Metal drill bits are essential for metalworking. Different types of metal drill bits are available for different tasks. These types have various diameters, structures, shapes, and point angles which is essential for specific tasks.

The most used 8 type is the twist drill bit, which is used for regular drilling tasks. Center drill bits are another type and it is used for pilot hole drilling. The most used metal drill bits are the twist drill bit, pilot hole drill bit, spotting hole drill bit, counter sink drill bit, metal hole saw, gun drill bits, left-hand drill bits, and ejector drill bit. All these types are used for specific tasks. Hence, you should have all of these if you are a metal worker.

The drill bits’ characteristics are point angle, helix angle flute, shank type,web thickness, manufactured material, usage, pros and cons. When you choose metal drill bits you should pay attention to all of these.

1. Twist Drill Bit

Point angle of the twist drill bit – The point angle, also referred to as the tip angle, is the angle formed at the tip of the drill bit. It is usually measured between 118° and 135°. Lower-bit angles are typically used for softer materials such as plastic, while higher bit angles are used for drilling harder materials.

Helix angle of twist drill bit – The helix angle is the spiral direction of the twist in the drill bit. It ranges from 25° to 40°. A small helix angle is ideal for drilling deep holes, as it allows for efficient chip removal. Larger helix angles allow a higher feed rate and are better suited for drilling shallow holes.

Flute length of twist drill bit – The flute length of a twist drill bit is the length from the tip of the bit to the end of the fluted section. It is generally around 24mm to 150 mm, depending on the size of the drill bit. It is essential as longer flute lengths are used for deep hole drilling, while shorter lengths are used for shallow drilling.

Shank types of the twist drill bit – The shank is the part of the drill bit that goes into the drill machine. It comes in several types: straight shank, tanged shank, or SDS shank. Straight shanks are the most common and can fit into many types of drills. Tanged shanks are used in hand drills, while SDS shanks are used in hammer drills for masonry work.

Web thickness of the twist drill bit – The web is the central portion of the drill bit that links the cutting edges. The thickness of the web can determine the strength and rigidity of the bit. The average web thickness for twist drill bits ranges between 0.020 inches for a 1/16-inch bit to 0.063 inches for a 1-inch bit. Thicker webs are more durable and better suited for heavy-duty tasks.

Twist drill bit materials – Twist drill bits are made of High-speed steel (HSS). Some HSS bits have been combined with tungsten, molybdenum, cobalt, and vanadium in order to improve properties like thermal resistance, friction resistance, and durability.

Usage of the twist drill bits – Twist drill bits can be used on corded or cordless drills, CNC (Computer Numerical Control) machines, drill presses, and magnetic drills can use twist drill bits.

Pros of twist drill bit

- Easy to use and has a minimal set type than other drill bits.

- A cost-effective drill bit.

Cons of twist drill bit

- Each material needs a different point angle. For soft material, it requires a lower angle, and for harder material requires a wide point angle.

Read More About – 7 Types of Drill Bit Materials

2. Center Drill Bits

Center drill bits are often used to create pilot holes for larger twist drill bits or other cutting tools. The pilot hole helps to cutting tools to prevent wandering or slipping off-center.

Point angle of the center drill bit – The center drill bit features a point angle of 60 degrees. This is the angle at which the two sides of the drill bit converge to create the tip. This design is primarily used for creating pilot holes, which guide larger cutting tools and prevent them from slipping or wandering off-center.

Flute length of the center drill bit – The center drill bit has a short and shallow flute length. This design helps to clear chips and debris from the hole being drilled, ensuring a clean and accurate hole.

Shank types of the center drill bit – The shank of the center drill bit can be either straight or spiral. This part of the drill bit is held by the drill press or handheld power drill and transmits the force of the drill to the cutting edge.

Usage of the center drill bit – The main function of these drill bits is to create pilot holes for larger cutting tools, ensuring accurate and precise drilling. Center drill bits are versatile tools used for drilling materials, including metals, plastics, wood, fiberglass, and carbon fiber. They are commonly used in drill presses, lathes, milling machines, and hand-held power drills.

Types of the center drill bits – Center drill bits are generally shorter than twist drill bits and come in two common types: Type A, which forms a center hole with a single 60° chamfer, and Type B, which forms a hole with two chamfers, a 60° chamfer, and an additional 120° chamfer at the start of the hole.

3. Spotting Hole Drill Bit

The spotting hole drill bit can come in a variety of geometrical designs with different cutting angles, most commonly at 90 or 120 degrees. The length of the spotting hole drill bits are shorter than a twist drill bits. Flat-bottomed and stepped spotted bit types are the types of spotting drill bits. These tools are typically covered in HSS and carbide, with coated and uncoated versions on the market. Uncoated drill bits hold the advantage of being easily sharpened.

Flute length of the spotting hole drill bit – The flute length of the spotting hole drill bit is shorter than that of the regular drill bit. This is because spotting hole drill bits are primarily used to create an accurate start for holes, and the shorter flute length allows for greater precision during use.

Shank types of the spotting hole drill bit – The shank type of the spotting hole drill bit is typically straight. This allows for easy attachment to the drill press, milling machine, lathe, or CNC drilling machine.

Usage of the spotting hole drill bit – Spotting hole drill bits are typically used with a variety of materials, including cast iron, plastic, steel, wood, and alloy steel. They can be used in a variety of different machines, including drill presses, milling machines, lathes, and CNC drilling machines.

4. Counter Sink Drill Bit

Counter sink drill bits are essential for removing broken bolts. It rotates anticlockwise direction. When the countersink drill bit is drilling on the broken bolt, it tends to loosen mostly. Counter sink drill bits are available in different materials in order to improve durability and performance.

Point angle of the counter sink drill bit – The point angle of the counter sink drill bit can vary depending on the specific task at hand. The most common point angle of the counter sink drill bits are 60, 82, 90, 100, and 120 degrees. These different angles allow for versatility in use, as they can penetrate different materials and achieve different depths and diameters of holes.

Flute length of the counter sink drill bit – The flute length of the counter sink drill bit refers to the number of cutting edges it has. Counter sink drill bits have 2 main types of flutes.

- Single flute – Has single cutting edge. Suitable for softer materials.

- Two/ three flute – Has two cutting edges and is suitable for harder materials.

Shank types of the counter sink drill bit – The counter sink drill bit has a circular shank type.

Usage of the counter sink drill bit – Counter sink drill bits are essential for removing broken bolts. They rotate in an anticlockwise direction, which tends to loosen the bolt, making it easier to remove. These drill bits are not used continuously but are reserved for special tasks. They can be used with drill presses, bench drills, hand drills, and conventional electric drills.

Availabilities of the counter sink drill bit – They are available in different materials for improved durability and performance and in various sizes, including 9/64, 11/64, 7/32, 5/16, 1/4, 5/8, and 1/2 inch, making them adaptable for a range of tasks.

5. Metal Hole Saw

Sizes and metal hole saw materials – The metal hole saw is available in a wide range of sizes, typically ranging from 1/2″ to 8″1/4 in diameter. The hole saw is made with high-speed steel (HSS) and can include hard materials like carbide, diamond, and tungsten. These materials enhance the hole saw’s durability and expand its usage range.

Shank types of the metal hole saw – The metal hole saw utilizes shank technologies such as SDS-Plus and SDS-Max, especially for bigger sizes. These shank technologies allow the hole saw to be securely and reliably connected to the rotary hammer or demolition hammer. This connection enhances drilling efficiency and reduces the possibility of the hole saw slipping during use.

Helix angle of the metal hole saw – The helix angle refers to the spiral shape of the cutting teeth on the metal hole saw. These can be either straight or helical, often slightly inclined to improve cutting and reduce friction. This design is crucial for the efficiency of the hole saw, allowing it to cut through a variety of materials, including metal, wood, and plastics.

Usage of the metal hole saw – The metal hole saw is a versatile tool used for cutting larger holes in various materials. It is particularly effective on metal surfaces, but it can also be used on softer materials such as wood, plastics, and aluminum. The size, spacing, and shape of the teeth on a metal hole saw can be altered depending on the intended use. Its hollow center enables the removal of the cut material as the saw slices through the material.

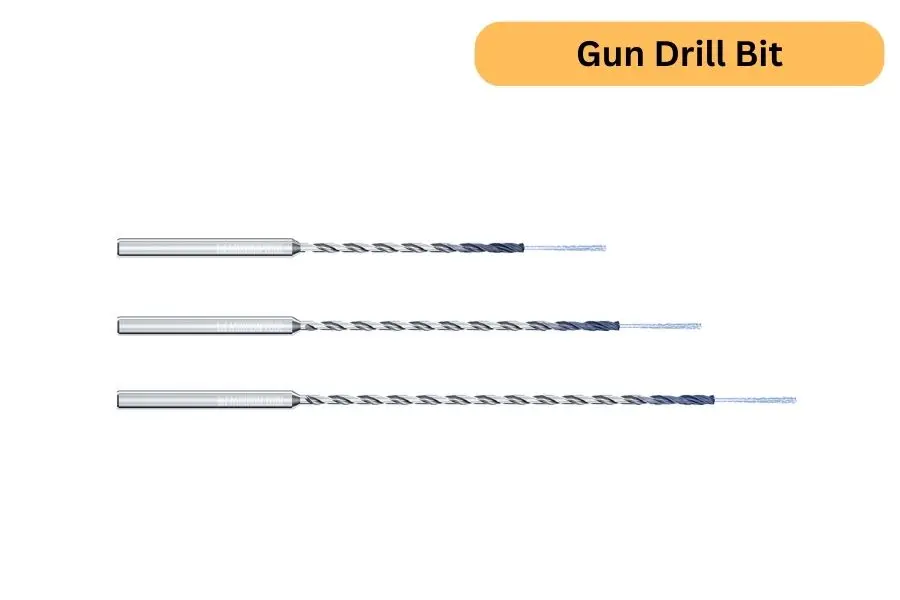

6. Gun Drill Bit

Sizes of the gun drill bit – The gun drill bit comes in a range of sizes including; 1/8”, 5/32”, 3/16”, 7/32”, 1/4”,17/64”, 9/32”,15/16”, 3/8”,13/32”, 1/2”. The price of the gun drill can range from $30 to several hundreds of dollars.

Shank types of the gun drill bit – The gun drill bit has a cylindrical, smooth shank. It is devoid of any flats or notches which allows the bit to rotate easily and reduces the chance of it falling out of the drill chuck while in use.

Usage of the gun drill bit – The gun drill bit is designed for deep hole drilling in metals such as aluminum, brass, steel, bronze, and titanium. It can also be used on plastics and wood. It is often used in conjunction with CNC machine drill presses, which are widely used in the industry.

Materials of the gun drill bit – The gun drill bit is a long, straight drill bit made of either HSS or solid carbide. It has a single, straight flute and a pointed tip that helps guide the bit during drilling. The chisel edge of the bit is useful in reducing cutting forces.

7. Ejector Drill Bit

Ejector drilling is one of three major methods for deep-hole drilling. Deep hole drilling is defined by a ratio of depth to a diameter that exceeds five.

Usage of ejector drill bit – Ejector drill bits can be used to drill holes as deep as 19mm to 102mm (3/4 to 4 inches) and can use in, oil and gas industry, aerospace applications, engines, plastic injection molding, and landing gear. Therefore, it can use for drilling, plastics, construction steel, heat-treated steel, cast iron (alloyed and unalloyed), aluminum and aluminium alloys. Both traditional and CNC machines use ejector drills.

Point angle of the ejector drill bit – The ejector drill bit is designed with a point angle of 1200. This specific angle allows the drill bit to penetrate various materials efficiently, from plastics to heat-treated steel and cast iron.

Shank types of the ejector drill bit – The shank type of the ejector drill bit is hexagonal. This shape provides a firm grip and reduces the chances of the drill bit slipping during operation. It is especially useful when drilling deep holes, as it ensures stability and precision.

The setup for ejector drill bit – The setup for ejector drilling includes a pair of concentric tubes forming the drill tube, a drill head to perform the actual metal cutting, a rotary connector supplying coolant from the spindle through the drill tubes, and an adapter on

8. Left-Hand Drill Bit

The left-hand drill bits’ flutes run in the opposite direction (counterclockwise) and it is best to remove broken bolts and studs. The manufacturing materials of left-hand drill bit are;

Manufacture material and size of the left hand drill bits – Left-hand drill bits are made from various materials including HSS, stainless steel, alloy steel, cobalt, and chrome vanadium steel. These drill bits are slightly more expensive than regular ones. Its size ranges between 1/16” to ½”.

Point angle of the left-hand drill bit – The point angle of the left-hand drill bit can be either 1180, or 1350 . This angle is crucial as it determines the shape of the hole that the drill bit will create. It is important to select the correct point angle based on the material you are drilling into and the type of hole you want to create.

Flute length of the left-hand drill bit – The flute design of the left-hand drill bit can be parallel, straight, or spiral. The flute is the part of the drill bit that removes the material as the hole is being drilled. The type of flute selected depends on the material being drilled and the desired speed of drilling.

Shank types of the left-hand drill bit – The shank type of the left-hand drill bit can be either straight or spline. The shank is the part of the drill bit that fits into the drill’s chuck. The type of shank selected can affect the drill bit’s performance and the type of drill it can be used with.

Usage of the left-hand drill bit – The left-hand drill bit is primarily used to remove broken bolts and studs. Its uniquedesign allows it to free the fractured stud while simultaneously preventing the broken component from being further tightened, eliminating the need for a screw extractor.

Advantages of left hand drill bit – These drill bits offer several advantages such as not requiring a pilot hole, producing rounder and more accurate holes. Choosing the right size and type of bit for the project is crucial, as is the appropriate drilling speed, pressure, and lubricant to reduce heat generation and prolong the drill bit’s lifespan.