The table saw top is enough to handle midrange workpieces. Because supports can be damaged if a high load workpiece is placed on the saw top.

Most parts are foldable due to transporting the tool. So these kinds of parts can be easily damaged due to less strength. Many parts are made with light materials in order to reduce the weight. When the support is consists of wheels, it can move a bit here and there.

As well as when the wheel bearings are worn tool balance can be observed. we can observe vibration when we are using this Jobsite table saw due to non-permanent fixed joints.

When you buy this kind of table, saw you must choose less noise, and proper dust control saw table. when you work out, these are the most attention problems.

Read More About – How I Use Table Saw in My Apartment? – No Noise | Dust

Pros

- Easy to transport

- Easy to essemble

- Suitable for temporary project

- High accuracy

- Light weight

Cons

- Saw table can be vibration

- Strenght is not enough for heavy works

- High noise

5. Contractor Table Saw

Before introducing the Jobsite table saws, cabinet saws are transported to the site by fixing wheels to the supports. These are called contractor table saws. Contractor table saws are more weight than Jobsite table saws. Contractor table saws can use for heavier tasks because of strong support and powerful motor. It is with wide rip area and a strong saw bed top.

The base of the contractor saw is open, and there is no cabinet. The motor is with 1-2 horsepower, and it is an exposed motor. The trunnion is mounted to the table rather than the cabinet saw. The contractor saw is a great machine for the woodworkers.

6. Cabinet Table Saw

This is a professional permanent table saw that we can use for woodworking. This is a heavy-duty machine, and it is more expensive. If you are a professional woodworker, you should have this. Cabinet saw is with a covered base, and there is a proper way to collect the sawdust. Safety instruments such as a splitter, reviving knife, and blade guard can be mounted properly to the cabinet saw.

Normally cabinet saw is powered by 5-7 horsepower motor. because of this, it can use for heavy-duty projects. The trunnion is mounted to the cabinet. This will incorporate the saw blade mount and allow for height and tilt adjustment.

Due to the totally covered cabinet, dust collection can be done properly. Cabinet saws keep the zero clearance with tabletop and workpiece. So this will gain fewer tears and splinterings on the cutting surface.

The ripping capacity is about 1.3-1.5 meters. The cabinet saw is powered by 220V voltage with a 15 Amps current. The most used blade size is 10 inches. When you use this cabinet saw, be careful due to table saw injuries because of the high performance.

If you wish to make fine cuts with high accuracy, you should use the cabinet saw.

Pros

- High accuracy

- High performance

- Used by proffesional users

- High noise

Cons

- If there is a injury, it can be severe

- High power consumption

- Heavy weight and permanent placing.

7. Hybrid Saws

Hybrid saws are not identified clearly because of less information. Normally hybrid saws are considered as middle-function table saw between contractor table saw, and cabinet saw. Generally, hybrid table saws are more weight than contractor table saw and less weight than cabinet saws.

Hybrid table saws are powered by a 1.5-2 hp motor, and cabinet saws are powered by 5-7 horsepower motors. V belt is used to transmit the motor power to the arbor. The trunnion assembly is the use of upper and lower supports.

Normally cabinet saws are mounted from the top of the cabinet, and hybrid saws are mounted from the bottom of the tables.

Hybrid saws are coming with full enclosures with some in an open-leg design. A full enclosure will definitely improve the dust collection. It is a great solution if you use it in a closed environment.

7. Sliding Table Saw

A sliding table saw is called a European cabinet saw, or panel saw. This is a kind of variation of the cabinet saw. Sliding table saws are used to cut large panels of wood sheets using sliding panels. If you wish to use this, I think you should have more experience in woodworking. Else, investing for this kind of table saw is really useless. If you are a professional woodworker, you can finish your task within dew cuts and time using this kind of high-performance saw table.

This is a heavy-duty saw table that can use as a permanent solution. Sliding table saws are really heavyweight and expensive. It will cost about $4000-$5000. There is a smooth table saw slider that can carry more weight and move very smoothly to the saw blade. This can provide high accuracy and high-performance output. Normally it can cut 75mm workpiece like butter.

Sliding saws are with the proper sawdust management system. All parts are made with aluminum, and the bed is made with cast iron. The sliding table saw has been designed perfectly without any rusting issues.

Read More About – 10 Reasons: Why Is Table Saw Smoking? [How I Fixed]

Pros

- Scoring blade ensures tear-out free cuts

- A quick clamp-on, extruded aluminum sliding table

- Miter fence positions 45° right or left with two flip stops for repetitive cutting

- Precision-ground cast-iron main table with extensions

- Single-lever locking fence

Cons

- Heavyweight and expensive

- Use for proffesional usage

- More power consume