When using a chainsaw, we have to face many problems. Among them, a chainsaw flywheel stuck is one of them. A chainsaw flywheel can be stuck due to many reasons. In this guide, I will explain why a chainsaw flywheel is stuck and how we can fix it easily. So let’s move into the topic.

A chain saw flywheel is stuck when there is a problem in the flywheel and crankshaft line. This can be happened due to damage to the flywheel, jamming the flywheel and bent or broken flywheel. When it is stuck, the chain is not moving.

You can fix this easily by using simple tools that can be found around you. There are some tips and tricks to share with you. So keep reading on!

What is a Chainsaw Flywheel?

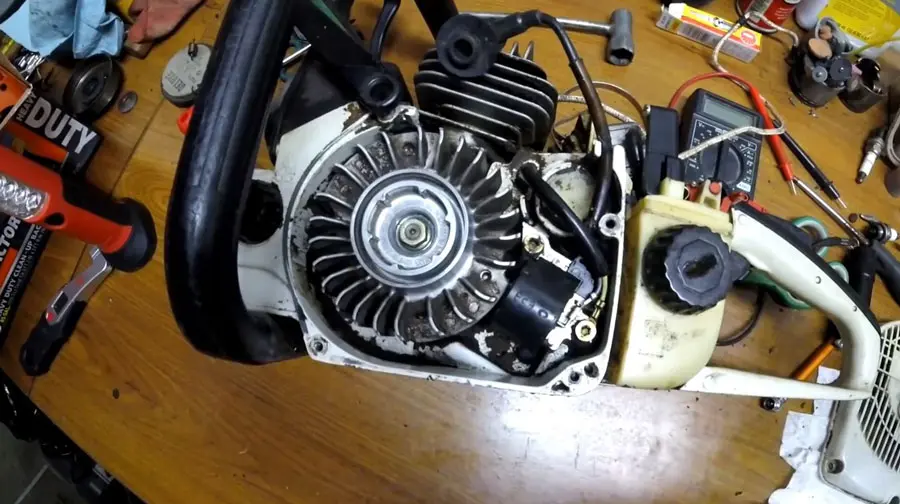

A chainsaw flywheel is a mechanical device that stores rotational energy and helps to regulate the engine speed (RPM). It has two main functions: it keeps the chainsaw running at a consistent speed, even when it’s working through tough, dense wood, and it helps to cool the chainsaw. The fins on the flywheel blow air across the chainsaw engine, keeping it from getting too hot. The flywheel also assists in creating the spark of the ignition system as it contains magnets passing over the ignition coil.

Why is Chainsaw Flywheel Stuck?

There are reasons to stuck the chainsaw flywheel. Normally, when it is stuck it can’t rotate as well as sometimes it is not able to loosen and remove easily. So let’s see, what are the reasons to stuck the chainsaw flywheel?

What are the Reasons to Stuck Chainsaw Flywheel?

There are several things that can impair the performance of the flywheel. They are;

- The flywheel is damaged.

- The flywheel becomes jammed

- The Flywheel key is bent or broken

- Due to crankshaft seals/bearing problem

The flywheel will cease to move, and the chainsaw will be stuck.

And also, the flywheel connects to the crankshaft through a thin metal piece and it can call the key. Any problems along this line can cause the flywheel to get stuck.

What Happens When Chainsaw Flywheel Is Stuck?

When a chainsaw flywheel is stuck, you can observe the below problems

- Difficulty in starting the chainsaw.

- Inconsistent chainsaw speed.

- Overheating of the chainsaw engine.

- Inability to maintain engine speed.

- Poor performance in cutting.

- Possible damage to the ignition system.

- Inability of the chainsaw to operate.

- May cause the chainsaw to make unusual noises.

- Damage to the engine’s piston and cylinder.

- Decreased lifespan of the chainsaw.

How to Fix Chain Saw Flywheel Stuck?

In the event of a device failure, trying to restore the device is cheaper than buying a new device.

Instruments to Fix Chainsaw Flywheel Stuck

- Screwdriver

- Pliers

- Socket wrench (13mm)

- Piston stop tool

- Nylon rope(Not essential)

- Impact wrench

- Flywheel puller

- White spirit

- Replacement parts (as needed)

How to Fix Chain Saw Flywheel Stuck?

Let’s check out the 8-step repair method for a stuck flywheel

Step 01 – First, unscrew and remove the cylinder cover above the engine, protecting the cylinder and air filter. Also, unscrew and remove the boot cover on the side, protecting the boot area.

With the starter cover in your hand, pull the starter rope and see if it automatically retracts from the pulley.

- If not, replace the initial recoil assembly.

- If it spins, your problem is clearly a deep-seated problem in the engine.

Step 02 – Turn the flywheel by hand to identify the problems related to the flywheel. But if it only spins if you push hard, your key is cut and will need to be replaced. If the flywheel does not spin, your problem is further in the engine; you need to remove the flywheel.

Step 03 – Use the plier to disconnect the lead ignition wire. An Ignition wire runs to the “stop” switch from its post on the ignition module. It is to the left of the flywheel.

And also, disconnect the HT lead wire from the spark plug by removing the rubber boot. Lift both wires from their cable guide above the flywheel after slowly lifting them out of the engine.

Step 04 – Make sure the spark plug is unscrewed and lift it out. Use the socket wrench for it. Then push the piston stop tool into the open plug neck. If you fear damaging the piston of the flywheel by using a metal piston, you can use a nylon rope.

The nylon rope must be included in the cylinder. Although must make sure the piston is above the exhaust port and other ports in the flywheel. If you decide to do this method, be very careful. Because this nylon thread gets caught between the piston and other holes, it can cause a lot of damage to the machine.

Step 05 – Unscrew the two bolts holding the ignition module on the engine and lift the module out of the engine, slowly and carefully. Unhook and remove the two starter pawls from the flywheel.

After that, loosen the flywheel’s center bolt until the bottom edge comes in line with the flywheel. Set the flywheel puller over the flywheel and tighten the two outer bolts on the puller. It helps to grasp the flywheel.

Step 06 – Tighten the center bolt of the flywheel puller until the flywheel comes loose from the crankshaft. A chain saw can use only a 13-millimeter socket to remove the nuts. It can typically be between 13 millimeters and 16 millimeters. Now we can identify the faults of the flywheel of the chain saw. An impact driver can use for this task. Counterclockwise rotation of an impact driver will help with this.

Step 07 – Remove the nut, washer, flywheel and puller. Separate them and after wash the flywheel in a white spirit. After the wash, we can check the flywheel for signs of bent or damaged spokes. Must identify any cracks on the underbelly of the flywheel.

Remove the key from the slot in the crank. Replace the key, if it’s bent or damaged.

Step 08 – Check the crankshaft as a final step. Therefore, turn the crankshaft by hand. It should spin a few rotations. If it doesn’t spin, unfortunately, the problem lies in the crankshaft, piston, or cylinder. Most of which are very expensive to fix. Install the flywheel key, flywheel, ignition module, wires, and the rest of the starter. Be sure to install these in reverse order.

How to Remove Stuck Chainsaw Flywheel?

Sometimes flywheel can be tightly stuck with the crankshaft. So you can follow these steps to remove it easily.

- Apply a little bit of pressure on the flywheel with a puller

- Rap the centre of the puller hard with a hammer at the point where you normally apply the wrench

- If the flywheel is partially stubborn on its taper, apply a gentle amount of heat to the flywheel to expand it.

- You can mix up a 1:1 ratio of automotive transmission fluid and acetone, put a drop or two on the crankshaft, let it sit overnight and try again.

If the wheel cannot remove, you can follow this guide.

How to Avoid Chainsaw Flywheel Stucking?

Basically, if any device is operated for a long time, the temperature of that device may increase and the performance may be affected. Therefore, it is best to operate the chain saw at proper intervals.

If the device makes a different noise when it is in operation, taking care can prevent major damage to the device. Also, the chain saw should be maintained by applying suitable lubricants.

Regular and careful cleaning is also a very important step. The teeth of the cutting blade of the chain saw should be cleaned, the outer cover of the device should be removed, and the debris, including small wood chips inside, should be removed slowly. Or this waste will interfere with the operation of the equipment. As a result fo this, chain saw chain will be dull over time.