The M35 cobalt drill bit includes 5% cobalt, and the M42 cobalt drill bit includes 8% of cobalt. Cobalt is mixed with High-Speed Steel (HSS). Due to the different cobalt mixing, both have different physical characteristics. M42 is stronger and has more thermal resistance than M35. The M42 drill bit has a higher status of sharpening and more durability.

Hence M42 drill bits can be used in a wide range of tough metals continuously with higher RPM. Due to these characteristics, M42 drill bits are more expensive and suitable for factory usage. M35 drill bits can be used for cost-effective general-purpose drilling tasks.

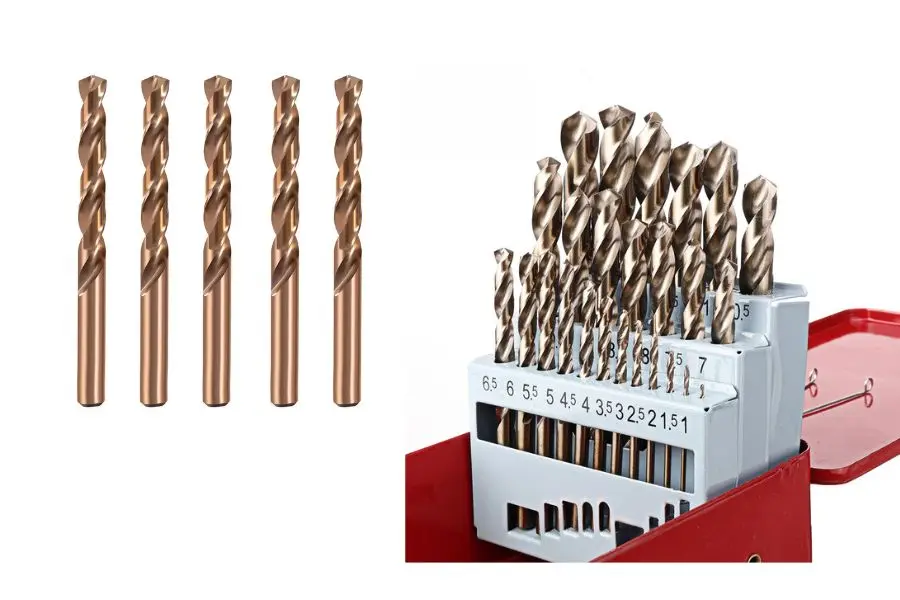

What Is M 35 Drill Bit?

M35 is a type of cobalt drill bit with mixing of 5% of cobalt and HSS. M35 Cobalt drill bit has a hardness of 65-67 HRC and a higher melting point of 2723 oF. Hence, M35 Cobalt drill bits are more heat resistant. Therefore, M35 cobalt drill bits are used to drill many hard materials. Due to the 5% cobalt, its physical properties and chemical properties are varied. Hence it can be used in a wide range than a regular drill bit.

What Is M 42 Drill Bit?

M35 is a type of cobalt drill bit with mixing of 8% of cobalt and HSS. M42 cobalt drill bit has a hardness of 68-70 HRC and a higher melting point of 2853 oF. Due to the 8% of cobalt, M42 is harder and more stable. Hence it can withstand higher temperatures and thrust successfully.

M42 drill bits are used in wide range than M35 drill bits. Both M35 and M42 cobalt drill bits are good for metal drilling.

What are the Differences Between M35 Vs. M42 Drill Bits?

The main differences between M35 and M42 drill bits can be compared with cobalt percentage, melting point, heat resistance, sharpening status, durability, and the cost of the drill bit.

| Properties | M35 Drill Bit | M42 Drill Bit |

|---|---|---|

| Percentage of Cobalt | 5% | 8% |

| Melting Point (oF) | 2723 | 2853 |

| Resistant to heat | Resistant to heat but less than M42 drill bits. | Higher resistance to heat |

| Status of sharpening | Enough sharp to drill a hole in any metal. | Sharper than M35 drill bits. |

| Durability | Sharp Enough to drill a hole in any metal. | Less than M35 drill bits because of consisting of more percentage of Cobalt. |

| Cost | Little cheaper than the M42 | Expensive |

What Is Better, M35 or M42 Drill Bit?

Among M35 and M42 cobalt drill bits, M35 drill bits are suitable for drilling into materials like stainless steel, alloy steel, and other tough metals. M42 drill bits are especially well-suited for drilling into very hard and abrasive materials, including superalloys, cast iron, and high-strength steel.

M35 cobalt drill bits are more affordable than M42 drill bits, making them a cost-effective choice for general-purpose drilling tasks. In demanding applications, M42 cobalt drill bits last longer and maintain their sharpness better than M35 bits.