During your construction, you may need to drill the concrete for screws, anchors, nuts, or any other essential purpose. When you need to drill concrete, you should have suitable tools such as a drilling machine, drill bit, safety instruments, and dust removers for the perfect task. You can drill smaller diameter holes as well as larger diameter holes using modern drilling tools.

Most of the drilling tools have been specially designed for the concrete task because concrete is a very tough material. Normally, concrete has a crushing strength of 15 MPa, 20 MPa, 25 MPa for domestic purposes, and some high-strength concrete is available for special projects.

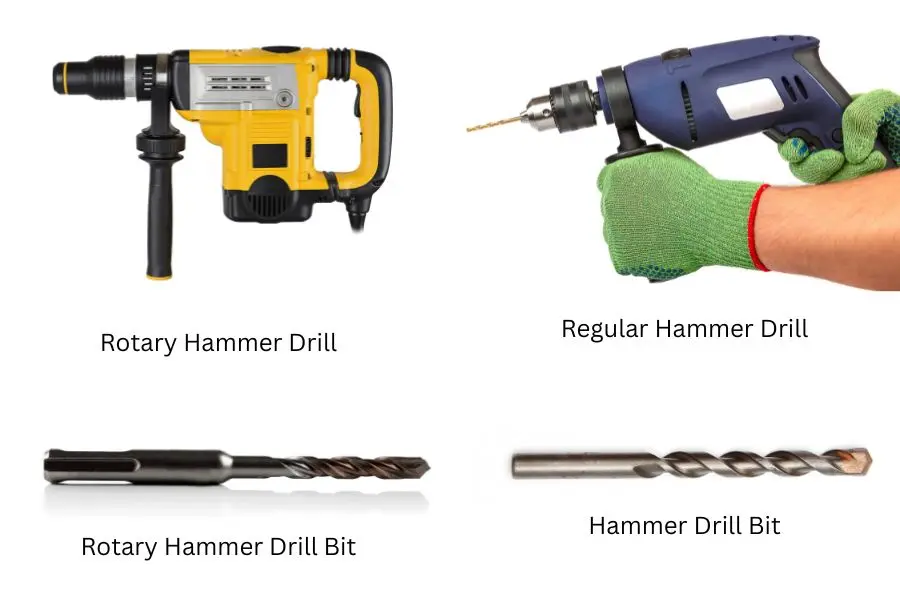

When you drill concrete, you can see many types of drills and drill bits. These tools have special mechanisms and structures to drill concrete. So let’s see, how to drill concrete?

1. Choose a Hammer Drill as a Concrete Drilling Machine

When you drill into concrete, first, you must know which drilling machine you should choose. Normally, electric drills are two types, regular drills, and hammer drills are them.

- Regular drills are just rotated around the drill bit axis.

- Hammer drills rotate around the drill bit axis and move forward and backward along the drill bit axis.

Using a hammer drill can give you a huge advantage. Due to the hammering action, it can crush the front material of the drill bit into small pieces.

Due to the rotational mechanisms, crushed particles will come out through the drill bit flute. This helps to drill the hard concrete easily and efficiently.

There are types of hammer drills according to the hammering power.

| Drill Machine | Hammering Power |

| Regular hammer drill | Low |

| SDS drill | Intermediate |

| SDS Plus drill | Medium |

| SDS max drill (rotary hammer drills) | High |

SDS drills are highly recommended for stone and bricks drillings.

2. Choose a Masonry Drill Bit as a Concrete Drill Bit

When you select a drill bit for concrete, you should select a masonry drill bit. Those are specially designed for impact mechanisms and hard materials.

Masonry drill bits are made with harder materials such as high-speed steel, titanium, and carbon. Masonry drill bits are made with combined materials such as titanium carbide.

The strength has improved at the tip of the masonry drill bit in order to resist high friction and heat.

Normally, masonry drill bits have wider spirals and blunt but stronger tips. More than cutting the materials, the blunt tip helps to crush and remove them through flutes.

Some masonry drill bits can be used for both concrete and metals. These drill bits can be used to drill inside the rebars.

Read More About – 09 Best Drill Bits For Concrete and Rebars

According to the shank structure, masonry drill bits can be classified as regular masonry drill bits, SDS plus drill bits, and SDS max drill bits.

Before you choose the drill bit, make sure whether the drilling machine can fit that.

Because SDS plus can fit into SDS plus drills, and SDS max bits will fit on the SDS max drill bit.

When you need to drill larger diameter holes, you should use hole cutters. Hole cutters are made with carbide teeth, and their size is more than 1 inch. Using that, you can drill a limited length.

3. Wear Safety Instruments for Concrete Drilling

When you drill concrete, you should have proper personal protective equipment (PPE). When you drill concrete, you should wear a safety helmet, safety glasses, dust masks, gloves, and earplugs.

When you use a hammer drill, it can produce higher vibration. As a result of this, some particles will lose and may fall onto the head. Hence, a helmet is very important. Small debris and dust can harm your eyes and lungs badly. Hence you should wear safety glasses and a dust mask.

When you wear safety gloves, you can prevent them from electric shock and work with lower vibration.

Higher decibels can be cut off using earplugs. More than that, safety shoes and other essential safety precautions should be applied to your workplace when you drill into concrete.

Anchor points and fall arrest systems should be in place to prevent workers from falling while working at height.

Regular maintenance and inspection of equipment and tools, along with proper training and supervision, are essential to ensure the safety of workers and the environment.

4. Use A Proper Concrete Drill Dust Removing Method

When you drill into concrete, you can see dust is spreading all over the space. Small silica particles will cause lung diseases and eye problems.

Although the user protects from the dust, it can affect to others due to its spreading. So let’s see what can you follow to reduce the drill dust.

- Use water – You can use water to reduce the drill dust. As well as it can control the heating of the drill bit and material

- Use dust collection tool – You can set up a dust collection instrument on the drilling point.

- Use vacuum – If you don’t have any, you can use a vacuum. It should be aimed to the drilling hole while you drill the hole

- More than that you can use these DIY tips to reduce or collect the drill dust.

- Use a paper bag

- Use a polythene bag

- Use a pre-drilled plastic plate

- Use dust trap

5. Drill the Pilot Hole for Accurate Concrete Drilling

When you drill into concrete, you should have a pilot hole for safe and efficient drilling. Concrete is a harder material. When drilling into concrete, you must place the drill bit in the exact place.

Due to the hardness, it can slip a bit. The pilot hole is very important when you drill an angle or use a hole cutter. As well as you have good confidence when you start with a pilot hole.

A pilot hole is more important for the overhead drillings. But it is useful for lower drilling also. Hammer drill bits are not sharp tools. Hence it will be slippery on the surface when it is rotating.

It is better to rotate first before activating the hammering action.

Normally pilot hole can be 1/2” – 1” in depth, and the diameter is 3/8” sufficient for the spiral drill bits.

6. Use Lower RPM and Activate Hammering Action for Concrete Drilling

Concrete is a hard material. When you drill it, you should use lower RPM and hammering action. Lower RPM produces higher torque and hammering action will crush the front material of the drill bit.

You can use below RPM and BPM for concrete drilling tasks for different types of drill bits.

- Fast Spiral Rotary: Rotary bits do not break the concrete. It can grind the concrete with thrust. Hence you can use a speed range from 450-700 RPM to 1/2″ diameter, 350-500 RPM from 5/8″ and up for effective drilling.

- Rotary/Percussion drill bits: Percussion drills are lightweight hammer drill. The drill bit is moved forward and backward with the chuck. Hence it can be used with a speed of 1300-3500 RPM at up to 50,000 blows per minute.

- Rotary Hammers: Rotary hammers are heavy-duty drills. SDS plus and SDS max drill bits are used on rotary hammers. Sometimes you can use a chisel for chipping the materials. Speed range 400-1000 RPM at up to 4500 blows per minute.

7. Use Water as Coolent for the Concrete Drilling

When you drill deep, drill bits will overheat due to the friction and rotation of the drill bit. In order to prevent this you can use water as a coolant. When you use water, it will reduce the spread of drill dust. But it is difficult to clean the hole if you use water as a coolant.

8. Clean the Drilled Hole in the Concrete After Drilling

After you have done the drilling, you should clean the hole and close it with a suitable cap to protect it from filling with debris. It is better to do the task as asap you drill it.

You can use a vacuum to clean the hole of dust and debris. If you have used the water, clean it with the water because when it dries, the inside will be solid due to the drilled dust.

Can You Drill Into Concrete Without a Hammer Drill?

You can’t drill into concrete without using a hammer drill because using a regular drill and drill bit for concrete will need more effort and time. In order to prevent this, you should use a hammer drill. Hammer drills consist of hammering action that helps crush the closer materials at the drill bit tip. Hammer drill bits are made of harder and tougher materials such as carbide, tungsten and vanadium. These materials withstand higher hammering force. Hence hammer drill and hammer drill bit increases the efficiency of the drilling.

Can You Use a Regular Drill Bit For Concrete Drilling?

No, you can’t use a regular drill bit for concrete. Regular drill bits are not harder and tougher like masonry drill bits. Using a regular drill bit on concrete will wear and overheat easily. Regular drill bits will not withstand higher hammering force.

How Long Should Concrete Cure Before Drilling?

Concrete should be allowed to cure for at least 36 hours before drilling. However, for the best results, it is often recommended to wait 7 days, which is the time it typically takes for concrete to reach its 65% of strength.

You should not drill into the concrete it the concrete is still soft, the drill can cause cracks and fractures, weakening the structure. It can also cause the hole to be misshapen or larger than intended. Furthermore, it can prevent the concrete from curing properly, which could lead to long-term structural issues.

What Size Drill Bit Need for 3/8 Anchor?

For a 3/8-inch anchor, you would typically need a 3/8-inch drill bit. The hole you drill should be the same diameter as the anchor you are using to ensure a tight fit. However, always check the manufacturer’s instructions as some types of anchors may require a slightly larger or smaller hole.

Can You Use the Same Drill Bit For Stone and Concrete?

Yes, you can use the same drill bit for both stone and concrete. Because both are harder and tougher materials. You should use a masonry drill bit (SDS Plus or SDS Max for the better performance to drill into the stone and concrete