When you need to fasten the screw to the wood or metal workpiece without showing its head, you should use a counter sink drill bit.

Normally, counter sink drill bits are two different sizes. The jobber-length counter sink drill bits are used for woodworking, and stub-length drill bits are used for metalworking. So many types of counter-sink drill bits with different geometries are available in the market.

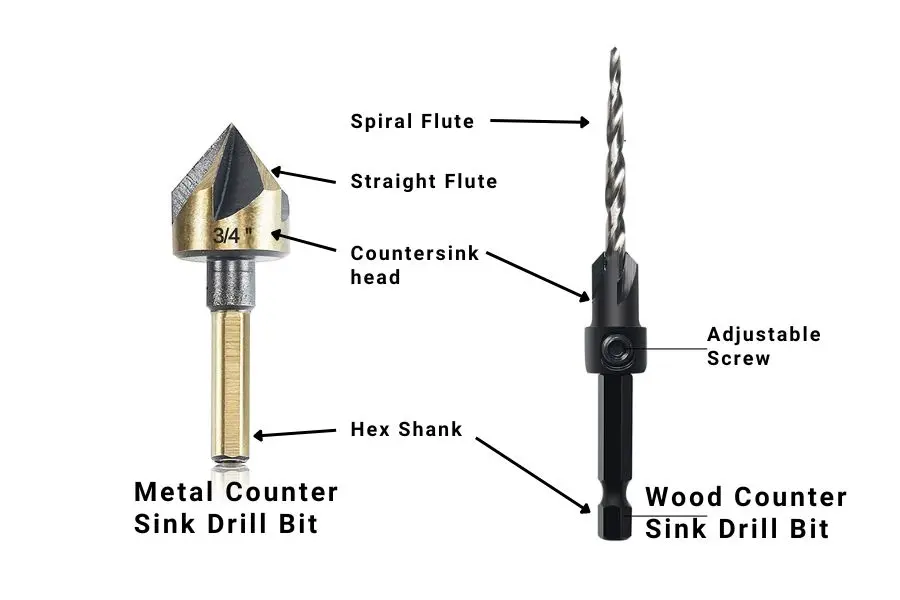

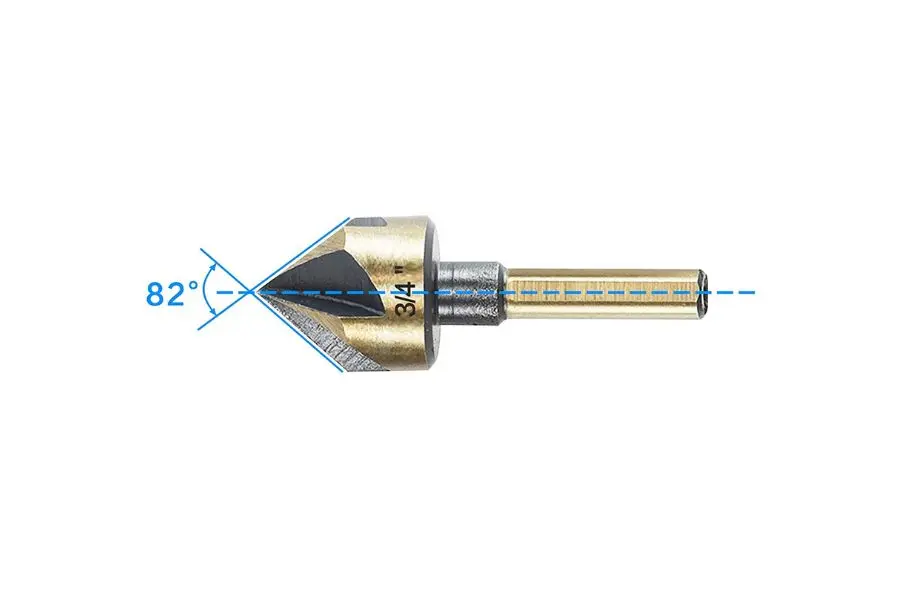

Counter sink drill bit is used for woodworking and metalworking to chamfer the drilled hole’s open edge. Counter sink drill bits are made with high-speed steel and coated with TiN, TiAlN and TiCN to improve durability and heat resistance. Normally counter sink drill bit has an 82 degrees angle that helps to chamfer the open edge of the drilled hole according to the exact angle of the screw head.

Wood counter drill bits are two parts, such as countersink head and spiral flute, and metal counter sink drill bits have only counter sink heads only. So let’s see all in detail about counter sink drill bits and usage.

What are the Parts of a Counter Sink Drill Bit?

Normally, counter sink drill bits consist of a few parts, such as,

- Shank

Shank is the driving end of the drilling machine.

According to the cross-section of the shank, shanks are two types. Cylindrical shank and hex shank are them.

Cylindrical shank drill bits can fit easily with the 3 jaws chuck, and hex shank counter sink drill bits can be used on a keyless chuck.

- Cutting Edge

Cutting edges are typically odd in number. This makes countersinking a smooth operation. The countersink will slip slower and be simpler to operate with a hand drill.

- Profile of Flute

The flute profile is the same as the regular drill bit for the wood counter sink drill bits. But in the metal counter sink drill bits, there is no flute. There is a straight flute type.

What Are the Two Types Of Counter Sinks Drill Bits?

There have two types of counter sink drill bits based on flute type.

- Spiral

- Straight

Spiral counter sink drill bits

- Spiral countersink drill bits are wood drill bits.

- Wood countersink drill bits can be used for drilling pilot holes in the woods.

- This type of counter sink drill bit is made from classic carbon steel material.

- Therefore, it has high hardness and offers superior cutting power and durability.

- The three-pointed tip gives quickly and accurately drills a smooth hole. Better in centering and has no skid.

- The chips will automatically fast discharge from the hole on both sides by a five-edged chamfer design.

- It is easy to use the combination of a hex key to adjust or disassemble the countersink drill bit and the five-flute chamfering.

- These drill bits are suitable for bench drills, hand drills and conventional electric drills.

Straight counter sink drill bits

- The self-starting point starts with contact with the material.

- It has a balanced double flute.

- This shape of the drill bit eliminates chatter and vibration.

- Holes are automatically deburred by the trailing flute.

- Re-sharpenable cutting-edge enables longer tool life.

What Are the Sizes Of Counter Sink Drill Bits?

Three flutes are normally present in this type of drill bit to ensure a smooth flow during countersinking. In the current drill hole, the conical form causes deburring or countersinking.

This enables the proper positioning of a countersunk head screw.

The variety of countersink bits’ uses also explains why the product is available in a range of sizes. They come in many sizes, including 16.5mm, 20.5mm, 25mm, 35mm, and 40mm.

Angles of varying diameters are created for the fixing to fill according to the size of the drill bit used. A 3-face shank is an additional option to the common cylindrical shank and the Morse taper bit shank.

These different shank designs decrease tool slippage.

What Are the Available Shank Sizes Of Counter Sink Drill Bit?

The portion of a drill bit or other bit that is inserted into a drill, router, or other tools that accepts a bit is called the shank.

There have a few types of shank sizes.

A shank is typically the same size as the drill bit, as evidenced by the bit’s shaft. The most popular sizes for Counter drill bit shank sizes are 1/4″ and 1/2″.

The straight shank has the advantage of being accurate in its centering. A straight should not wobble at all. However, a hex may wobble somewhat.

What Are the Colors and Materials of the Counter Sink Drill Bit?

Materials of counter sink drill bits are;

- HSS steel

- Speed steel

- Carbide,

- Tungsten,

- Tungsten Steel

- Some manufacturers are using a mixture of high-speed steel, stainless steel, and alloy steel.

The counter sink drill bits have coatings. Those are;

- Nano titanium

- Black Oxide

- Black oxide is preferable to a brilliant finish in terms of lubricity.

- In comparison to plain HSS, countersink drill bits with a black oxide coating endure 50% longer after extra heat treatment.

- Titanium Nitride (TiN)

- Designed for drilling through rigid material.

- They can be easily identified with their rich gold hue coating.

- Titanium Aluminium Nitride (TiAlN)

- Titanium, aluminium, and nitrogen make up TiAlN as a compound.

- Highly versatile and widely used.

- As a result, heat and oxidation are not a problem for the coating.

- Golden oxide

- Resist the drill bit by corrosion and have a long service life.

What Is the Cutting Depth Of Counter Sink Drill Bit?

Counter Sink Cutting Depth For Metal

Mostly counter sink drill bits are not designed for the drilling purpose on metal. It uses to taper the open edge of the drilled hole.

When you use counter sink drill bits, you can’t drill deeper. Because there is no flute design and chips are not able to remove easily. So countersink drill bit will heat easily.

Counter Sink Cutting Depth for Wood

The cutting depth should be set according to your requirement. Adjust the countersink’s height to correspond to the length of your screw.

To accomplish this, place the matching hex wrench into the side hole and tighten it. Then adjust it to meet the screw’s depth for your project by raising or lowering it.

Set the drill bit’s tip in alignment with the earlier mark.

Start the drill at a faster speed to thoroughly sink the bit, then reduce the speed to create the countersink. The countersunk hole can become overly deep or tear out if it is drilled too quickly.

Where to Use Counter Sink Drill Bits?

A tapered countersink bit is a versatile drill bit.

- You can completely conceal the fastener by drilling a countersink slightly deeper than the fastener head.

- When drilling a hole through metal or plastic, burrs may form. A burr is an unintended material protrusion that results from milling. A countersink can be used to deburr the hole’s sides by removing the deburred area first.

There have a few tips for using counter sink drill bits.

Drilling the hole deep enough so that the screw head is flush with the surface requires a little practice. Before drilling holes in your project, try drilling countersink holes on a few test components.

Slowly drill the holes. Otherwise, drilling too quickly may result in excessively deep countersink holes. High-speed drilling can produce “chatter.”

What Materials Can Be Drilled Using Counter Sink Drill Bit?

They are the best for hard-to-drill. Under that, screw holes can be drilled into;

- Wood – Softwood, Hardwood

- Plastic

- Fiberboards

- Particle board

- Plywood

- PVC

- Metals – Cast iron, brass, and aluminum etc.

Read More About

- What is Spade Drill Bit?

- What is Forstner Drill Bit?

What is the Difference Between a Countersink Drill Bit and a Centering Drill Bit?

Counter sink drill bits and centering drill bits can be used on metal. Center drill bits are used to drill pilot holes on the workpiece, and counter sink drill bits are used to chamfer the outer edge of the drilled hole.

Both are essential for the better finishing of the workpiece.