When I needed to drill through the concrete column, I could drill a few inches in depth using a regular hammer drill, and then I met the inside rebar. So I had to stop and I had to use a rebar cutter. I had to change the drill bit and spent my time on that. When I use the SDS drill next time, I could drill the hole one time. So there are differences between SDS drills and Hammer drills. This is a complete guide with preparing all in detail about these tools.

What is the difference between SDS and hammer drill? SDS drills are types of hammer drills. Becuase of the piston-based hammering mechanisms and a special structured drill bit it can be used for heavy-duty drilling tasks such as concrete with rebars due to it high performance.

When you are going to buy an SDS drill, you can see there are 03 types with different. So do you know which one is suitable for you? Here I have included all in detail here. So keep reading on!

What is an SDS Drill?

SDS drill has been designed to provide more thrust to the drill bit. Chuck is not moving with the drill bit. The drill bit is mounted to the chuck with a special mechanism, and it can freely move forward and backward about 1 inch.

The inner hammerhead is powered by the piston. The piston is powered by another piston head, and compressed air is the medium for the piston movements.

The SDS drill is more powerful than hammer drills. There are special drill bits that are specially designed for the SDS hammer drills. If you buy an SDS hammer drill, you will need to buy the drill bits also. You can’t use the regular hammer drill bits in SDS drills.

More than the hammer drill mode, there is only a hammering mode that can be used. This hammering mode can use for the chisel for demolition purposes.

What is a Hammer Drill?

A hammer drill is a primary drilling tool that can be used on hard surfaces like concrete, brick, or stone. The hammer drill has a lower hammering action than SDS drills. This hammering action is named as percussion action of the hammer drill. The percussion rate is measured by the blows per minute (BPM). Normally a hammer percussion rate is more than 2,000. It helps to crush the material parts into small particles and remove them from the flutes of the drill bit.

But hammer drills can’t be used for drilling high-strength concrete due to the low power of the hammering action. Chuck is moving with the bit, and therefore there is no high-power hammering action in the tool.

What are the Differences Between Hammer Drill and SDS Drill

Usage Differences Between Hammer Drill and SDS Drill

Hammer drills are used for drilling wood, metal, concrete, stones, and bricks. A Hammer drill is used for drilling small depths and not through the reinforcement bars. So it is very suitable for DIY projects or household usage.

But if you are using the SDS hammer drill, this has changed overall different. SDS plus and SDS max are used for heavy-duty drilling such as concrete with reinforcements.

Chuck Differences Between Hammer Drill and SDS Drill

Hammer drill has a percussion mechanism with its chuck moving with the drill bit. A hammer drill chuck is with three Jaws, and when we tighten the chuck, these three jaws will move close, and the drill bit will tighten. Hammer drills do not need to provide much torque for the drilling there, for the chuck will not lose.

But SDS is with a different chuck. There is no key or rotational tighten. Just move backward the chuck and then put it into the chuck and move forward. It will be tight with inner bearings. The reason is SDS drill provides force directly to the drill bit. Therefore chuck does not move with the drill bit.

The drill bit can move about 1.5 inches forward and backward. Due to this back force effect is too much less.

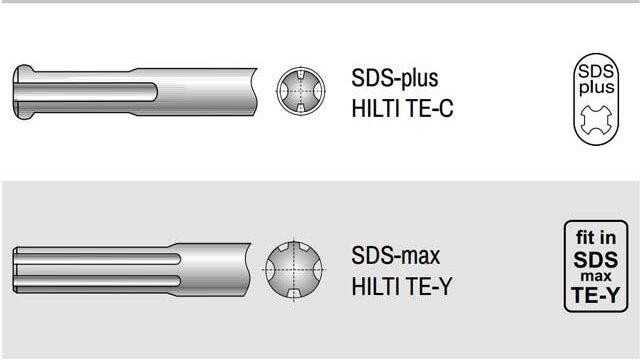

Considering the SDS and SDS max, there are different drill bits.

You can’t use the hammer drill bit on the SDS drill bit, and interchange uses each other.

Drill Bits Difference Between SDS Drill and Hammer Drill

Hammer drill bits are with a circular cross-section, and SDS plus drill bits are with the 4 rails, and SDS max is with 5 rails, and it is much longer than SDS plus drill bits. This will prove that SDS max piston action is longer than SDS plus.

SDS plus is a more common design, and it is used widely. But SDS max uses for special drilling purposes.

SDS plus drill bits can be pushed into the chuck. There is no tightening. SDS plus drill bits are about 10mm diameter, and SDS max is about 18mm diameter drill bits. SDS plus and SDS max drill bits are not able to interchange because of their various cross-section.

Hammer drill bits are with double parts (straight head cutter), and SDS drill bits are with quad parts (cross-head cutter). The end of the drill bit is made with a carbide tip. This can hold much temperature and resistance during the drilling.

SDS Plus and SDS Max can also use chisels for demolish the materials.

Read More About – Can I Use an SDS Drill Bit in Hammer Drill?

Performance Difference Between Hammer Drill and SDS Drill

Always, SDS hammer drills are powerful and high-performance.

Hammer drills have less hammering power due to the clutch percussion drilling. But the SDS hammer drill produces the hammering power by using the piston. Hence it is more powerful.

Normally, SDS hammer drills are 65% more efficient than regular hammer drills.

The drill bits are very strong to transfer the rotational force into the hammering and rotation. Due to this, the drill bits are powered with tungsten, titanium, and carbide metals. Those tools can hold heat and resistance.

Do you need Both SDS and Hammer Drills?

Yes, you need both SDS and regular hammer drills. Regular hammer drills are highly recommended for drilling concrete, brick, and stone up to limited depth. For the DIY projects, a regular hammer drill is enough. But for professional tasks, you should have an SDS hammer drill for the higher-performance tasks.