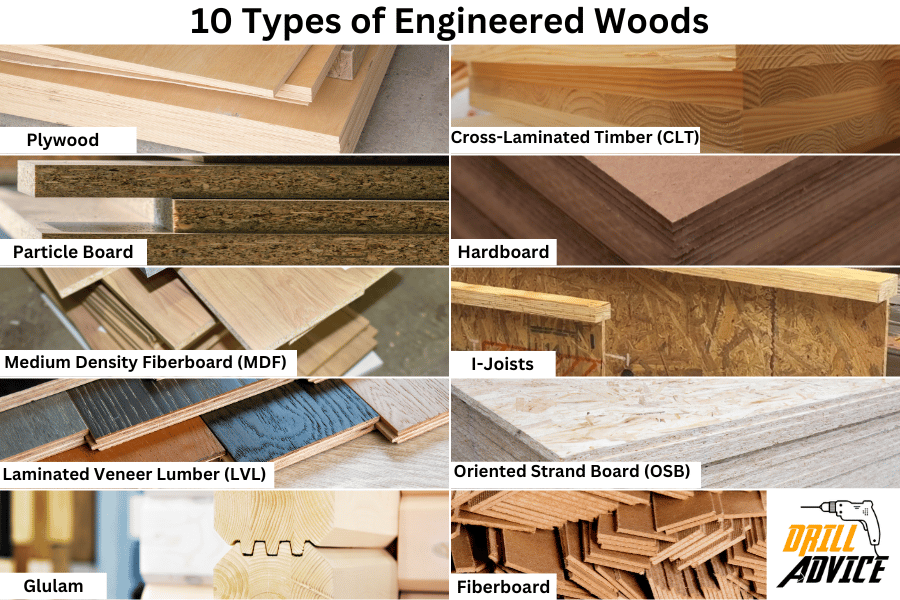

Engineered wood can be defined as the category of wood products that are manufactured by binding strands, particles, fibers, or veneers of wood, together with adhesives to form composite materials. Engineered wood has been designed for an affordable price, including improved strength, high workability, and less maintenance and repair compared to traditional solid wood.

The most popular 10 types of engineered woods are plywood, particle board, medium density fibre board (MDF), laminated veneer lumber (LVL), hardboard, I-Joists, Oriented strand board (OSB), and fiberboard

Engineered woods price is varied with the thickness of the wood type. When the thickness is higher, it needs more adhesives and layers. Therefore manufacturing cost is increased. As result of this, engineered wood price is increased with the layer thickness.

Engineered wood strength is increased with the grain directions, adhesive type, and layer thickness. When the wood strength is increased it is resistant to bending and warping. Engineered wood consists of wood layers and adhesives. Therefore workability is easier than solid wood. Engineered wood occurs with fewer splintering and chips. The final finishing of the engineered wood is higher than solid wood, but it is not quality as the solid wood.

Engineered woods are highly sensitive to water and wetness. If the wood type gets wet it tends to swelling and warping. When the engineered wood is fully open to the water, layers can be separated easily. Therefore engineered wood should be protected from water and moisture every time. Each and every engineered wood type has pros and cons.

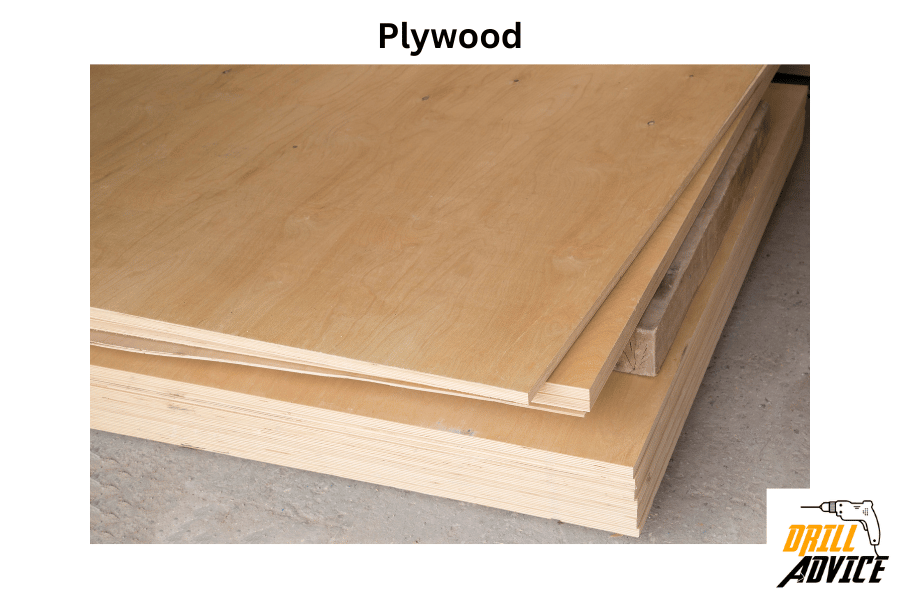

Plywood

Price: Plywood is a cost-effective than solid wood. The square feet of plywood is around $0.4 – $2.7. Lower-grade plywood types are cheaper and higher-quality plywoods are expensive, like marine or hardwood plywood types.

Strength: The strength of the plywood is varied with the plywood board thickness. Thicker plywoods have more layers. These layers have grains that run in vertical and horizontal directions. This cross-graining pattern improves its strength. It resists warping and bending better than solid wood.

Workability: Working with plywood is relatively easy when compared to solid wood. Plywood can cut smoothly, but finishing is not quality as much in standard plywood. But higher-grade plywood has a higher finish quality.

Maintenance and Care: Plywood requires more repair and maintenance than solid wood because of its layers. Air, water, dust, and mist can weaken the glue between layers. Therefore keep the plywood dry and clean to ensure its longevity.

Advantages:

- Cost-effective: Plywood is more affordable than many solid woods.

- Versatile: Plywood is suitable for a wide range of projects.

- Consistency: Plywood has fewer knots and imperfections than solid wood.

- Stability: Plywood is resist for warping and shrinking.

- Layered Design: Plywood layers can improve the strength.

Disadvantages:

- Vulnerability: Plywood is delaminating in wet conditions.

- Less Appearance: Lower-grade plywood might look less attractive.

- More Weight: Plywood can be heavier than some solid woods.

- Limited Lifespan: Plywood doesn’t last as long as some solid woods if not maintained.

- Rough Edges: Exposed edges can look rough and may need finishing.

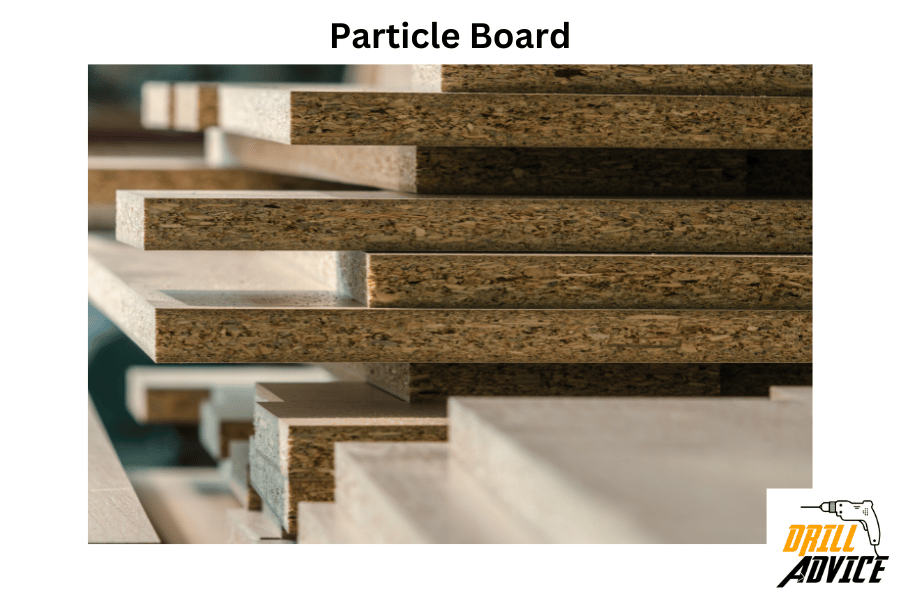

Particle Board

Price: Particle board is budget-friendly engineered wood material. Particle board costs around $0.5 – $1.5. Particles board has a low price considering the plywood. Because it’s made from wood waste like sawdust. However, there are pricier plywood options available, which are more refined.

Strength: The particle board has moderate strength. It doesn’t have grain patterns like solid wood. Instead, it’s composed of compressed wood particles. These give it uniform strength. However, it’s not as strong as plywood or solid wood.

Workability: Working with particle board is easier than solid wood. It’s softer than solid wood, so cutting and finishing is easy. But edges can be chipped without splinterings. The finishing surface of the particle board can look smooth, especially with veneer or laminate on top.

Maintenance and Care: Particle boards need regular care and maintenance but it is less than solid wood. Particleboards are sensitive to water, and dust. Water can swell the particle board. Dust can degrade the particle board surface over time. Therefore particle boards should be protected and keep cleaning from moisture well.

Advantages:

- Affordable: Particle boards are often cheaper than other wood types.

- Uniformity: Particle boards have no grain. Therefor it has a consistent look.

- Easy to Work With: Particle boards are good for beginners due to its softness.

- Versatile: Particle boards are great for many indoor projects.

- Adaptable Finish: Particle boards can be veneered or laminated for a polished look.

Disadvantages:

- Moisture Sensitive: Particle boards can warp or swell if it is wet.

- Less Durable: Particle boards are not as strong as other wood types.

- Can Chip: Particle board edges and surfaces are prone to chipping.

- Limited Lifespan: Particle boards are heavy and usable, it wears out faster.

- Not for Load-bearing: Particle boards are not suitable for weight-bearing projects.

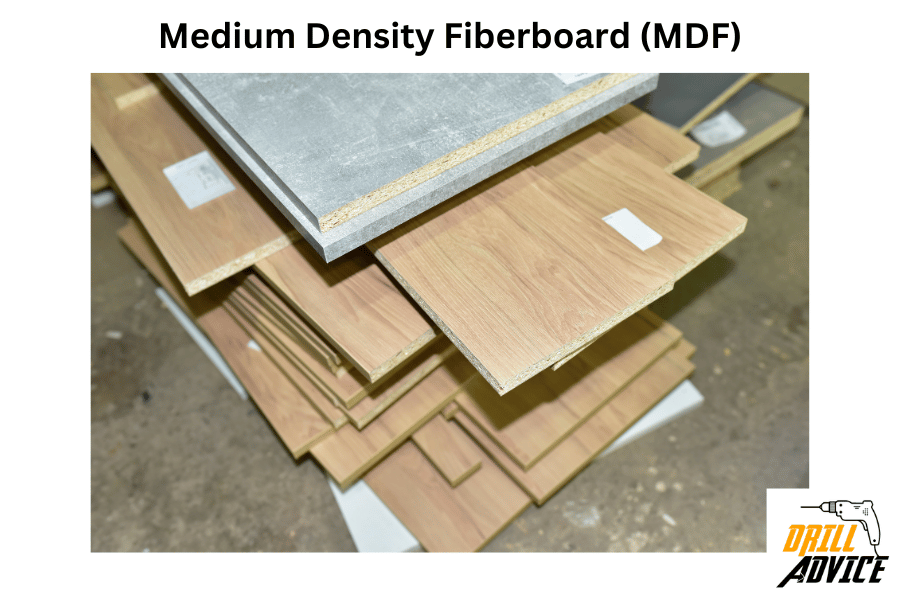

Medium Density Fiberboard (MDF)

Price: MDF has an affordable price. Medium density board cost is low because it uses wood fibres and resin. But moisture-resistant medium-density boards are more expensive than standard boards.

Strength: MDF boards have a consistent strength, but they don’t have a grain pattern like solid wood, it doesn’t have grain patterns. Instead of the grain patterns, wood fibres mix with glue and pressed into sheets. This process results in uniform strength. It’s sturdy but not as tough as some plywood.

Workability: Handling MDF is straightforward compared to solid wood. MDF is easier to cut without splintering. This uniformity gives a smooth finish. Paint and veneers adhere well on the MDF surface. Therefore MDF can give a polished look.

Maintenance and Care: MDF needs more repairs and maintenance than solid wood. Because MDF can be damaged by water easily. As well as air and dust might dull the MDF finish. Therefore MDF should be sealed properly to protect the MDF.

Advantages:

- Cost-friendly: MDF is often less expensive than many wood alternatives.

- Smooth Surface: MDF is perfect for painting or veneering.

- Consistency: MDF has no knots or grain to work around.

- Flexibility: MDF can be shaped into intricate designs.

- Size Variety: MDF are available in various thicknesses for different needs.

Disadvantages:

- High Moisture Sensitivity: MDF can bulge or warp when wet.

- More Weight: MDF are heavier than some plywoods.

- Less Durability: MDF can dent or scratch more easily than solid wood.

- Off-gassing: Some MDFs release formaldehyde over time.

- Not for Heavy Loads: MDF are best for decorative, not structural, projects.

Laminated Veneer Lumber (LVL)

Price: A linear foot of laminated veneer lumber will cost around $9 -$18. But its price will be varied with the thickness of the LVL. LVL costs more than some solid woods due to its manufacturing process.

Strength: Laminated veneer lumber has a higher strength. LVL layers of wood veneers stack together with their grains parallel. This structure makes a single square foot of LVL strong and reliable. The grain pattern of LVL helps improve this strength, making it superior to many woods.

Workability: Laminated veneer lumber doesn’t warp or twist compared to solid wood. It can handle heavy loads and spans large areas without support. The finishing quality is smooth and consistent. Therefore LVL can be used for many applications.

Maintenance and Care: Laminated veneer lumber needs minimal repairs. It resists environmental stresses better than solid wood. LVL can protect it from excessive moisture. When you use it outdoors you should check it regularly.

Advantages:

- Super Strong: LVL handles heavy loads with ease.

- More Stable: LVL doesn’t twist or warp like some woods.

- More versatile: LVL is suitable for various applications, both indoor and outdoor.

- Long Spans: LVL is great for beams as it spans long distances without much support.

- Uniform: LVL has consistent strength and appearance throughout.

Disadvantages:

- Price: LVL are more costly than traditional lumber.

- Weight: LVL are heavier, making handling a bit challenging.

- Need Specialized Tools: LVL needs specialized tools.

- Limited Aesthetic Appeal: LVL doesn’t offer the natural wood look.

- Less Eco-friendly: Production can have more environmental impact than natural wood.

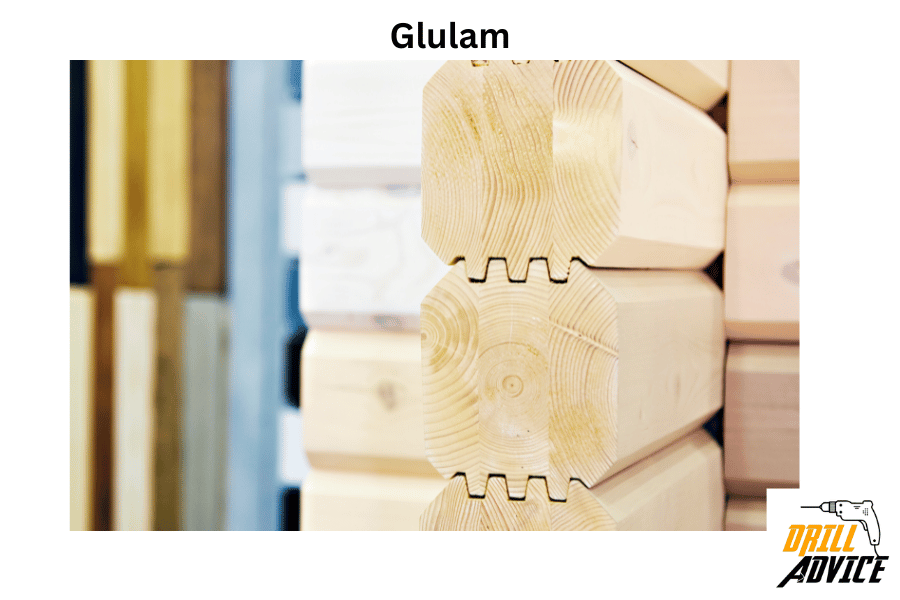

Glulam

Price: Glulam stands for “glued laminated timber.” The linear foot of the glulam will cost around $5-$35. Glulam isn’t always cheap. It often costs less than steel but more than some woods like certain cross-laminated timbers.

Strength: Glulam has glued layers. These layers are glued and crisscrossed. Therefore glulam is a stronger engineered wood. Therefore many builders trust glulam for heavy-duty tasks.

Workability: Glulam is more stable than solid wood. It won’t twist or bend easily. Glulam can shape, cut, and finish smoothly. This flexibility helps woodworkers achieve their design easily with stability.

Maintenance and Care: Glulam beams can last long with proper care and maintenance. Glulam should be shielded from wetness because moisture can weaken the glue over time.

Advantages:

- Higher Strength: Glulam is perfect for heavy jobs.

- Design Flexibility: Glulam can be curved or straight.

- Consistency: Glulam is uniform and reliable in performance.

- Long Spans: Glulam is ideal for big spaces without many supports.

- Weather Resistance: Glulam has a small weather resistance.

Disadvantages:

- Higher Cost: Glulam can be more expensive than some woods.

- More Weight: Glulam is heavy. Therefore need equipment or help to move.

- Special Fasteners: You might need unique hardware.

- Fewer Appearance: Lacks the natural look of traditional timber.

- High Moisture Sensitive: The glue might degrade if constantly wet.

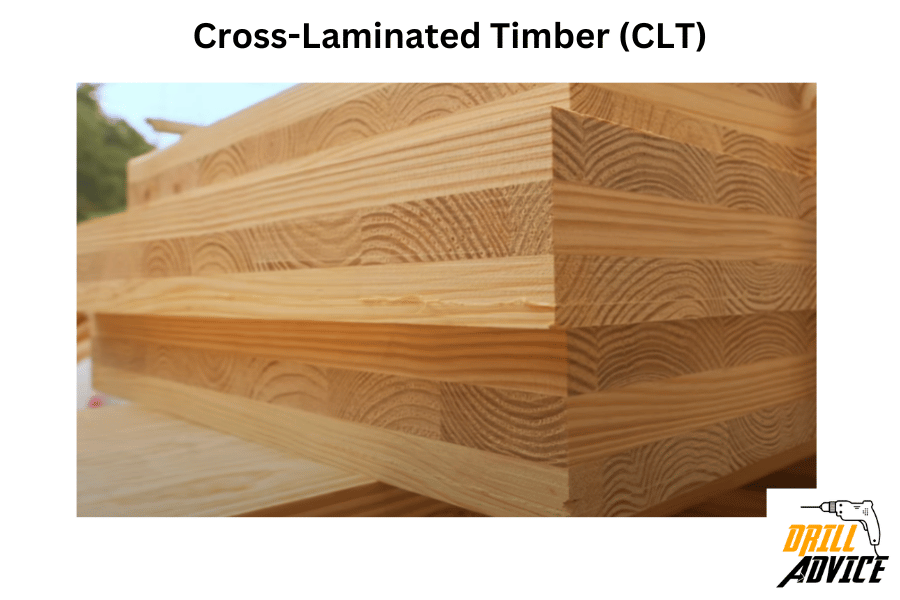

Cross-Laminated Timber (CLT)

Price: CLT means “Cross-Laminated Timber.” A square foot of cross laminated timber will cost around $30 – $50. CLT is not a cheap wood.

Strength: CLT has a different direction grain. Therefore CLT is stronger and perform well under pressure.

Workability: CLT is a stable engineered wood type. It is not twisting or warping like some woods. You can cut, shape, and finish it smoothly. Compared to solid wood, it’s consistent. That means fewer surprises and a great finsihing look.

Maintenance and Care: CLT needs fewer repairs and maintenance. CLT should protect from getting too wet. Water can harm CLT layers when it is open to water.

Advantages:

- Higher Strength: CLT are great for big projects.

- Uniformity: CLT is consistent, making work easier.

- Versatile: CLT can be used for floors, walls, or even roofs.

- Fire Resistant: CLT have long fire-resistant duration than some woods.

Disadvantages:

- More Weight: CLT is too heavy.

- Expensive: CLT are more expensive than basic plywood.

- Special Tools: CLT needs certain tools to work it.

- Size Limits: Comes in preset sizes.

- Moisture Concern: Layers can delaminate if wet too long.

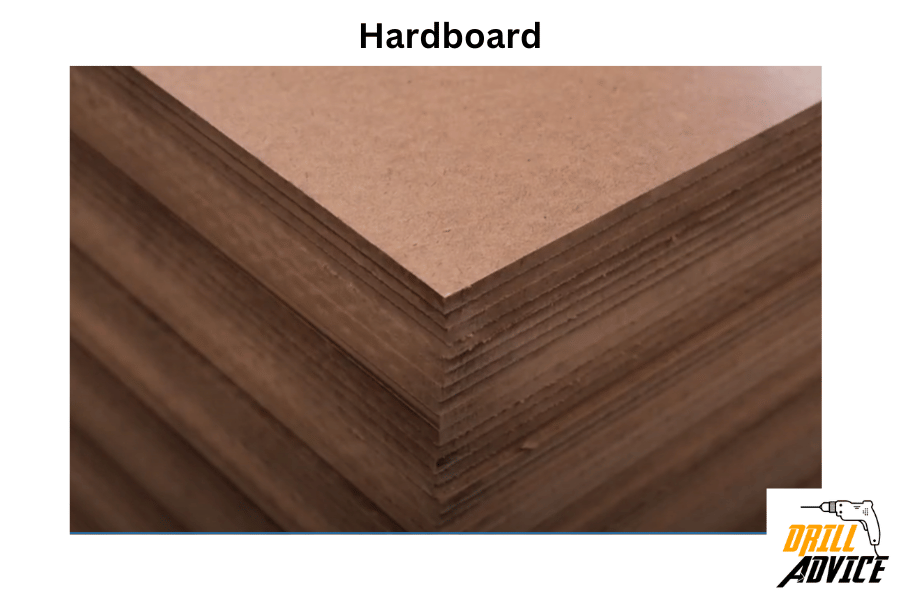

Hardboard

Price: Hardboard has an affordable price. Hardboard is made from compressed wood fibres. But hardwood-type hardboards are more expensive than standard hardboards.

Strength: Hardboard has moderate strength. Its strength comes from tight-packed wood fibres. These fibres intertwine and making it sturdy.

Workability: Hardboard can be cut more clean than some solid woods. Hardboard provides a smooth finish. It’s not exactly like solid wood, but it’s great for many projects.

Maintenance and Care: Hardboard should protect from moisture. Hardboards can be weakened if they get wet. Therefore the hardboard should protect from the water, and dust especially..

Advantages:

- Budget-friendly: Hardboard saves money on projects.

- Uniform Surface: Hardboard is great for painting.

- Easily Available: Hardboard can be found in many stores.

- Good for Panels: Hardboard are good for cabinets or furniture.

- Consistent Quality: Hardboard has a uniform thickness.

Disadvantages:

- Moisture-sensitive: Hardboard should avoid use in wet areas.

- Not the Toughest: Hardboard is not a stronger wood option.

- Can Dent: If the hardboard is hit hard, it might dent.

- Weight: Hardboards are somewhat heavy.

- Not Ideal Outdoors: Weather affects it.

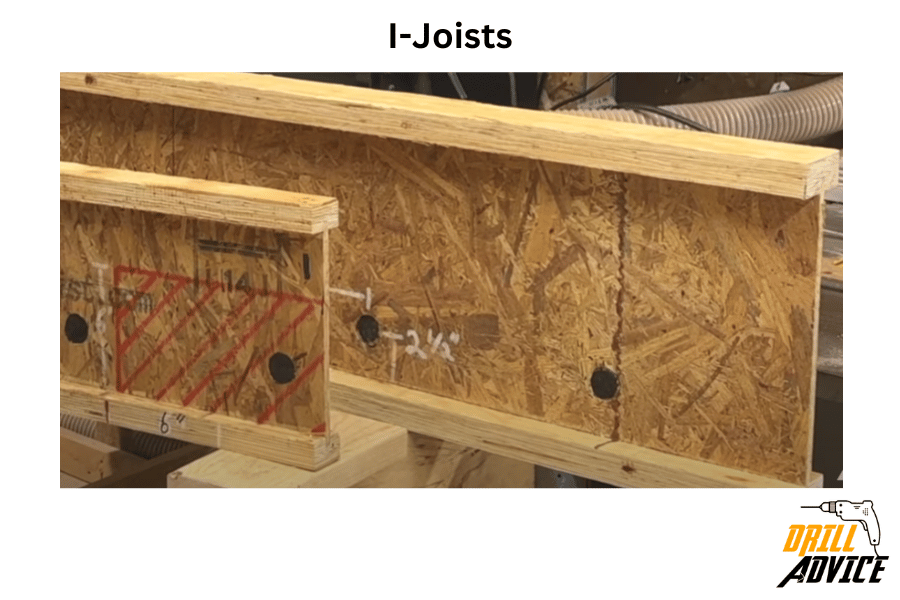

I-Joists

Price: I-Joists are often more budget-friendly than solid lumber. They’re made from smaller wood pieces. Therefore I-Joists can save more money.

Strength: I-Joists are stronger due to its unique shape. I-joist consists of a top and bottom board (flanges) and a connecting piece (web). The grain in these flanges runs long. Due to this I shape design its strength has improved.

Workability: I-Joists are easier to handle than some solid woods. I joist finish is smooth and consistent. Therefore I-joist are good for many roofing projects.

Maintenance and Care: I-Joists need repairs and maintenance during their service life. I joist are not compatible with water, Hence it should always be with free wetness.

Advantages:

- Cost-Effective: I-Joists are cheap engineered woods.

- Strong and Lightweight: I-Joists are easier to handle and install.

- Consistent Quality: I-Joists have predictable performance.

- Flexible: I-Joists are good for floors and roofs.

- Fewer Knots: I-Joists are less imperfections than solid wood.

Disadvantages:

- Moisture Sensitive: I-Joists should not get too wet.

- Not Always Best for Outdoor: I-Joists are not good for outdoor projects..

- Specific Uses: I-Joists are not versatile as solid wood.

- May Warp: I-Joists should store flat.

- Special Tools Needed: I-Joists need certain cuts and installation tools.

SCL uses energy. However, its long life means less frequent replacements, which is better for Earth.

Oriented Strand Board (OSB)

Price: Oriented strand boards are budget-friendly engineered wood. Because it’s made from small wood strands. Plywood or solid hardwoods are more expensive than OSB. OSB is a cost-effective solution.

Strength: OSB is a strong engineered wood. OSB has small wood strands that bond together with adhesives. OSB has a crisscross grain pattern, and it improves the strength of the OSB.

Workability: Working with OSB feels different from solid wood. It’s a bit denser but it can cut well. The finishing of the OSB is not as smooth as solid wood but holds paint and adhesives well.

Maintenance and Care: OSB resists some wear and tear and water. Therefore keep it dry and clean for a long service life.

Advantages:

- Cost-Efficient: OSB is cheap

- Uniform: OSB has a uniform cross-section.

- Durable: OSB are more durable.

- Flexible Use: OSB is good for walls, floors, and roofs.

- Resistant to Warping: OSB are resits to warping.

Disadvantages:

- Moisture Sensitive: OSB can deform with water absorption.

- More Heavier: OSB is more weight than some woods.

- Rough Surface: OSB is not as smooth as other boards.

- Limited Outdoor Use: OSB is suitable for indoor usage. It will get damaged soon outdoors.

- Less Attractive: OSB has no good attractive looking due to its wood parts.

Fiberboard

Price: Fiberboards are cheaper than many solid woods. Because fiberboard is made from wood scraps and fibres.

Strength: Fiberboard is a strong engineered wood type.

Workability: Fiberboard is softer than solid wood. Therefore, fiberboard can cut and finishing smoothly.

Maintenance and Care: Fiberboard should be kept away from water. It can swell and weaken if too wet. Generally, it may need more repairs than solid wood.

Advantages:

- Cost-Effective: Fiberboards are not expensive.

- Smooth Surface: Fiberboards can be painted and veneered successfully.

- Consistent: Fiberboards have a uniform thickness throughout.

- Easy to Work: Fiberboards are suitable for beginners.

- Widely Available: Fiberboards are widely available.

Disadvantages:

- Higher Moisture Sensitive: Fiberboards can wet easily.

- Not Super Strong: Fiberboards are not good for heavy projects.

- Can Chip: Fiberboard edges might chip if not handled properly.

- Heavy: Fiberboards are denser and heavier.

- Limited Outdoor Use: Fiberboards are not good for outdoor projects.