A drill bit is a cutting tool used in drilling machines to create cylindrical holes. A properly drilled hole should have correct diameter, perpendicular to the surface, absence of burrs, properly finished inside, and no tear out on the exit side of the hole. In order to have these qualities, you should choose a proper drill bit first.

A high-quality drill bit always consists of proper drill bit material, right coating, correct point angle, wide flute design, proper drill bit geometry, precise sizing, higher durability, heat resistance, higher cutting speed, sharpening capability, and a proper drill bit shank type.

What is the Quality of Drill Bit Materials?

Before choosing the quality drill bit for your task, you should know about the drill bit manufactured materials. The manufactured material significantly affects the drill bits’ performance, durability, heat resistance, wearing and tearing resistance, sharpness, cutting speed, and suitability for the task.

These are the most used 4 drill bits materials. These materials affect in various ways to the quality and the performance of the drill bit.

- High-Speed Steel (HSS) – HSS drill bits are made of mixing carbon and steel with different proportions. High-speed steel drill bits are hard, resistant to heat, and suitable for drilling into plastic, wood, and soft steels. HSS drill bits are generally cheaper than other types, making them popular for general use.

- Cobalt – Cobalt drill bits are extremely hard and heat-resistant. Cobalt drill bits are made of mixing cobalt and HSS. 5% cobalt included in HSS is named as M35, while 8% cobalt in HSS is classified as M42 drill bits. Cobalt drill bits have 65-70 HRC. Cobalt drill bits are ideal for drilling into stainless steel and other hard materials. They are more expensive than HSS bits, but their durability often makes them worth the investment.

- Diamond – Diamond drill bits are made of embedding the diamond powder into the metal. Diamond drill bits are used for very hard materials like glass, stone, and hardened steel. They offer the highest level of hardness and heat resistance.

- Tungsten Carbide – Tungsten carbide bits are extremely hard and durable. Tungsten carbide drill bits are ideal for heavy-duty tasks and drilling into hard materials. It has 70+ HRC hardness values. They maintain a sharp edge for longer periods. Hence it reduces the need for frequent replacements.

What is the Durable Drill Bit Coating?

Drill Bit coating is an external layer that is applied on the drill bit in order to increase the durability, reduce the wearing and tear resistance, friction and heat resistance between the workpiece. This increases the efficiency of the drilling hole and smooth cutting surface. The most used drill bit coatings are Black oxide, TiN, TiCN, TiAlN

- Black Oxide Coating – Black oxide is a thinner coat of magnetite (Fe3O4) layer around the HSS drill bits. Black oxide drill bit can improve the performance of HSS and reduce the friction between the drilling materials. Therefore it can be used on a wide range of materials such as steel, copper, wood, aluminum. After the black oxide is applied on the HSS drill bit its service life is increased by 50%.

- TiN Coating – A TiN drill bit is a type of Titanium coated drill bits. TiN is applied as a strong ceramic coating on the drill bit. It looks like a golden-colored drill bit. The TiN coating is extremely wear-resistant and has an approximate hardness of 80 to 85 HRC. Due to the TiN coating speed and feed can be improved by 40–60% and 10–20%, respectively.

- TiCN Coating – TiCN drill bit coating consists of Titanium, Carbon, and Nitrogen materials. Its thickness is 1-4 µm, and the hardness is 32GPa. It has a 0.5µ friction coefficient. Its color is blue and widely used in metal drilling tasks. It can withstand 400 °C of temperature.

- TiAlN Coating – TiAlN consists of Titanium, Aluminum, and Nitrogen. The TiAlN drill bits can be identified by the violet-coloured coating. TiAlN drill bits have a higher hardness of 85 HRC. Hence, those can be used to drill materials with hardness up to 67-70 HRC.

What is the Efficient Drill Bit Point Angle?

The drill bit point angle is the angle formed at the tip of the drill bit. Correct drill bit angle helps to drill holes with higher finish quality, increase drill bit life, improve drilling accuracy, reduce heat generation, lower the risk of drill bit breaking, optimize chip evacuation and lower energy consumption, and increase productivity. The cutting angle of the drill bit is varied with the material to be used. Below are the cutting angles of the drill bit for metal, wood, concrete, brick, tile, PVC, and fiber.

| Material | Drill Bit Angle |

|---|---|

| Mild Steel | 118° |

| High Tensile Steel | 130°- 135° |

| Stainless steel | 130°- 135° |

| Tough Steel | 130°- 140° |

| Sheet Steel | 130°- 135° |

| Aluminum | 118° |

| Bras, Bronze | 118° |

| Cast Iron | 118° |

| Plastic | 118° |

| Hard Rubber, Fiber | 60° |

| Soft Wood – Pine, Cedar, Rosewood etc | 118° |

| Hard Wood – Ash, Maple, Oak, Mahogany etc | 118° -135° |

| Concrete | 100° -115° |

| Brick | 100° -115° |

| Tile | 100° -115° |

| PVC | 50° -65° |

| Fibre | 50° -65° |

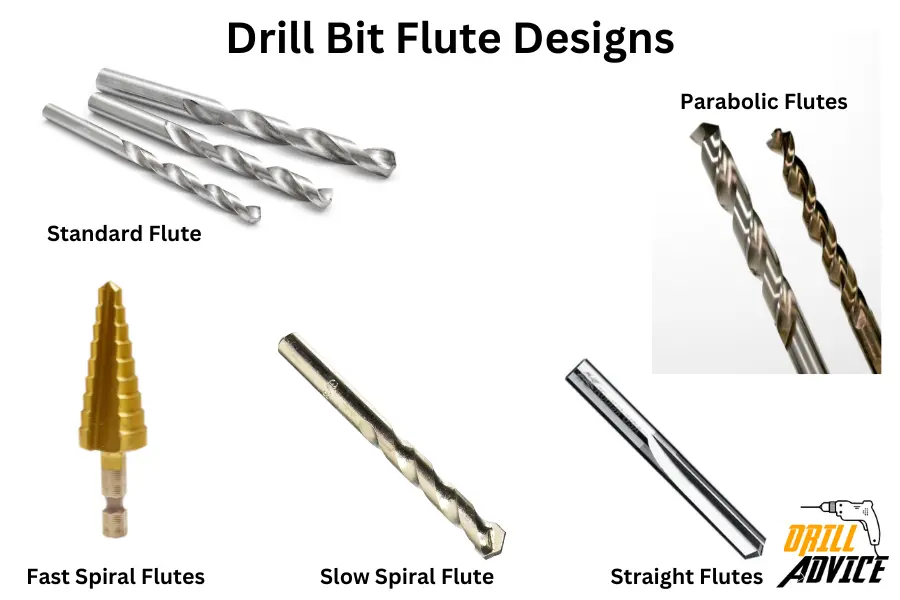

What are the Efficient Drill Bit Flute Designs?

A proper drill bit flute should be smooth and suitable to remove all the chips during the drilling. It helps to reduce friction reduce friction and prevents the cuttings from clogging up the hole, prevents the drill bit from overheating, drill precise and smooth clean holes, reduces the heat and improves the drill bit performance and maintain the drilling stability without wobbling or clogging inside the hole.

These are the 5 main drill bits flutes and their usage

- Standard flute – Standard flutes are designed for general-purpose drilling in a variety of materials such as wood, plastic, and metal

- Parabolic flutes – Parabolic flutes are suitable for deep-hole drilling applications or drilling in long-chipping materials.

- Fast spiral flutes – Fast spiral flutes are typically used for drilling in softer materials such as aluminum. Their aggressive design helps in faster chip removal.

- Slow spiral flute – Slow spiral flutes are designed for drilling harder materials. They are less aggressive in chip removal, and the strength of the bit is enhanced.

- Straight flutes – They are used for drilling in harder, more brittle materials such as glass or ceramics.

What is the Suitable Drill Bit Geometry?

Drill bit geometry is the shape of the drill bit. It helps to drill efficiently into the material with minimum effort. The drill bit geometry is varied with the used material such as wood, metal, masonry, and tiles. These are the most used drill bit geometries.

Wood drill bit types

- Gimlet drill bit

- Brad point drill bit

- Hinge sinker drill bit

- Spade drill bits

- Forstner drill bits

- Spoon drillbits

- Auger drill bits

- Count sink drill bit

- Wood hole saw

- Step drill bit

These wood drill bits can be used for both softwood and hardwood.

Metal drill bit types

- Lefthand drill bit

- Spotting hole drill bit

- Metal hole saw

- Gun drill bit

- Ejector drill bit

- Counter sink drill bit

- Center drill bit

- Step drill bit

These metal drill bits are used for the different tasks in metal drilling.

Masonry drill bit types

- SDS drill bits

- SDS Max drill bits

- Chisel bits

- Diamond drill bits

In order to have maximum efficient masonry drill bits such as chisel bit, SDS Plus and SDS Max should be used with a SDS Max drill.

What are the Available Drill Bit Sizes?

Before you buy a quality drill bit you should pay attention to the drill bit sizes, dimensions and units. Drill bits are available in different sizes and geometries for the various materials. When you choose a drill bit, you should know its length and diameter.

- Drill bit size is considered to be the drill bit diameter and drill bit length.

- Drill bit size is measured by the numerical values as well as a number gauge.

- Drill bit size is measured by numerical values using the inches (in) and millimeters (mm). One inch equals 25.4 millimeters (1 inch = 24 millimeters). Using this, you can convert unit conversion between drill bit sizes.

- Drill bit number gauges run from size 1 to 80 (with 1 being the largest and 80 the smallest). Letter gauges run from sizes A to Z.

- The standard diameter of the drill bits is varied from 1/16 inch (1.57mm) to 3.5 inch (90mm)

- The standard drill bit length can be varied from 3.5 inches (90mm) to 24 inches (609mm)

What is the Durability of the Drill Bit?

Before you buy a drill bit, you should know its durability. A quality drill bit is more durable than a low-quality drill bit. The durability of the drill bit mainly depends on these main 4 factors such as drill bit material, coating, usage, and the material to be used to drill.

- Drill bit material – Drill bit material is the core material of the drill bit, while coating is the outer material. Drill bit materials like cobalt, carbide, diamond, and tungsten carbide have a higher HRC value. Hence these bits are prolonged than regular HSS drill bits.

- Drill bit coating – Drill bit coating reduces the friction between the drill bit and the workpiece surface. This reduces the friction between the workpiece and the drill bit while it is rotating. The most used drill bit coatings are Black oxide, TiCN, TiAlN and TiN.

- Drill bit usage – The way of drill bit usage directly affects the durability of the drill bit. For a durable drill bit you should use a sharpened drill bit with the recommended RPM and feeding rate. In order to reduce the drill bit heating you can use a coolant while you drill metals. You can use water as a coolant when you use a masonry drill bit. You should not push too hard on the drill that causes to overheat the drill and drill bit during drilling.

- Used material – Drill bits are specially designed for specific materials. When you choose a quality drill bit you should be aware the versatility of the drill bit. The versatility of the drill bit depends on the drill bit material and coating. Hence you should choose a proper drill bit that can be used on a wide range.

What is the Heat Resistance of the Drill Bit?

Before you buy a drill bit you should know the heat resistance of the drill bit. Heat resistance is the process of heat dissipating from the drill bit. This depends on the material, coating, coolant, and the type of the work.

- Heat-resistant drill bit materials – Excellent heat-resistant materials are Tungsten carbide, carbide and cobalt. HSS is the lowest heat-resistant drill bit material

- Heat-resistant drill bit coating – Drill bit coatings are used to dissipate the heat properly. The most used drill bit coating are Black oxide, TiN, TiCN and TiAlN.

How to Sharpen a Drill Bit?

When you choose a drill bit, you should know about the capability of the drill bit sharpening. Drill bit sharpening is the process of renewing the edges of a drill bit to maintain its effectiveness. When a drill bit is used over time, its cutting edge becomes dull. That can result in poor performance, slower drilling speed, and the need for more force and time to drill through materials.

In order to prevent this, you should sharpen the drill bit. You can sharpen all of the wood drill bits using a regular sharpener like a bench grinder. But you can’t sharpen all of the metal and masonry drill bits.

You can sharpen HSS and cobalt drill bits using a bench grinder. But you can’t sharpen tungton carbide, carbide drill bits using a regular bench grinder. These materials are hard and tough; hence you will need a diamond sharpening tool.

You should not sharpen the coated drill bits. When you sharpen a coated drill bit, the coating can be worn. As a result, this coated drill bit acts as a non-coated drill bit. Hence, you should not sharpen the coated drill bit at any time.

What are the Drill Bit Shank Types?

A drill bit shank is the end part of a drill bit that is gripped by the drill chuck. It helps to transfer the torque from the drill to the drill bit in order to do the actual drilling. The shank can come in various shapes, including straight, hexagonal or the most common type, the SDS shank, each designed to fit into different types of drill chuck.

- Straight shank – A straight shank is the most commonly used shank in the construction industry. It allows the bit to be held securely in place, providing faster setup and easy change out between bits.

- Hex shank – This shank creates an even stronger hold for drill bits, particularly those used for heavy-duty work such as masonry and construction. This prevents the bit from slipping inside the chuck.

- SDS (Slotted Drive System) shank – This is typically used for heavy-duty work such as demolition and concrete drilling. SDS shanks are designed for hammer drills.

- Triangle shank – These shanks are used for drilling into glass and tile to prevent the bit from slipping.

- Tapered shank – They are more commonly used in a drill press rather than a handheld drill. It provides a very secure fit between the shank and chuck. It’s common to use this type with larger bits.

- Morse taper shank – This type of shank is used for industrial purposes on machinery like drill presses and lathes.

- Quick-release or locking bit holders – Designed for quick change and release of bits. The design includes features like springs and bearings to provide support to the bit.

What is the Drill Bit Cutting Speed?

Drill bit cutting speed, also known as cutting velocity, is the speed difference between the cutting tool and the surface of the workpiece it is cutting. It is often measured in meters per minute (m/min) or feet per minute (ft/min).

The calculation of the optimal cutting speed depends on the kind of material being drilled and the characteristics of the drill bit (such as its diameter and material). Faster cutting speeds can lead to faster drilling but may also result in increased wear on the drill bit.