Aluminum is a lightweight chemical element with the symbol of Al and the atomic number of 13. Aluminum was discovered in 1825 by Hans Christian Ørsted. Aluminium is extracted from the bauxite rock using the Bayer and Hall–Héroult processes. Aluminium is the second most used metal in the world. The aluminium consumption is 88 million tonnes per year. China is the biggest aluminium producer in the world, and Alcoa Corporation is the largest US aluminium producer.

Aluminum has both chemical and physical properties. The most important chemical properties is corrosion resistance and the physical properties are density, tensile strength, weight and strength-to-weight ratio. Due to the lightweight and higher strength, aluminium is mostly used in the aerospace, medical, and construction industries.

Aluminium is different types such as aluminium 1100, 2024, 3003, 5052, 6061, and 7075. Each type has a primary alloy element. Each type has a different strength, density and physical and chemical properties. Pure aluminium has a tensile strength of 276 MPa. Different types of aluminium has various strength. Working with aluminium is easy due to its low density and lightweight. Cutting, drilling, bending, forming, welding and finishing are important activities in aluminium working.

A small aluminium amount is not toxic for the human. But a large amount of aluminium can affect the brain, lungs, blood and digestive system badly. Using a face mask will protect the chronic effect of the aluminium.

What are the Chemical Properties of Aluminum?

Chemical properties are characteristics that become evident during a chemical reaction, altering the substance’s molecular composition. These properties are essential because they determine how substances interact with each other and the changes they undergo under different conditions.

The chemical properties of Aluminum is important for safe handling and optimal use. As an example, chemical properties will help you to know how aluminum reacts with certain substances and can guide you on how to store and clean aluminium tools.

Let’s look at some of the key chemical properties of aluminium:

| Chemical Properties | Description |

|---|---|

| Reactivity | Aluminum is highly reactive but is normally protected by a layer of oxide. |

| Corrosion Resistance | When exposed to air, aluminum forms a hard protective oxide layer, providing excellent corrosion resistance. |

| Affinity for Oxygen | Aluminum has a high affinity for oxygen, making it a useful reducing agent in the extraction of other metals. |

| Flammability | Aluminum powder can be flammable or explosive, but solid aluminum is not. |

| Effect of Acids | Aluminum reacts with most acids to produce hydrogen gas. |

| Reaction with Alkalis | Aluminum can react with alkalis to form aluminates. |

What are the Physical Properties of Aluminum?

Physical properties are characteristics that can be observed or measured without changing the substance’s identity. The most helpful physical properties are color, density, melting point, boiling point, specific gravity, electric conductivity, and hardness.

The physical properties of aluminum is important because they directly influence its usability in various DIY and home improvement applications. They can dictate how to cut, shape, and even heat treat aluminum equipment or furniture.

Here are the notable physical properties of aluminum:

| Physical Properties | Value |

|---|---|

| Appearance | Aluminum is silvery-white and shiny. |

| Density | 2.7 g/cm³, (aluminum is lightweight) |

| Malleability | Aluminum is malleable, meaning it can be hammered or rolled into thin sheets. |

| Ductility | Aluminum is ductile and can be drawn into thin wires. |

| Conductivity | Aluminum is a good conductor of heat and electricity. |

| Melting Point | 933.47 K (660.32 °C, 1220.58 °F) |

| Boiling Point | 2743 K (2470 °C, 4478 °F) |

| Elastic Modulus (Young’s Modulus) | 70 GPa |

| Specific Heat | 0.897 J/g°C, |

| Hardness | Mohs hardness – 2.75 Vickers hardness – 160–350 MPa Brinell hardness – 160–550 MPa |

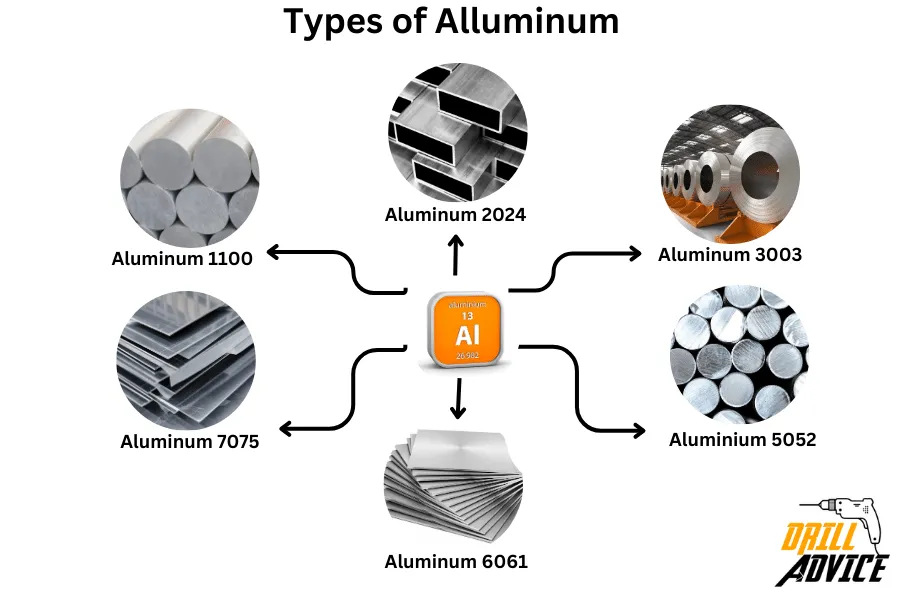

What are the Types of Aluminum And Usage?

Aluminum, a lightweight and versatile metal, has a wide array of types. Each type of aluminum possesses unique characteristics due to differing alloying elements, providing distinct strengths, ductility, and applications. Let’s explore some common types of aluminum:

1. Aluminum 1100

- Primary Alloying Element: Essentially pure aluminum (99.0–99.95%), with a small amount of copper (0.05–0.20%) for strength.

- Commercial Name: Commercially Pure Aluminum

- Category: Non-heat-treatable

- Strength and Ductility: Aluminum 1100 is soft and ductile, with lower strength. However, its ductility makes it highly formable.

- Usages: Its excellent resistance to corrosion and superior workability make it ideal for applications like food and chemical equipment, roofing, and siding.

2. Aluminum 2024

- Primary Alloying Element: Copper (3.8–4.9%)

- Commercial Name: Aluminum-Copper

- Category: Heat-treatable

- Strength and Ductility: Known for high strength and good fatigue resistance, but it’s less ductile.

- Usages: Owing to its strength, Aluminum 2024 is widely used in aerospace applications, bolts, gears, and shafts.

3. Aluminum 3003

- Primary Alloying Element: Manganese (1.0 to 1.5%), Aluminum (96.8–99%)

- Commercial Name: Aluminum-Manganese

- Category: Non-heat-treatable

- Strength and Ductility: Moderate strength, excellent ductility.

- Usages: Aluminum 3003 is typically used in mailboxes, cabinets, tanks, stampings, spun and drawn parts, and fan blades.

4. Aluminum 5052

- Primary Alloying Element: Magnesium (2.2%-2.8% by weight)

- Commercial Name: Aluminum-Magnesium

- Category: Non-heat-treatable

- Strength and Ductility: High strength compared to other non-heat-treatable alloys, good ductility.

- Usages: This type finds use in marine applications, home appliances, fuel tanks, and other applications where good formability and corrosion resistance are essential.

5. Aluminum 6061

- Primary Alloying Element: Magnesium (0.8%-1.2% by weight) and Silicon (0.4%-0.8% by weight)

- Commercial Name: Aluminum-Magnesium-Silicon

- Category: Heat-treatable

- Strength and Ductility: Offers a balance of high tensile strength with good formability.

- Usages: Due to its versatility, Aluminum 6061 is used in many structural and fabrication projects, from bicycle frames to aircraft wings.

6. Aluminum 7075

- Primary Alloying Element: Zinc (5.6%-6.1% by weight)

- Commercial Name: Aluminum-Zinc

- Category: Heat-treatable

- Strength and Ductility: Among the highest-strength aluminum alloys with fair ductility.

- Usages: This type is frequently used in aircraft fittings, gears and shafts, missile parts, and other high-stress applications.

What are the Strength of Aluminum Types?

The strength of the metal is measured by the tensile strength and ultimate tensile strength. Tensile strength is the maximum stress a material can withstand while being stretched or pulled before breaking. It’s a fundamental factor for engineers and DIY enthusiasts when choosing materials for specific applications.

Ultimate Tensile Strength (UTS). The UTS is the highest stress point on the engineering stress-strain curve, indicating the maximum stress a material can withstand while being stretched or pulled before necking – where the material cross-section starts to contract significantly.

The UTS is particularly crucial as it provides a definitive threshold for mechanical stress. Crossing the UTS could lead to catastrophic failure in the structural integrity of a material, causing safety and durability concerns. For applications under considerable tensile stress, UTS is a definitive guide to material choice.

| Types of Aluminum | Ultimate Tensile Strength |

|---|---|

| Aluminum 1100 | 90 – 120 MPa |

| Aluminum 2024 | 325 – 470 MPa |

| Aluminum 3003 | 130 – 300 MPa |

| Aluminum 5052 | 210 – 290 MPa |

| Aluminum 6061 | 260 – 310 MPa |

| Aluminum 7075 | 470 – 570 MPa |

What are the Aluminum Works?

The major aluminum works are cutting, drilling, bending, forming, and welding. After these activities, aluminum should be cleaning and finishing with relevant coatings. Non ferrous saw baldes should be used in aluminum cutting with 3000rpm. HSS, cobalt drill bit should be used to drill the aluminum with 18000 SFM. Bending and forming should be done carefully. Using a TIG welder, aluminum can be welded properly. Suitable coatings should be applied after the cleaning it. In order to prevent the galvanic corrosion don’t use with electrolyte metals.

- Aluminum Cutting: The cutting method is varied with the thickness of the metal piece. Aluminum sheets can be cut using tin snipes. Thicker aluminum pieces can be cut using jigsaw or bandsaw. Other types of aluminum can be cutting using a non-ferrous metal cutting blade. You can keep 3000 rpm as the speed of the blade if you are using a standard, high-speed aluminum circular saw. When you saw aluminum, make sure that the blade is sharp and moves at the right speed to avoid tearing or gumming up.

- Aluminum Drilling: The most standard drill bits can be used to drill aluminum. When you drill use sharp bit and lower speed to prevent overheating. You can use 18000 SFM as the cutting speed of the aluminum. You can prevent overheating and improve the heat dissipate if you use cutting oil.

- Aluminum Bending and Forming: One of the great things about aluminum is its malleability. It can be bent and formed into a variety of shapes. For simple bends, a metal brake can be used. For more complex shapes, a process known as deep drawing might be used.

- Aluminum Welding: Welding aluminum is more challenging than welding steel and requires specialized equipment like a TIG (Tungsten Inert Gas) welder and skills to handle aluminium’s higher thermal conductivity and lower melting point (1220.54 degrees Fahrenheit).

- Aluminum Finishing: Aluminum can be left as-is after cutting and shaping, but it can also be polished, painted, or anodized for a more finished look or for added protection against corrosion.

- Aluminum Cleaning: Aluminum can be cleaned with warm water and a mild detergent. For tougher stains or oxidation, a specialized aluminum cleaner may be needed.

- Avoiding Galvanic Corrosion: If you’re combining aluminium with other metals in your project, be aware of galvanic corrosion, which can occur when dissimilar metals are in contact in the presence of an electrolyte.

Is Aluminum Toxic Metal?

Aluminum is not a toxic metal. The human body can tolerate and eliminate small amounts of aluminum through natural processes such as drinking water and food. But large quantities can lead to toxicity and adverse health effects. It is important to note that most people are not exposed to harmful levels of aluminum in their daily activites.

Aluminum can accumulate in certain tissues and the brain due to chronic exposure. As a result of this, humans can affect neurological disorderes like Alzheimer disease.

Read More About – High-Speed Steel: Properties, Types, Grades and Usage

What are the Symptoms of Aluminum Toxicity?

High levels of aluminum can affect the human body. These are the 5 heavier symptoms of aluminum toxicity. These symptoms can be varied with the amount of exposure and duration of the exposure.

- Gastrointestinal issues – Digestive problems

- Respiratory problems – Coughing and shortness of breath

- Neurological symptoms – Memory loss, confusion, cognitive impairment, and problems with coordination and balance.

- Anemia – Deficiency of red blood cells or hemoglobin in the blood.

- Bone and muscle pain – Calcium metabolism potentially leads to bone pain and muscle weakness.