A Circular saw is one of the most used saw in woodworking. We can observe so many problems when we use a circular saw in day-to-day activities. If you buy a new circular saw or if you are a newbie for woodworking, as a first time using a circular saw, you can see your cutting is not straight as you wish. But it is not a serious problem. You can fix it quickly after referring to this guide until the end.

A circular saw is not cutting straight due to poor saw blade, sliding workpiece, warper saw blade, loose or dirty blade, and less practice and experience of the user. A straight-cutting problem can fix easily by using a proper saw blade, lower cutting speed, clamped workpiece, and proper skills.

These factors are the reasons, but there are also many reasons for the circular saw not cutting straight. So let’s see, what are the reasons and solutions for the circular saw not cutting straight step by step.

What are the 07 Reasons for Circular Saw not Cutting Straight on the Workpiece?

This is the essential thing that you should know. Before fixing the problem, we must know the reasons. According to the experience, I could gather many reasons. So if you have such a problem, check whether you have one of these reasons. So it will be easy to fix the problem.

1. Circular Saw Blade is not Parallel to the Edge of the Base

If the blade is pointed towards the edge, then it would press the saw harder against the guide, and assuming the guide is secure and doesn’t flex, this would get a straight line but a wider kerf.

If it is pointed away from the edge, then it would want to pull the saw away from the guide. In that case, you would have to use your arm strength to keep it against the guide (or twist the saw a little). That makes it a challenge to keep it against the guide.

2. Fast Feeding Rate of the Circular Saw

When you cut using the circular saw, you should not be rushed. If you rush, you will not be able to cut along the cutting path it will move here and there. The result will be a crook cutting path. So be calm and wear the essential safety instruments such as goggles, hearing protection equipment and wear blouse then start the work without any stress and hurry.

When your feeding rate is high, chips can be clogged inside the kerf. As a result of this, we can see circular saw smoking. So, always use the correct and sufficient feeding speed.

3. Loose Circular Saw Blade

When a circular saw is used for a long time, the saw blade holding the nut can be loosened. As a result of this saw arbor cant carry the saw blade on the correct path. This will cause to misalign the saw blade. Finally, we can observe saw blade is sping with a wobble. As a result of this, we cant move the saw blade on the correct path. And also, we can see the kerf path is wider than the blade thickness.

Normally, the saw blade is tightened counterclockwise to make the blade loose from the arbor. Hence it is easy to tighten the saw blade.

4. Warped Circular Saw Blade

A poor-quality saw blade can be warped due to its low-quality material. Normally saw blades are made with tough materials such as tungsten, carbide, etc. To minimize the production cost, manufacturers use low-quality materials. So it is better to select the right saw blade for your project.

As a result of this saw, blade strength is reduced, and it can be damaged easily. When the hardwood or sudden metal part is cut it will be a blunt blade. And also, these kinds of saw blades can bend easily. Not only bend those can dirt easily due to outer surface material.

5. Less User Experience and Practise of Circular Saw Using

This is a very important thing that we must keep in mind. The first time we use a circular saw, we will not be able to use it like a pro. Its noise, vibration, weight are not compatible with us. I remember my first time using a circular saw. It vibrated the side of my body. But after using it several times, I could cope with the tool.

When you try to straight cut at your first time it will be crooks and curved. Sometimes cutting path looks like a snake. So don’t worry, time will fix everything. Nobody does it as a professional user for the first time. Sometimes you may need to throw away a few workpieces. But those will be an investment for the future time and money. Don’t worry about it.

But as a newbie, you should be careful about safety. You must always follow the proper safety guidelines in order to you and tool safety.

6. Using a Low-Quality Circular Saw Blade

Saw blade quality is very important for the perfect cutting process. The quality of the saw blade cannot be identified by the visibility. You have to use it for confirmation. Imagine if you buy a cheap circular saw with a saw blade, probably, saw blades will be cheaper and lower quality.

You can observe it by using it. Some circular blades that come with circular saws are not good. Frankly, those can be used one or two times. One of my friends bought a circular saw for 50$. When it used to cut the workpiece, it was not straight, and after a few cuts, we could see blunt saw teeth.

- A high-quality saw blade doesn’t scrimp on carbide or steel. It has been made with long-life materials and teeth have been designed as it resharpened many times.

- Low-quality saw blades are made with thin stamped steel plates. Expansion slots end bluntly in open holes signal old technology and a noisy blade.

7. Sliding the Workpiece Here and There

When we cut, the workpiece should be fixed; when it moves here and there, we can’t cut it. This is common for any sawing and drilling process. If the workpiece is sliding, you cant cut it properly. Sometimes you can see kickback and binding in the workpiece. Due to binding the workpiece, we can see burning marks on the workpiece.

If the workpiece is not stable, you can use a clamp to fix its side. You can find any size of the clamp in the market. If you are not able to use a clamp, ask someone to tightly fix it until you cut it. More than that you can screw desired points as it does not move here and there. But it is not a recommended way.

And remember, when you clamp the workpiece, make sure to use a way, as it is not binding with the saw blade.

How to Fix Circular Saw not Cutting Straight?

1. Use Saw Track or Rail Guide When Using a Circular Saw

In order to cut straight, you can use a saw track or fence. These tools are not the same.

Saw Track

Saw tracks can hold the circular saw shoe on the holding panel. Using screws, you can tighten the circular saw withholding panel well. Then holding panel can move on the tracks smoothly. A saw track is about 50″ in length. Hence it can be used for long-cutting purposes.

You have to align the cutting point and place the saw track on it. Then, switch on the circular and then slowly cut the workpiece.

Kreg is a leading manufacturer of the saw track industry. We can see Kreg rip cut and Kreg Accu cuts.

Use Kreg Rip-Cut

Normally Kreg rip cut is used as the short circular saw guide. It can cut 24″ in length rip cuts easily. Due to the lightweight 2.45 lbs, it can be handled easily, and it will cost about 35$-45$

Use Kreg Accu Cut

Kreg Accu cut is designed for the long accurate cuts such as 48″ in plywood. Due to the length, this is a bit difficult to use for the smaller workpiece. It is suitable for large workpieces.

Saw Fence

Saw fence is another tool used for straight cutting. The saw fence will act as a guide. It can clamp two sides of the ends. Then circular saw show can move along the saw guide. You just need to push along the guide edge. Then saw blade will move along the saw guide.

2. Fix Circular Saw Blade With Proper Alignments

Alignment is an essential thing we must consider in the circular saw blade. A proper circular saw blade should be well flat and have sufficient strength. It can fix the arbor by tightening the outer flange and tightening the nut. When you tighten the saw blade make sure the inner flange, arbor, outer flange, and washers are with proper quality and free of surface damage.

Blade alignment does not affect much to the straight cutting much. Due to the wrong blade alignment blade can be wobble. As a result of this, we can see wider kerf.

3. Clamp the Workpiece

This is a simple task. You can use clamps to tighten the workpiece with the table or platform. When you use a clamp make sure the clamp does not block the cutting path. You can buy any size of clamp from the market.

If there is no clamp, ask someone to tight well. Then, you can cut along the cutting line path.

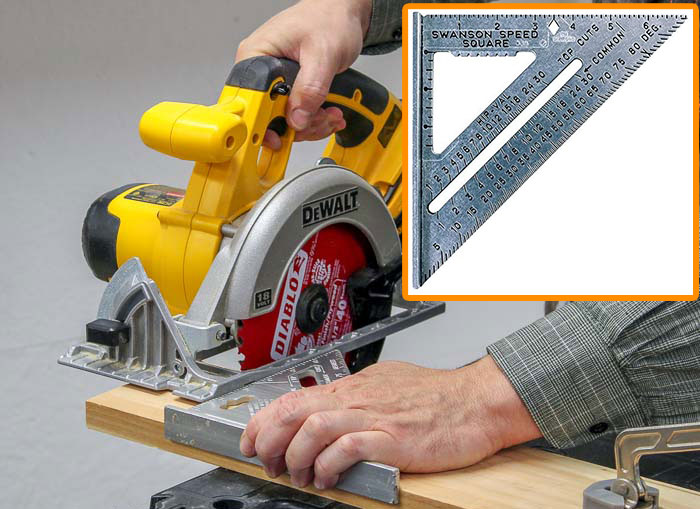

4. Use a Speed Square While Using a Circular Saw

A speed square is made with metal, and it is really suitable as a short guide. If you have to cut less than 8 inches, you can use a speed square as a guide fence. According to your requirements, you can buy a 7″-12″ speed square in the market. This a very useful tool that you should have.

5. Replace a Warped Circular Saw Blade

Most of the warped saw blades are not able to use for straight cuttings. If a saw blade is damaged due to sudden flexibilities, it is difficult to fix it completely, even a slight bending or abnormal spinning in the saw blade. This behaviour can be observed in the low-quality cheap saw blades.

You can identify the saw blade before it is tight to the circular saw. Just keep the saw blade on the flat surface. If the saw blade surface completely touches the flat surface, it will be a perfectly flat blade.

If some part of the saw blade touches the surface at a time will be a sign of a warped saw blade. Hence it should not be tight to the circular saw. It will avoid straight cutting in the circular saw.