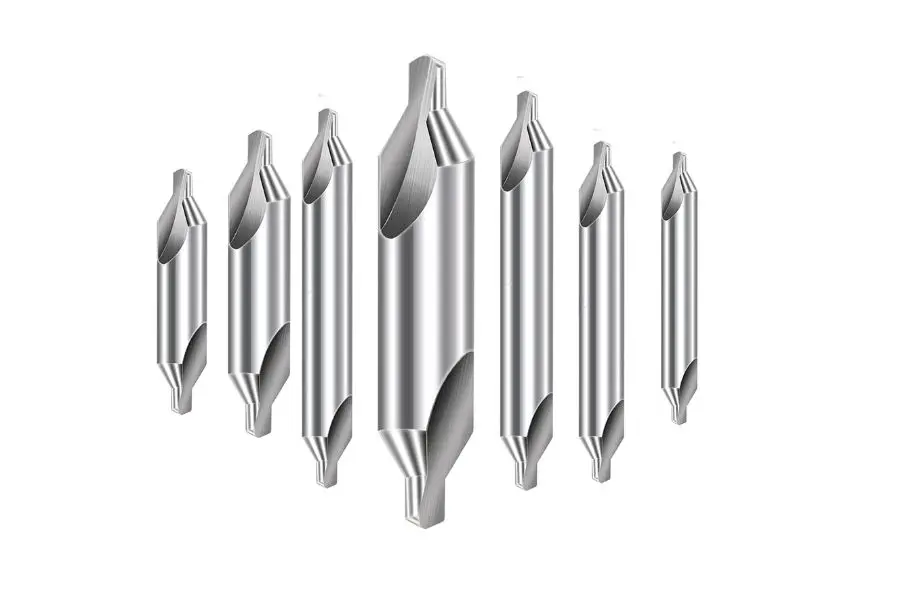

Centre drill bits are often referred to as Slocomb drill bits which is used as counter sink holes or starter holes for bigger drill bits in metalworking. It consists of various angles, such as 60, and 80 degrees and it is made with high-speed steel (HSS). So when you buy a centre drill bit for metal, you should know the following things to choose the best tool every time.

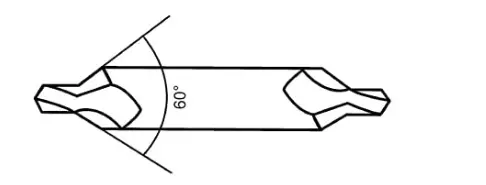

When considering the centre drill bit geometry, its length can be varied 1-4 inches and the end is narrow and tapered with different angles. Not only that, the drill bit tip was also tapered to 60 degrees angle. The jobber length helps to keep the drill bit strictly on point without wobbling and slippering here and there.

What are the Parts and Types of Centre Drill Bit?

The center drill bit is a type of metal drill bit. It consists of two main parts such as,

- The pilot drill

- Countersink

There are two types of centre drill bits based on the centre drill bit angle,

- Type A (DIN 333-A) – Type A creates a center hole with a single 60-degree chamfer.

- Type B (DIN 333-B) – Type B creates a hole with two chamfers, a 60-degree chamfer at the start of the hole and an additional 120-degree chamfer at the end.

- Type R (DIN 333-R) – Type R also features a radius rather than a chamfer. Because there is just one point of contact, this creates a center hole that results in greater gripping accuracy. Still the hole’s load-bearing capacity (ability to endure lateral stresses during cutting) would be reduced.

The start of the hole is shielded against deterioration and deformation that can result in incorrect centering of the tailstock.

What Is the Cutting Angle of The Center Drill Bit?

The basic countersink angles of the centre drill bit are;

- 60°,

- 82° and 90°.

60° is a frequent angle in live centres. The 82° design of flat head screws is followed by a 90° chamfer.

After using a centre drill bit you have to use a countersink drill bit to chamfer the edge of the drilled hole.

When you need to precise pilot hole, you can use a spotting hole drill bit. It has made with carbide and can be used on many metals.

What are the Sizes of Center Drill Bits?

The center drill size can be used to choose the size of the center hole, which can subsequently be controlled by drilling depth.

| Size | Drill Diameter(Inch) | Body Diameter(Inch) | Overall Length (Inch) | Drill Length (Inch) |

| 00 | 0.25 | 0.125 | 1.125 | 0.030 |

| 0 | 0.0312 | 0.125 | 1.125 | 0.038 |

| 1 | 0.0468 | 0.125 | 1.250 | 0.0468 |

| 2 | 0.0781 | 0.1875 | 1.875 | 0.0781 |

| 3 | 0.1093 | 0.250 | 2.0 | 0.1093 |

| 4 | 0.125 | 0.3125 | 2.125 | 0.125 |

| 5 | 0.1875 | 0.4375 | 2.750 | 0.1875 |

| 6 | 0.2187 | 0.500 | 3.0 | 0.2187 |

| 7 | 0.250 | 0.625 | 3.250 | 0.25 |

| 8 | 0.3125 | 0.750 | 3.500 | 0.3125 |

| 9 | 0.3437 | 0.875 | 3.625 | 0.3437 |

| 10 | 0.375 | 1.000 | 3.750 | 0.375 |

What is the Color and Material of the Center Drill Bit?

Because the centre drill bit is used for metals, its hardness must be higher than the metal for successful drilling. Various manufacturers made the centre drill bit to drill a range of hardened metals.

The colour of the centre drill bits is;

- Silver

- Gold.

The colour of the centre drill bit depends on the coatings also. So there have a few more coating types. Those are;

- Titanium Aluminum Nitride – Because of that, the drill bit looks like a black-coloured drill bit.

- Titanium

The materials of the centre drill bits are;

- High-speed steel

- Carbide

- Alloy steel

- Brass

The carbide centre drill bit is durable and able to withstand heavy use.

What is the Usage of Center Drill Bit?

In metalworking applications, they make holes in the centre of stock so it can be spun between centers on a lathe. To prevent damage to the lathe’s centers when the stock is spun on it, the pilot drill makes a tiny hole in the stock, and the countersink enlarges it, leaving a tiny space at the bottom of the hole.

When you need to drill a pilot hole in a proper way, this guide will help you in detail.

Under that, center drill bits can use to drill holes on steel, iron, alum, carbon steel, brass and other materials range from 170HB up to 200HB using lathe machines and the majority of electronic drills.

What are the Pros and Cons of Center Drill Bits?

These are the pros and cons of center drill bits.

Pros of center drill bits

- High precision and accuracy.

- Provides a guide hole for larger drill bits.

- Reduces the chances of drill bits wandering off-center.

- Can be used on a variety of materials.

- Durable and long-lasting.

- Easy to use and install.

Cons of center drill bits

- Not suitable for large drilling tasks.

- May require frequent sharpening.

- Not ideal for deep hole drilling.

- Can be more expensive than other drill bits.

- May require specialized equipment to use effectively.

- Not as versatile as other types of drill bits.

05 Tips to Use Center Drill Bits

Follo these 5 tips when using a center drill bits.

1. Select a suitable size drill bit – As mentioned earlier, there is a market centre drill bit range of various sizes. After determining the size of the hole you need, you should select the appropriate centre drill bit.

2. Use lubricant oil for efficient drilling – Applying lubricant can prevent friction between the centre drill bit and the metal surface and control the temperature. Therefore, accidents can be avoided by breaking the bit.

3. Must be careful about the tip of the drill bit – As mentioned earlier, some of the centre drill bits have coatings. Therefore, those types of drill bits cannot re-sharpen. Like that, drill bits must be carefully observed before drilling. Damaged or blunt edges make accidents.

4. Must be careful when drilling deeply – Drilling too deeply will result in the centre only making touch with the hole’s sharp outer edge, which is a poor bearing surface.

5. Use Lower RPM – This step prevents damage from breaking the drill bit. For accurate drilling, start slowly and gradually increase the speed to an appropriate RPM.