Hammer drills are really worth it for concrete drilling. Concrete is one of the hardest manufactured materials in the world. It consists of aggregate, cement, and rebars. So when you need to drill through concrete, you should have a hammering action with a masonry drill bit. So many hammer drills and drill bits are available in the market. So let’s see, what are the best hammer drills that we can use for the concrete.

Before you buy a hammer drill, you should pay attention to the below matters. So let’s see, what you should know before buying a hammer drill.

What You Should Know Before Buying a Hammer Drill?

It is really important to choose a hammer drill. Because many hammer drills are available in the market with different performances.

So when you buy a hammer drill you should know the meaning of the below terms.

1. Blows Per Minute (BPM)

The hammering mechanism is moving the chuck with the drill bit forward and backward with spinning. Percussion rate is the same thing that you should know. Due to the movement, it can crush the forward material into chips. Hammering actions are two types.

- Chuck Moving (Regular Hammer Drill)

- Drill Bit Moving (SDS, SDS Plus, and SDS Max)

The hammering action is measured by BPM (Blows Per Minute) the higher BPM is better than the lower.

2. Regular Hammer Drill

The regular hammer drill is used to drill light tasks such as drilling brisks, concrete, motors, etc. These are with small size drill bits and are used to drill non-heavy-duty tasks.

There is a difference between a hammer drill and a regular drill. So you should know about this before you buy it.

3. SDS Hammer Drill

SDS hammer drill has higher hammering action. These tools have a moving drill bit rather than a moving chuck. There are types of SDS hammer drills such as SDS, SDS Plus, and SDS Max. Each one has a different shank design.

SDS hammer drills are used to drill heavy-duty tasks such as drilling concrete, stone, concrete with rebars etc. So If you have a heavier task, you should use an SDS hammer drill

There is a difference in SDS Vs SDS Plus and SDS Plus Vs SDS Max hammer drill. So you should know them and their usage properly.

4. RPM (Revolution Per Minute)

This is called how many times a drill bit can sping with a minute. High RPM has lower torque and lower RPM has higher torque. When the tool is operating it will vary according to the required drilling force.

What You Should Know Before Buy a Hammer Drill Bit?

When you buy a hammer drill bit, you should pay attention to the material it has made. Mostly concrete drill bits are made with HSS (high-speed-steel), Titanium, Tungsten, and Carbide materials. Those are extremely tough and can be used to drill tougher material with high heat resistance and abrasion resistance.

More than that there is a smooth flute design with a strong drill bit head which is made with Tungsten carbide material.

The hammer drill bit tip is not designed as a well sharp one. It looks dull but strong. So, you should pay attention to the tip material of the drill bit when you select a hammer drill bit.

Our Top Pick Hammer Drills for Concrete

This guide help you to find the best hammer drill you need. First I have mentioned regular hammer drills and others all are for heavy-duty drilling and chiseling SDS hammer drills.

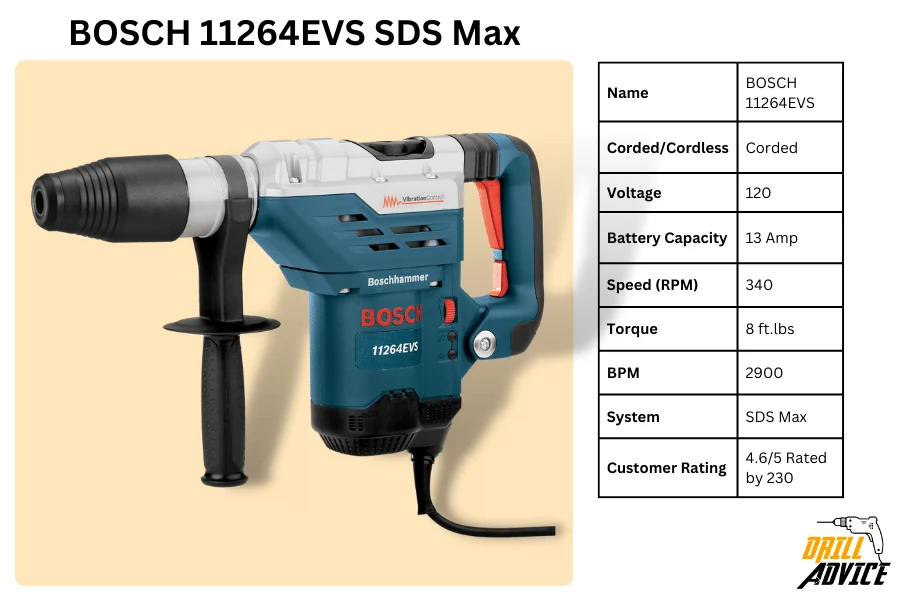

BOSCH 11264EVS SDS Max

BOSCH 11264EVS is an SDS Max hammer drill that can be used on harder materials such as concrete with reinforcement. You can use SDS Max drill bits and chisels in this hammer drill. This is a combination hammer with 03 modes called rotation-only, rotary hammer, and hammer-only mode. This corded electric drill can be handled using one hand. User-friendly design and light weight will increase the durability of the tool.

| Name | BOSCH 11264EVS |

| Corded/Cordless | Corded |

| Voltage | 120 |

| Battery Capacity | 13 Amp |

| Speed (RPM) | 340 |

| Torque | 8 ft.lbs |

| BPM | 2900 |

| System | SDS Max |

| Customer Rating | 4.6/5 Rated by 230 |

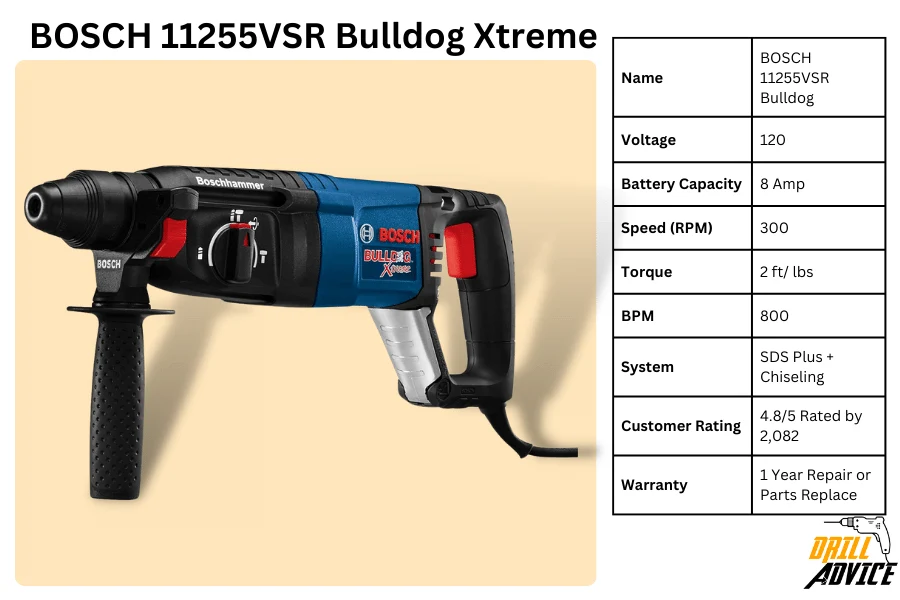

BOSCH 11255VSR Bulldog Xtreme

| Name | BOSCH 11255VSR Bulldog |

| Corded/Cordless | Corded |

| Battery Capacity | 8 Amp |

| Speed (RPM) | 300 |

| Torque | 2 ft/lbs |

| BPM | 800 |

| System | SDS Plus + Chiseling |

| Customer Rating | 4.8/5 Rated by 2,082 |

| Warranty | 1 Year Repair or Parts Replace |

BOSCH 11255VSR Bulldog Xtreme is an SDS plus hammer drill that we can use for drilling concrete as well as chiseling. It has been designed as a user-friendly design that can provide more force and handle the tool easily. It is a corded electric drill. You can use both drill bits as well as chisel here. It has 3 modes such as rotation-only, rotary hammer, and hammer-only mode. But this is not suitable for using reinforced concrete.

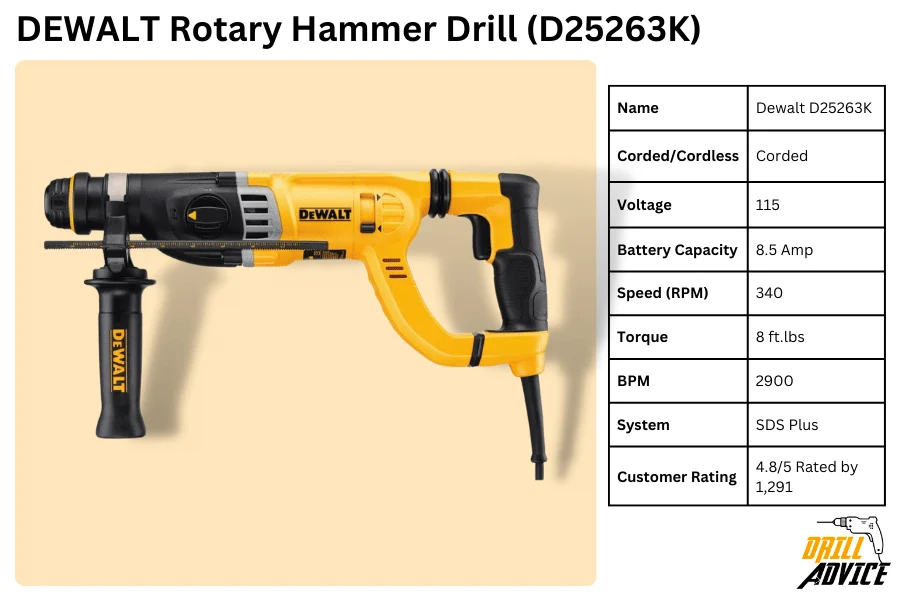

DEWALT Rotary Hammer Drill (D25263K)

| Name | Dewalt D25263K |

| Corded/Cordless | Corded |

| Voltage | 115 |

| Battery Capacity | 8.5 Amp |

| Speed (RPM) | 340 |

| Torque | 8 ft.lbs |

| BPM | 2900 |

| System | SDS Plus |

| Customer Rating | 4.8/5 Rated by 1291 |

DEWALT Rotary Hammer Drill (D25263K) is a buldog type hammer drill that can be used for the drilling and chiseling. It is a corded electric drill which can be used for the havy duty task such as demolishion and chiseling etc. Active vibration control reduces the vibration felt by the user at the handles. You can buy it with 5 pcs hammer drill bit set also.

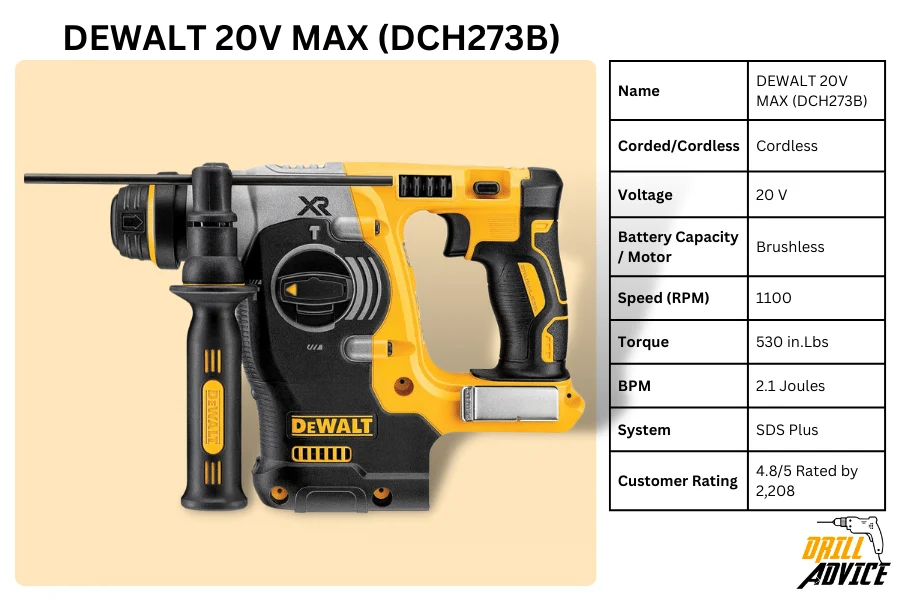

DEWALT 20V MAX (DCH273B)

| Name | DEWALT 20V MAX (DCH273B) |

| Corded/Cordless | Cordless |

| Voltage | 20 V |

| Battery Capacity/ Motor | Brushless |

| Speed (RPM) | 1100 |

| Torque | 530 in.Lbs |

| BPM | 2.1 Joules |

| System | SDS Plus |

| Customer Rating | 4.8/5 Rated by 2,208 |

DEWALT 20V MAX (DCH273B) is an SDS rotary hammer drill powered by batteries. You can use it for drill, hammer drilling, and chipping. Its short design and cordless power can provide an extreme outdoor user experience. You can drill 92 holes per charger using a DCB205 battery. SDS plus drill bits can be used in the drill and its maximum size is 20mm.

ENEACRO

| Name | ENEACRO |

| Corded/Cordless | Corded |

| Voltage | 120 V |

| Battery Capacity/ Motor | 13 Amp |

| Speed (RPM) | 820 |

| Torque | 5.5 Ft.lbs |

| BPM | 4,200 |

| System | SDS Plus |

| Customer Rating | 4.6/5 Rated by 1,790 |

ENEACRO is an SDS plus hammer drill that can be used for heavy-duty concrete and metalworking project. There are four different functions of drill only (suitable for wood, steel, etc.), hammer only (suitable for concrete or brick), hammer drill (suitable for heavy duty work) function and chisel position adjustment adapt to a variety of work scenarios which are easy to switch. Due to the safety clutch, you can protect the wrist when a hammer is subjected to high torque. Its max concrete drilling diameter is 1 1/4″ and for metal, it is 1/2″.

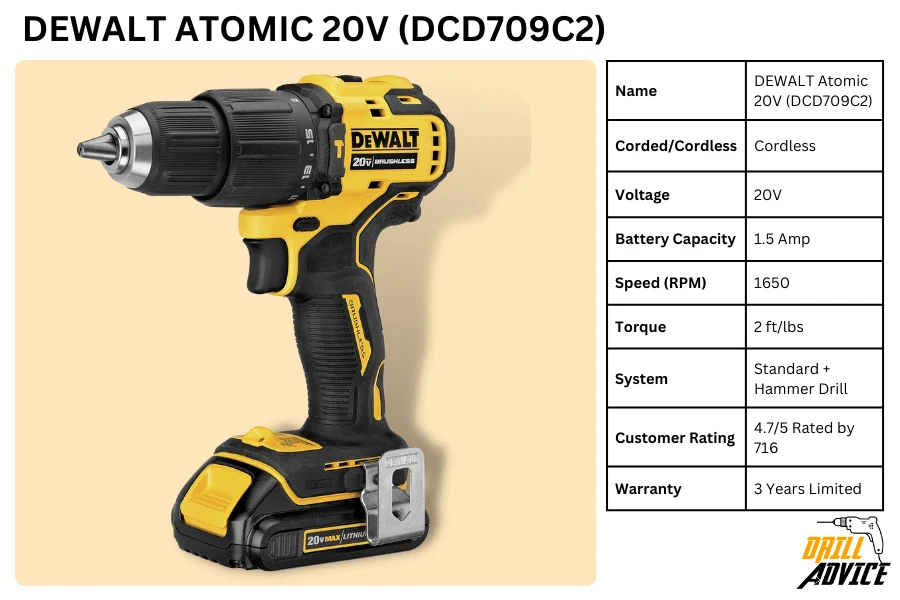

DEWALT ATOMIC 20V (DCD709C2)

| Name | DEWALT Atomic 20V (DCD709C2) |

| Corded/Cordless | Cordless |

| Voltage | 20V |

| Battery Capacity | 1.5 Amp |

| Speed (RPM) | 1650 |

| Torque | 2 ft/lbs |

| Sytem | Standard + Hammer Drill |

| Customer rating | 4.7/5 Rated by 716 |

| Warranty | 3 Year Limited |

DEWALT Atomic 20V (DCD709C2) is a cordless hammer drill with 2 batteries (1.5 Ah). This is one of the best solutions for concrete drilling using battery power. When you buy it you can have 2 batteries, a charger, and a bag. Due to the short length (6.85″), it can operate easily. As well as there is a 2-speed brushless motor that gives minimum maintenance and maximum power use. There is a LED system that provides optimum illumination in dark places. The handle is ergonomically designed for increased comfort, balance, and easier tool control.

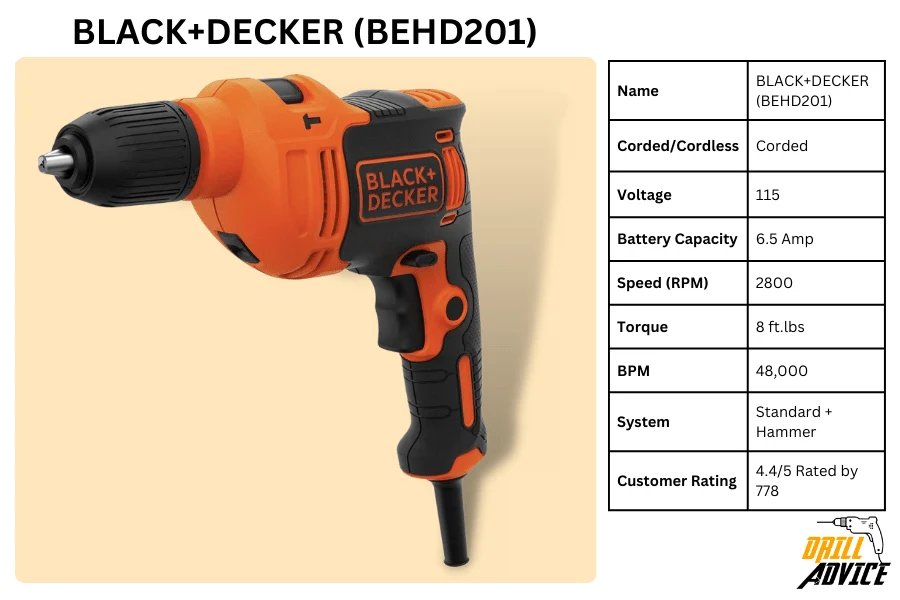

BLACK+DECKER (BEHD201)

| Name | BLACK+DECKER (BEHD201) |

| Corded/Cordless | Corded |

| Voltage | 115 |

| Battery Capacity/ Motor | 6.5 Amp |

| Speed (RPM) | 2800 |

| Torque | 8 ft.lbs |

| BPM | 48,000 |

| System | Standard + Hammer |

| Customer Rating | 4.4/5 Rated by 778 |

Black and Decker (BEHD201) is a corded electric hammer drill that is powered by the 6.5 AMP motor. There is only two function switch for standard drill or hammer drill. Chuck size is 1/2″. You can use this for wood drilling also. A comfortable handle and grip will add more user-friendliness to the user. You are not able to use the chisel here. As well a keyless chuck can change the drill bits easily.

SKIL (HD182001)

| Name | SKIL (HD182001) |

| Corded/Cordless | Corded |

| Voltage | 120 |

| Battery Capacity/ Motor | 7.5 Amp |

| Speed (RPM) | 3000 |

| Torque | 8 ft.lbs |

| BPM | 48,000 |

| System | Standard + Hammer |

| Customer Rating | 4.5/5 Rated by 1,192 |

SKIL (HD182001) is a corded hammer drill with a 1/2″ chuck. Due to the 7.5 Amp motor, you can have higher torque. Due to the two-finger control trigger, you can have comfort and stable spinning control. This is a real tool for drilling both concrete and wood due to the standard and hammer actions. You cant use this for drive screws because its speed is too high. I can recommend this for both wood and concrete drilling purposes.

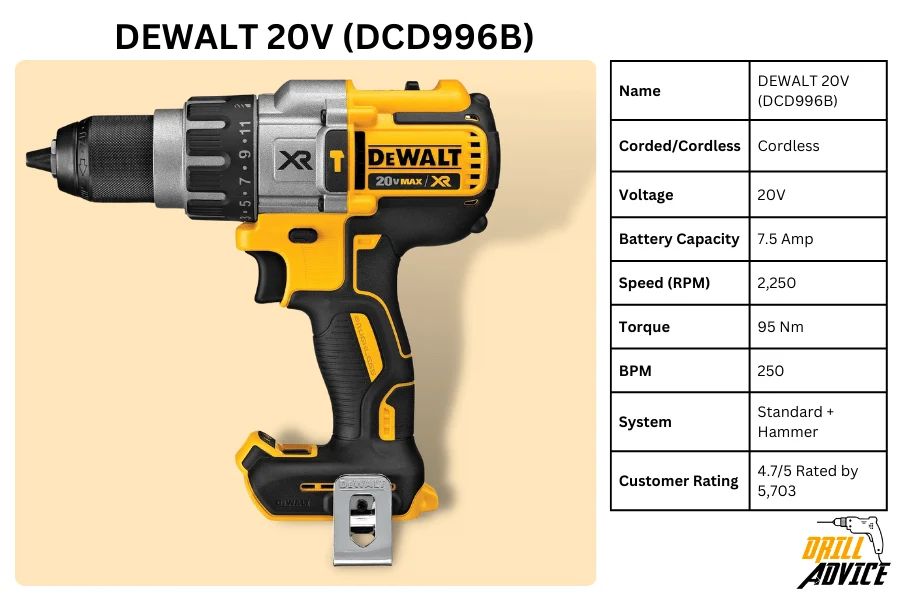

DEWALT 20V (DCD996B)

| Name | DEWALT 20V (DCD996B) |

| Corded/Cordless | Cordless |

| Voltage | 20V |

| Battery Capacity/ Motor | 7.5 Amp |

| Speed (RPM) | 2,250 |

| Torque | 95 Nm |

| BPM | 250 |

| System | Standard + Hammer |

| Customer Rating | 4.7/5 Rated by 5,703 |

DEWALT 20V (DCD996B) is one of the brushless hammer drills with a 3-speed control. Its power source is a battery and you can use a maximum drill bit size of 13mm. Chuck size is 1/2″ and there is a 3 mode LED lights that can be used in dark areas. Due to the brushless motors, you can have 75% of runtime than brushed ones. You cant use this as a chisel.

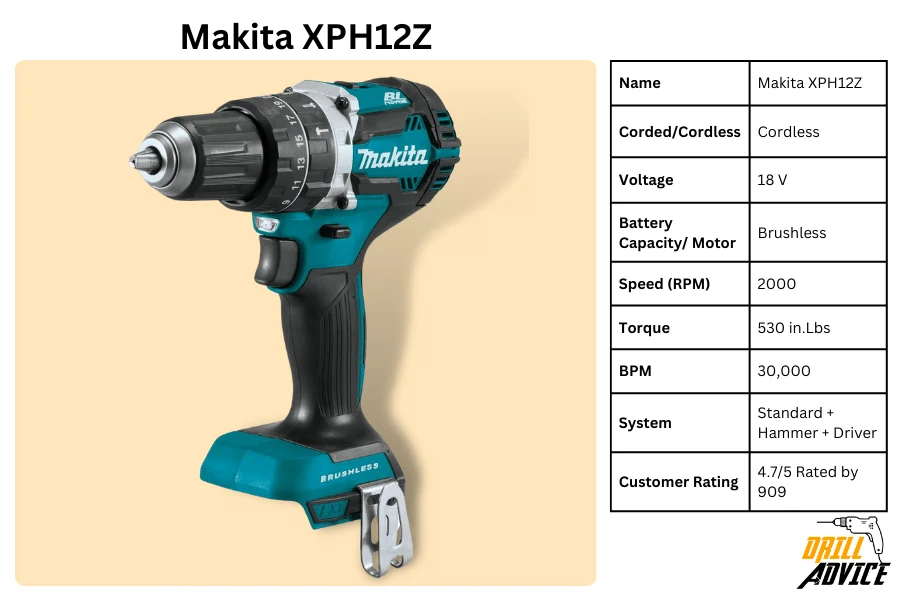

Makita XPH12Z

| Name | Makita XPH12Z |

| Corded/Cordless | Cordless |

| Voltage | 18 V |

| Battery Capacity/ Motor | Brushless |

| Speed (RPM) | 2000 |

| Torque | 530 in.Lbs |

| BPM | 30,000 |

| System | Standard + Hammer + Driver |

| Customer Rating | 4.7/5 Rated by 909 |

Makita XPH12Z is a battery-powered hammer drill with a brushless motor. Its chuck is 1/2 and the lightweight tool can be handled using one hand. You can use this for driving and drilling. So it can be used to fastenings, drilling on wood and concrete also. Its weight is 4.2 pounds with the battery and it is really worth it for drilling mid-size drilling purposes.

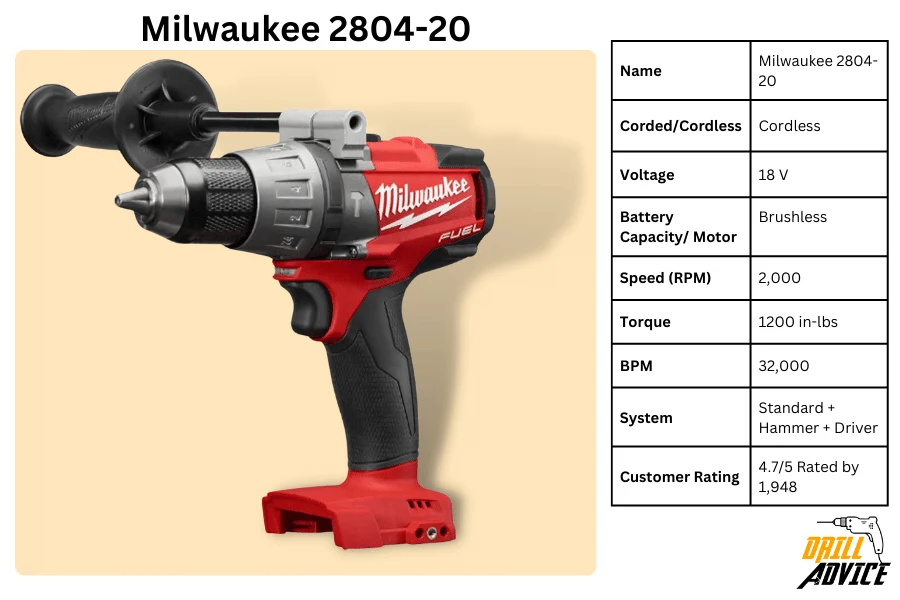

Milwaukee 2804-20

| Name | Milwaukee 2804-20 |

| Corded/Cordless | Cordless |

| Voltage | 18 V |

| Battery Capacity/ Motor | Brushless |

| Speed (RPM) | 2,000 |

| Torque | 1200 in-lbs |

| BPM | 32,000 |

| System | Standard + Hammer + Driver |

| Customer Rating | 4.7/5 Rated by 1,948 |

Milwaukee 2804-20 is a cordless hammer drill with 1200 in-lbs of torque. It is a well-designed hammer drill with Milwaukee M18 series. You can use a Lithium XC 5.0 battery pack which delivers more work over the life of the pack than other brands.