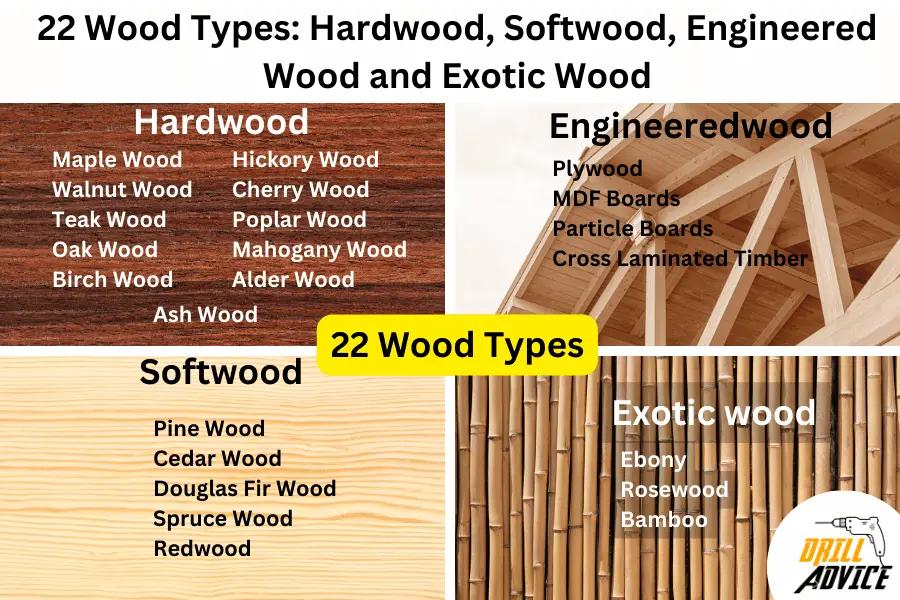

Wood is widely used in woodworking. Wood is mainly used for furniture making and house construction. The usage of the wood depends on the properties of the wood. Wood has properties such as structure, strength, density, specific gravity, knots, grain pattern, colour and growth rings. According to the types of wood, these properties are varied. Woods are mainly 4 types. Those are hardwood, softwood, engineered wood and exotic wood.

Hardwood has higher strength, stability, density, and lower workability. Hardwood has higher compression strength and tensile strength. The hardwood density is higher and tough. Due to its high density and strength, hardwood is durable, tough, high insect resistant, and has a lower workability. Therefore power tools need to sharpen and maintain regularly while working with hardwood. The most used hardwood are Maple, Walnut, Teak, Oak, Birch, Hickory, Cherry, Poplar, Mahogany, Alder, and Ash.

Softwood comes from coniferous trees. Softwood are lightweight and less strength, lower dense than hardwood. Therefore softwood is less durable and has higher workability. As a result of higher workability, softwood can be cut, sawed and drilled easily. The most used softwoods are Pine, Cedar, Douglas Fir, Spruce, and Redwood.

Engineered woods are man-made woods. Engineered wood is made using the particles, dust, chips and lumbers of the wood with a binding agent. The strength of the engineered wood is varied with the wood, wood particle and binding agent. Engineered wood has a well-finished surface and constant cross-section and strength. But engineered wood can fail due to water and wetness. Therefore engineered wood is used for indoor projects. The most used engineered woods are Plywood, MDF boards, Particle boards and Cross-laminated timber.

Exotic woods are considered as woods which are outside the USAExotic woods have special properties such as smell, higher density, and attractive colour. Therefore most exotic woods are not allowed for commercial usage. Therefore exotic woods are mostly used for crafts. Some exotic woods are banned in these countries and need special permission to use them. These kinds of rules and regulations will protect these valuable trees.

Hardwood

Hardwood is considered as wood from dicot trees. Hardwoods are easily identified by their annual leaves losing. Hardwood has higher strength, stability, and lower workability. Hardwood has a dense and strong heartwood. Therefore hardwood is used for a wide range of uses, such as furniture, musical instruments, and flooring.

The wood hardness is measured using the Janka test, which quantifies the force needed to embed a small steel ball halfway into the wood. Hardwoods typically score high on this scale, indicating their resistance to dents and wear. The hardest commercially available wood is Australian Buloke.

Working with hardwood needs powerful power tools and sharp and strong cutting edges. Hardwood is more durable and insect resistance. There is less water absorption ability. These features make hardwoods ideal for high-traffic applications like flooring and furniture.

Hardwood’s texture and color vary significantly depending on the species. For instance, oak has a prominent grain and a warm, golden hue, while maple is more subtle, with a lighter, cooler tone. There are types of hardwoods available in the USA.

Only Know about wood type like hardwood, you can’t start a woodworking project. You should know about wood properties, damages, and protections for a successful woodworking project.

These are 11 most used hardwoods in the USA.

Maple Wood

The maple tree is scientifically named Acer. It is, is a type of hardwood which is originating from the Northeastern regions of North America. The average height of the maple tree is 50-60 feet, with an average diameter of 1- 3 feet.

Maple has higher strength and stability. Hard maple or sugar maple is the hardest maple with 1450 Janka values. It is stronger than softwood and many hardwoods. It is durable and stable due to its high-density heartwood.

The workability of Maple is difficult due to its hardness. But it is possible to cut with the right power tools. Its drilling and cutting capability requires more power compared to softer wood types.

The durability of Maple is ultra-durable with good maintenance; it can last for decades. Its resilience makes it a worthwhile investment for long-lasting woodwork projects.

The texture of Maple is generally fine, and the colour ranges from light to medium tones, usually cream to light reddish-brown. The light colour palette of Maple provides an excellent canvas for staining and finishing, affecting the final look of products beautifully.

Maple is mainly used in furniture making, flooring, and cabinetry, due to its strength, stability, and workability. Its attractive colour, texture, and robustness make it a preferred choice amongst woodworkers and DIY enthusiasts.

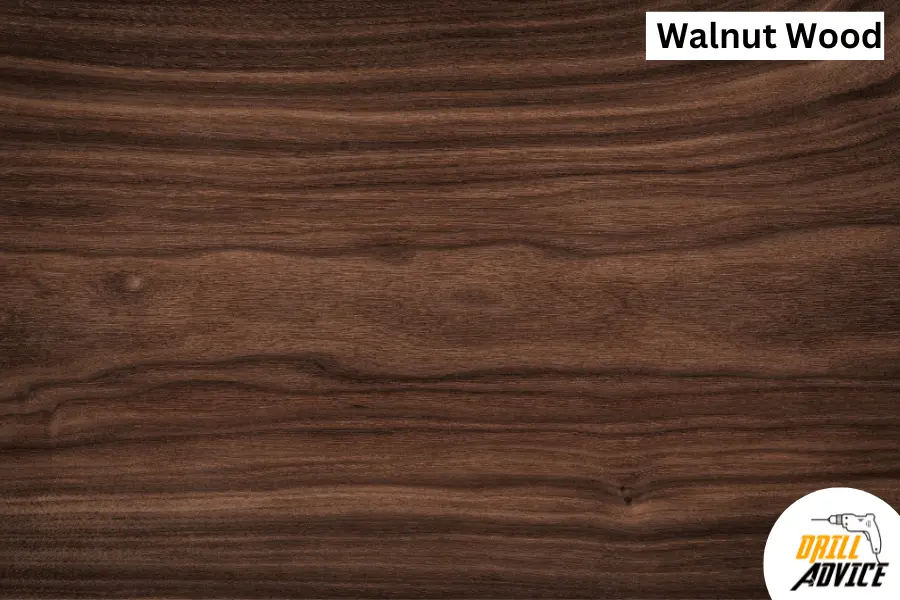

Walnut Wood

The walnut tree is scientifically named as Juglans. This is a hardwood, and it originates from Eastern Europe through to Southwestern China, with trees reaching heights between 70-100 feet and diameters varying between 2-4 feet.

It has great compression and tensile strength than many woods, for example, Pine and Cedar. This solid structure and its high degree of stability make Walnuts highly suitable for woodworking.

Walnut’s workability is excellent. With power tools, drilling and cutting this wood is more straightforward compared to tougher hardwoods like Oak. Walnut’s durability, too, is impressive. Properly maintained, it can last for several decades, demonstrating its exceptional long-term value.

Walnut has a rich, dark colour and straight grain. Therefore Walnut’s texture is coarse but finishes well. The deep chocolate brown tone of Walnut enhances the beauty of the finished products, giving them an elegant, timeless appeal.

Walnut’s primary usage is in the creation of furniture and veneer. Its superior strength, stability, workability, and stunning aesthetics make it a favorite choice for many woodworkers and DIY enthusiasts.

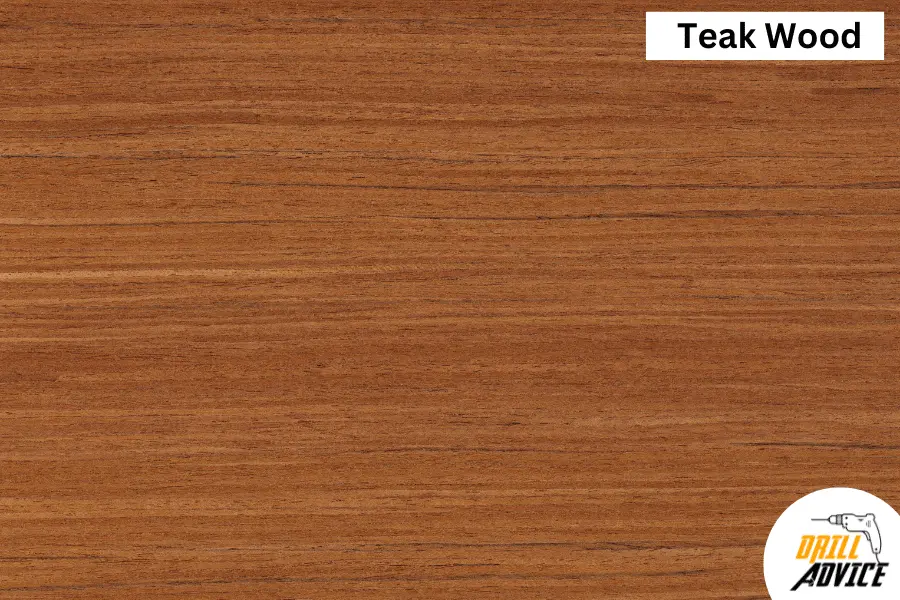

Teak Wood

The teak tree is scientifically known as Tectona grandis. Teak originates from South and Southeast Asia; this hardwood grows up to 150 feet (46 meters) tall with and diameter up to 5 feet. Teak is stronger and more stable than many wood types. Teak surpasses the likes of Pine and Cedar in compression and tensile strength.

Teak provides moderate ease of drilling and cutting workability. Due to the dense heartwood, teak can last over 70 years.

Teak presents a straight grain and coarse texture. The colour ranges from yellow-brown to dark golden-brown, becoming even richer as it ages, ultimately affecting the stunning aesthetics of finished products.

Teak is primarily used for high-end furniture, decking, and boat building, due to its strength, stability, and workability. With these qualities, teak is an important wood in woodworking.

Oak Wood

Oak is scientifically known as Quercus. Oak originates from the temperate and tropical regions of the Northern Hemisphere. This hardwood tree can grow up to a height of 70 feet with a diameter of 9 feet.

Oak has a tensile strength of 11,200 psi, and a compression strength of 7,440 psi. Therefore it outperforms many softwoods and hardwoods.

Oak has moderate easy workability. Oak’s density and strength can make drilling and cutting more difficult, but it can be done easily with using proper sharpened power tools.

Oak wood has more than 100 years of durability. This surpasses many other wood types in longevity, making it an exceptional choice for durable applications.

Oak wood is characterized by its rich, warm colour and straight-grain texture. Its beautiful reddish-brown hue tends to darken over time, enhancing the aesthetic appeal of finished products.

Birch Wood

The scientific name of the Birch tree is Betula. It originated from the Northern Hemisphere, predominantly in North America and Europe. It’s a hardwood, and fully grown trees can reach up to 70 feet in height and up to 2 feet in diameter.

The average compression strength of birch is 8170 psi, and its tensile strength is 14,500 psi (100 MPa). The stability of Birch is quite high, indicating that it resists swelling and shrinkage well.

The workability of birch is generally high. It has a smooth surface that’s relatively easy to drill and cut compared to harder wood types. However, sharp tools are recommended to maintain precision due to its density.

Birch is quite durable and, with proper care, can last for many decades. Its resistance to decay is more significant than many other types of wood, although it’s not impervious to insect attack.

The texture of birch wood is generally fine and uniform, featuring a straight grain. Its colour ranges from a light yellow to a creamy white, a feature that can significantly impact the appearance of finished products.

Hickory Wood

Hickory is scientifically named as Carya. It is a type of hardwood that originates from North America. Mature trees can reach heights of 40 m (130 ft) with a diameter of 122 cm (48 in)

In the strength and stability department, hickory stands out. Boasting a compression strength of approximately 7,580 psi and a tensile strength of around 20,000 psi, it surpasses most other hardwoods. Its stability is solid, and known for having minimal reaction to environmental changes.

Regarding workability, hickory is difficult due to its exceptional hardness. Drilling and cutting require sharper tools compared to softer woods.

In terms of durability, hickory has a lifespan that can extend well beyond 120 years, and there is a natural resistance to decay that outpaces many other wood types.

The texture of hickory wood is somewhat coarse but uniform, with a straight grain. Its colour palette varies from lighter sapwood to darker heartwood, influencing the aesthetic of finished products.

Cherry Wood

Cherry is a hardwood. It is scientifically known as Prunus Serotina. Cherry is native to North America. Cherry trees can mature to heights of 40-50 feet, with a trunk diameter reaching up to 2 feet.

Cherry has a medium strength among hardwood. It has a compressive strength of about 7,110 psi and tensile strength of roughly 12,300 psi. It’s not as tough as Hickory or Oak but offers more stability, with reduced shrinking and swelling properties.

The workability of cherry is ease in cutting and drilling, offering an excellent surface for power tools compared to harder woods, making it an excellent choice for both beginners and experienced woodworkers.

When it comes to durability, Cherry holds its own. Under the right conditions, this wood can last over a hundred years, particularly when used indoors, where it’s less exposed to elements.

Cherry wood is appreciated for its smooth, straight-grained texture and vibrant colour that deepens from a rich red to a reddish-brown as it ages. This natural progression of colour significantly contributes to the aesthetic value of finished products.

Poplar Wood

The scientific name of the popar is Populus. It originates from the Northern Hemisphere. It’s considered as a hardwood, despite its softer properties. Poplar trees grow rapidly, reaching heights of 50-165 feet (15-50 meters), and diameters up to 8 feet.

In terms of strength, Poplar is known more for its stability than its outright strength. With compressive strength averaging around 5,400 psi and tensile strength around 10,100 psi, it isn’t as robust as Oak or Hickory. But it scores high in stability due to its resistance to warping and twisting.

Poplar’s workability is its key strength, often regarded as one of the most machinable hardwoods. Whether you’re drilling or cutting, Poplar’s soft nature and minimal grain pattern make it an ideal choice for beginners, compared to harder wood types.

Poplar lifespan often ranges from 20-50 years, which is lower than that of woods like Cherry or Oak.

The texture of Poplar is fairly uniform, with a fine grain and a creamy white to yellowish colour. While not as striking as other woods, it takes paint and stains well, making it versatile for finished products.

Mahogany Wood

The Mahogany tree, scientifically known as Swietenia Mahagoni, is a hardwood originating from the tropical rainforests of South and Central America. It can grow up to 75 feet tall and have a diameter of 3-6 feet.

Mahogany is appreciated for its strength and stability. With a tensile strength of about 11,500 psi and compressive strength of 7,500 psi, Mahogany demonstrates moderate strength. It is stronger than Pine and Poplar but lesser than Oak and Hickory. Mahogany has excellent stability. Therefore it is resistant to warping or twisting.

The workability of the mahogany is better than the denser wood like Hickory or Maple.

Durability is one of the reasons Mahogany is so prized. Well-maintained Mahogany can last several hundred years.

Mahogany’s texture is fine to medium with an attractive straight, rippled or interlocked grain. Its colour ranges from a soft pinkish-brown to a deep red-brown, adding a warm richness to the finished product.

Alder Wood

Alder, known scientifically as Alnus, is a hardwood native to the temperate zones of North America, Europe, and Asia. It matures at a moderate height of around 70 to 120 ft in height (130 ft maximum) and 10 to 34 in. in diameter (70 in. maximum)

Alder has considerable strength and stability. Alder has a tensile strength of 9,800 psi and compressive strength of 5,920 psi; Alder stands superior to Pine but less strong than Oak. Its stability is remarkable, offering excellent resistance to warping and shrinkage.

Alder is distinguished by its outstanding workability. Its moderately soft, straight-grained structure is easy to cut and drill, making it more workable than denser hardwoods like Hickory or Maple.

The durability of Alder is respectable, often lasting around 60 years when properly maintained, which is more than Pine but less than most other hardwoods.

Alder wood has a fine, uniform texture with an even grain. The colour varies from pale yellow to reddish-brown, affecting the aesthetic appearance of finished products by providing a warm, inviting look.

Ash Wood

The Ash tree, scientifically known as Fraxinus. It is a hardwood and native to North America, Europe, and Asia. Typically, an Ash tree reaches up to 70-90 feet in height with a 2-3 feet diameter.

The tensile strength of ash wood is 12,400 psi, and a compressive strength of 7,410 psi, Ash ranks higher than Alder but not as high as Oak. Stability-wise, Ash standout with significant resistance to warping and shrinking.

Ashwood is known for its high workability. It offers superb machinability for power tools due to its straight grain, making it more workable than many hardwoods, such as Walnut or Cherry.

When maintained correctly, Ash can last approximately 70 years, showing better durability than Alder but falling short of Teak or Ipe.

Ash exhibits a moderately coarse, uniform texture and a straight grain. Its colour ranges from light to medium brown, offering a natural, earthy feel to finished products.

Softwood

Softwood, are comes from evergreen or coniferous tress such as pine or fir. The hardness of softwood is assessed with the Janka test, as it is for hardwood. However, most softwoods have lower Janka ratings, indicating they’re easier to cut or shape.

Softwood has higher workability than hardwood. Therefore it is easy to use hand or power tools. Woodworkers appreciate this characteristic, especially for projects requiring intricate carving or precise cuts.

In terms of durability, softwoods generally don’t match the longevity of hardwoods. However, certain types, such as cedar, have natural resistances to decay and pests. This will increase the cedar’s lifespan.

Softwoods display a range of textures and colors. Pine, for example, has a light color with a smooth texture, while cedar can exhibit a reddish hue with a slightly rough texture.

The softest known wood is Balsa. Many softwoods are available in the USA. These are the 5 most used softwoods in the USA.

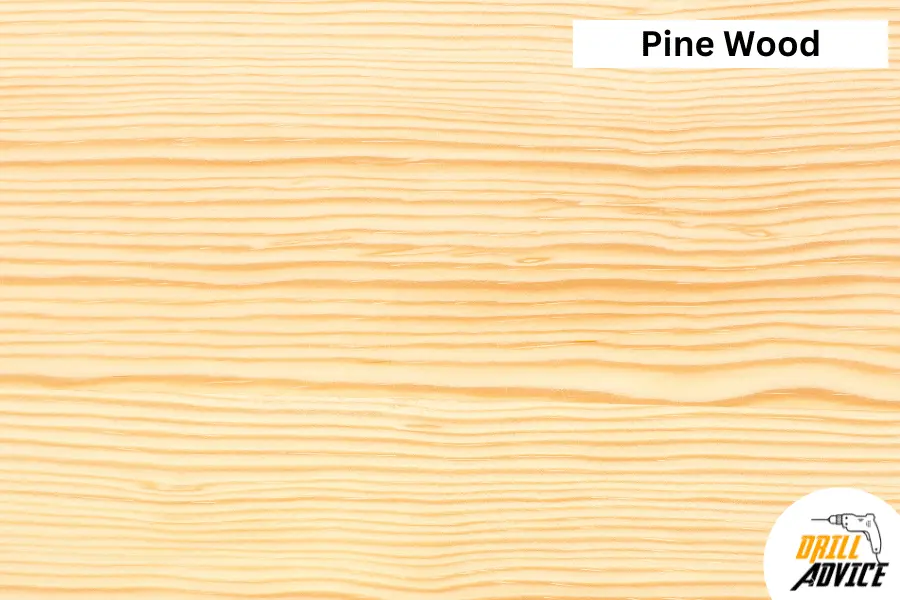

Pine Wood

The Pine tree, scientifically known as Pinus. Pine is native to the Northern Hemisphere. A softwood species, its height ranges from 50-150 feet (15-45 meters) with a 1-2.5 feet diameter.

In terms of strength and stability, Pine has moderate strength compared to hardwoods like Oak. With a compressive strength of around 5,000 psi and tensile strength of approximately 8,800 psi, it exceeds the strength of Cedar. Its stability is generally good, offering solid performance across diverse applications.

Pine’s workability is excellent due to its softness, surpassing many hardwoods. The cutting and drilling process of Pinewood with power tools is smooth and easy, unlike some tougher hardwoods like Walnut.

The durability of Pinewood is around 10 to 15 years, less durable than most hardwoods but generally like other softwoods.

Pinewood presents a pale yellow colour with a straight grain, and its texture varies from fine to coarse. The colour plays a significant role in the final aesthetic appeal of products made from Pine.

Cedar Wood

The Cedar tree, scientifically known as Cedrus, originates predominantly from the mountainous regions of the Mediterranean and the Himalayas. This softwood can grow up to 100′-150′ (30-46 m) and spread diameter of 15′-30′ (4.6-9.1 m).

Cedar has a compression strength of about 4,200 psi and tensile strength reaching up to 7,500 psi. It is relatively strong compared to many softwoods, although inferior to hardwoods like Maple. Stability is one of Cedar’s virtues, offering consistency in various climatic conditions.

Its workability is among the best in wood types. Cutting and drilling Cedar with power tools is a straightforward task, usually more comfortable than working with hardwoods such as Oak.

In terms of durability, Cedar impresses with an approximate lifespan of 20 to 25 years, outliving most softwoods yet trailing behind several hardwoods.

Cedar has a clear reddish-brown colour with a straight grain and medium to coarse texture. Its colour significantly impacts the aesthetic value of the finished products, giving a warm, rustic charm.

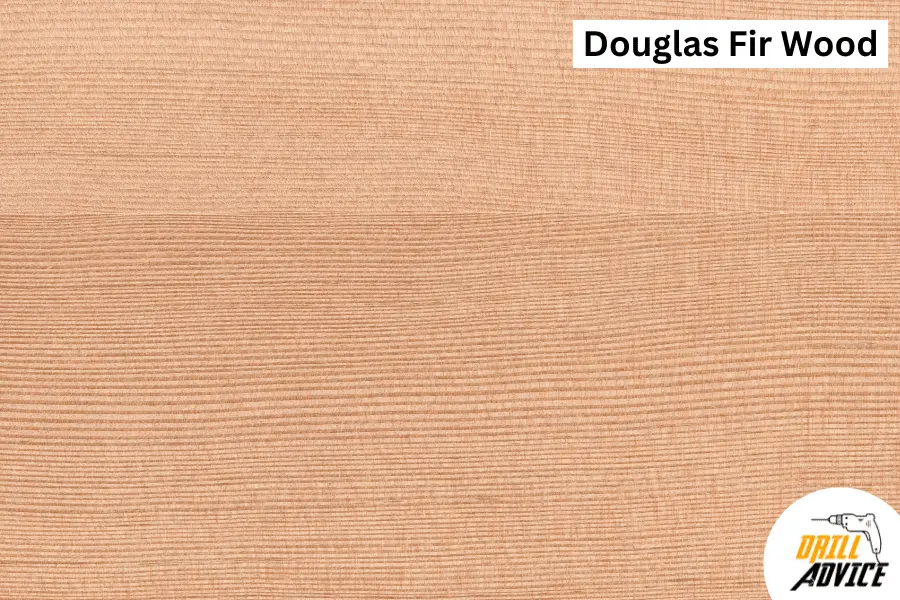

Douglas Fir Wood

Douglas fir, known scientifically as Pseudotsuga menziesii, originated from North America. This softwood can reach heights of 250-300 feet with diameters between 5-7 feet.

In terms of strength, Douglas fir has a compression strength of about 7,230 psi and tensile strength around 12,400 psi, making it one of the strongest softwoods.Its stability is highly praised, holding its shape under varying conditions.

Its workability is acceptable, not as easy as Cedar, but with proper power tools, Douglas fir can be cut and drilled with relative ease.

Douglas fir impresses with its durability, often enduring 50 to 75 years, surpassing many softwoods and even some hardwoods.

Its texture is typically straight-grained with a medium to coarse feel. The colour varies from yellowish-brown in the sapwood to reddish-brown in the heartwood. This vibrant hue positively influences the aesthetic appeal of finished products.

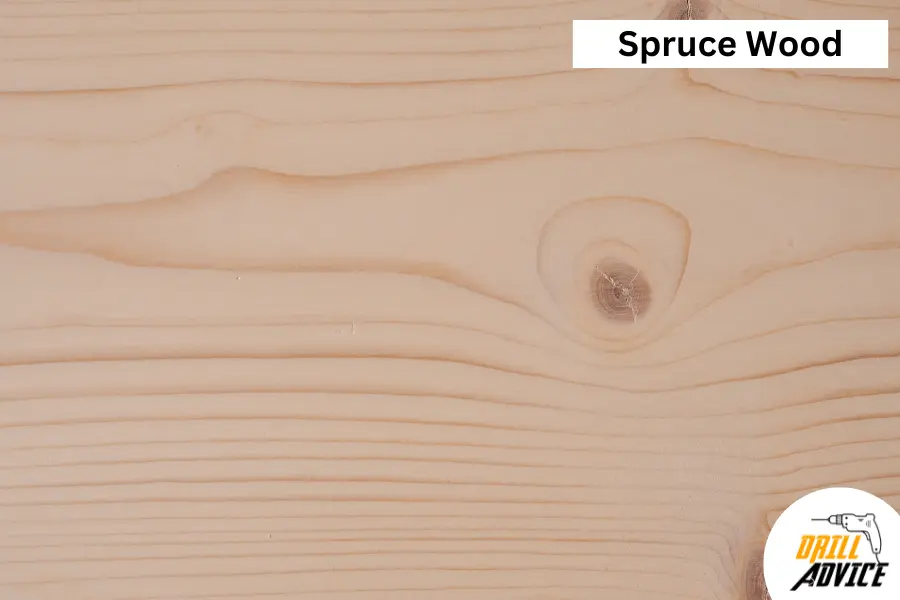

Spruce Wood

The spruce tree is scientifically named Picea. It is a native softwood from the Northern Hemisphere. These trees’ height can be 60-90 feet tall and 2 feet wide of the trunk.

In terms of strength, Spruce’s tensile strength outshines many other softwoods, making it resilient to various forces. Spruce’s stability contributes to its popularity in the construction and manufacturing industries.

Spruce’s workability is noteworthy. It is known for its versatility with power tools, including cutting and drilling, outmatching other hardwoods in this respect.

When we turn to durability, spruce wood holds its own, standing firm for decades when properly treated and maintained.

The texture of spruce is fine and consistent, with a light, almost white colour. The light tone gives the wood a certain adaptability, allowing it to be stained or painted according to preference, affecting the finished products’ aesthetics.

Redwood

Redwood trees, scientifically known as Sequoia sempervirens. It is originated from the coastal regions of Northern California. It is a softwood. The average mature trees towering height is 200-240 feet, and the diameter of 10-15 feet.

When it comes to strength, Redwood is moderately strong compared to hardwoods but exceeds many softwoods in both compressive and tensile strength. It has excellent stability, resisting warping or splitting over time.

In terms of workability, Redwood shines with power tools. Cutting and drilling pose minimal challenges when compared to harder woods, making it a favored choice for woodworking and DIY projects.

Durability-wise, Redwood is known to last for decades, surpassing most other wood types. This longevity adds to its appeal.

The Redwood’s texture is moderately coarse but uniform. The colour ranges from a light cherry-red to a dark reddish-brown, and this colour can significantly impact the aesthetic of final products, offering a warm, rich hue that’s often sought after.

Types of Engineered Wood

Engineered woods are man-made wood. Engineered wood is a high-performing composite product, which has been designed to maximize the natural strength and stiffness of wood. It is a useful material for projects that require stable, durable, and consistent quality.

Engineered woods are used in a variety of construction applications due to its stability and strength. Engineered wood are mostly used for floors, beams, and walls. These woods are available as sheets. Mainly engineered woods are 4 types those plywood, MDF board, particle board and cross-limiting timbers.

Hardness in engineered wood varies with the type of wood fibers used. Predominantly, it has a high degree of hardness and is available in various sizes, improving its versatility.

The workability of engineered wood is excellent. Woodworkers often find it easier to cut and shape than solid wood, especially when using power tools. It’s less likely to warp or twist, reducing waste and increasing efficiency.

Engineered wood has a higher durability. But it is less prone to splitting and warping due to changes in temperature or humidity, making it a reliable option for long-lasting structures.

Finally, the texture and colour of engineered wood can range from very smooth and uniform to more natural-looking finishes that imitate the look of solid wood. This aesthetic flexibility makes it suitable for various projects, meeting both practical and visual demands.

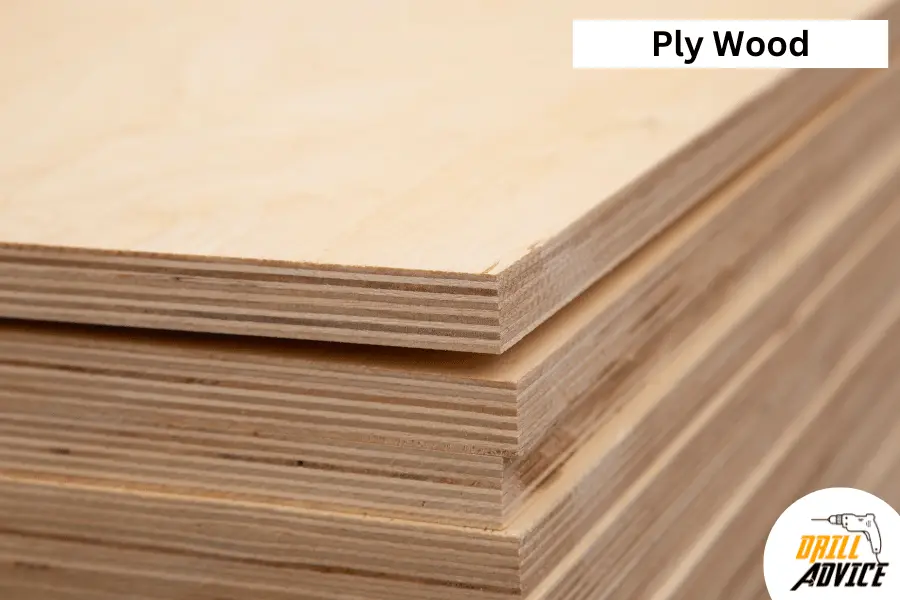

Plywood

Plywood a versatile engineered wood. It is created by gluing thin layers, or ‘plies’ of wood veneer. The adjoining layers are oriented with their grain directions at right angles by improving strength and reducing shrinkage.

Plywood are available as sheets. These sheets are different in size and thickness. The plywood sheets have sizes of 4’ x 8’ and 5’ x 5’. The available thicknesses are 6mm (1/4″), 9.5mm (3/8″), 12.5mm (1/2″), 15.5mm (5/8″), 19mm (3/4″), and 25.5mm (1″)

The tensile strength of the plywood is 4000-5000 psi. In practically A 12-inch by 36-inch sheet of plywood that is 1/4 inches thick will only support 5 pounds per square meter. As well as 12 inches by 36-inch sheet of plywood that is 3/4 inches thick will support 50 pounds per square meter.

This engineered wood finds optimal use in a variety of applications. From construction – in flooring and roofing – to furniture and cabinetry, plywood’s workability makes it a favorite among woodworkers and DIY enthusiasts.

The purpose of plywood extends beyond mere utility. It provides an economical, high-strength solution to woodworking projects while allowing for a high degree of customization. Moreover, it reduces wastage compared to using solid wood.

However, plywood has drawbacks. When its edges are exposed, it reveals the layered structure. The lower-quality plywood can be prone to warping over time and is less resistant to water damage. Despite these cons, the pros of versatility, strength, and cost-effectiveness make plywood an essential engineered wood in woodworking.

MDF Boards

Medium Density Fiberboard (MDF) is a popular type of engineered wood. MDF boards are created from residual hardwood or softwood fibers. The fibers are combined with wax and resin binder, heated and pressed to form panels.

Regarding strength, MDF boards provide a balanced, dense structure, but they aren’t as robust as solid wood or plywood. The standard length and width of MDF boards are 2400mm x 1200mm and 2400mm x 1800mm . It has verities of thicknesses, such as 3mm, 4.75mm, 6mm, 9mm, 12mm, 16mm, 18mm, 25mm, and 32mm.

MDF’s smooth surface makes it suitable for intricate, detailed designs, often used in cabinetry, furniture, and moulding. The primary purpose of MDF lies in its affordability and adaptability, offering a cost-effective alternative to solid wood.

However, MDF has its share of pros and cons. The pros are its smooth finish accepts paint well, and it’s easy to cut, with less risk of splintering. As cons, MDF is relatively heavy, can sag over time under heavy load, and doesn’t handle moisture well. Despite this, for interior applications where strength isn’t the primary concern, MDF remains a reliable, economical choice among engineered wood types.

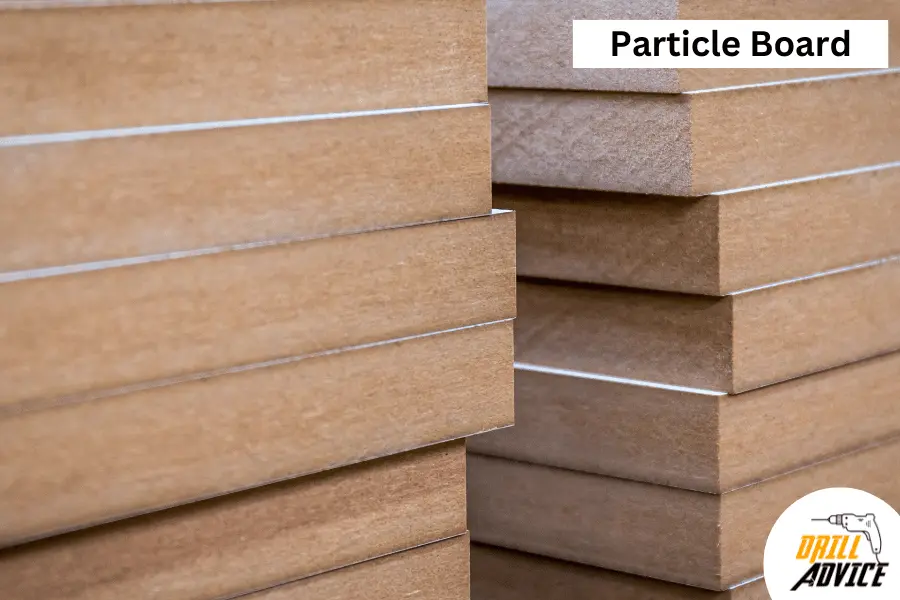

Particle Boards

Particle boards are considered as engineered wood. Particle boards are formed from wood chips, sawmill shavings, or even sawdust glued together under heat and pressure. It’s essentially a recycling of wood leftovers, creating an economical material.

When it comes to strength, particle boards don’t quite match up to solid wood or other engineered types like plywood. The available particle board sizes are 4′ x 8′, 10′, 12′, 5′ x 8′, 9′, 10′, 12′ and Available Thicknesses are 1/4”, 3/8”, 1/2”, 5/8”, 11/16”, 3/4”, 7/8”, 15/16”, 1”, 1-1/8”, 1-1/4”, 1-1/2”

Particle boards are used for variety of interior applications; particle boards are commonly used in low-load situations like cabinet carcasses, shelving, or paneling. They’re purposed for cost-effectiveness, with an impressive ability to hold screws and fasteners well due to their density.

As for pros and cons, particle boards are lightweight, affordable, and good for the environment due to wood waste recycling. However, they don’t handle moisture well, may sag even under small loads, and aren’t suitable for outdoor use. Despite these limitations, particle boards remain a practical choice for specific interior applications where high strength is only one of the priorities.

Cross Laminated Timber

Cross Laminated Timber (CLT), is a type of engineered wood. It is created by layering three to seven sections of lumber orthogonally (odd layers only). This meticulous process enhances stability and strength, as well as dimensional accuracy.

CLT is a stronger material and it can be used for handling heavy loads in construction. The standard CLT dimensions typically range from 2 to 10 inches in thickness and up to 18 feet in width.

CLT’s suitability stretches to a variety of applications. It is perfect for floor, roof, and wall systems, significantly used in large-scale construction projects. Its purpose is to provide a lightweight yet incredibly strong and quick-to-install building material.

The pros of CLT include its high strength, sustainability, and the speed of construction it allows. However, it has its cons, primarily its cost compared to other engineered woods and its need for protective measures against fire and moisture.

Types of Exotic Woods

Exotic woods are considered woods which is outside the USA. Most exotic woods are valuable, and some are not considered as trees. They are plants. Due to the rapid growth and wide availability, those are considered as wood. As an example, bamboo. Most of the exotic woods are used for arts and crafts. Some exotic woods, such as rosewood and ebony, are not able to sell commercially. There are some laws and rules to protect these valuable trees.

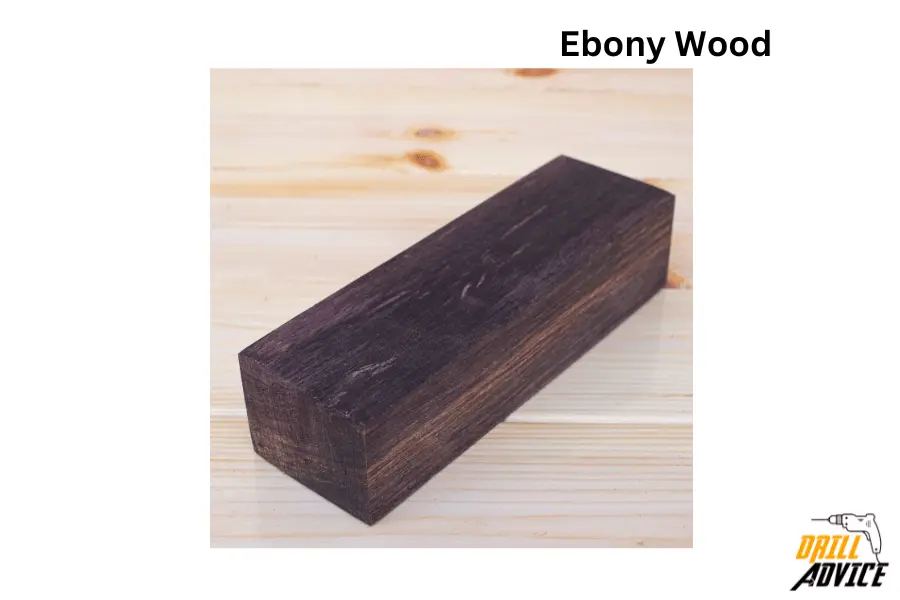

Ebony

Ebony, a distinguished type of hardwood, is famed for its deep black color and smooth texture. It has 1.2 specific gravity, and it is one of the denser and hardest woods in the world. There are several types of ebony, including Diospyros crassiflora, Diospyros celebica, and Diospyros lotus, each with unique qualities.

These woods are native to various regions: Diospyros crassiflora commonly known as Gabon ebony, and African ebony is in West Africa. Diospyros celebica commonly named as Black ebony or Makassar ebony is in Southeast Asia. Diospyros lotus named as Ceylon ebony is in Sri Lanka. This geographical diversity contributes to the nuances in ebony’s properties and its global importance.

The significance of ebony rests on its superior strength, stability, and workability. Its high-density grants exceptional durability, making it ideal for carving intricate details and for use in crafting musical instruments, particularly piano keys and guitar fretboards.

However, the legality of selling ebony varies. Due to over-harvesting, some types, like Diospyros crassiflora, are listed in CITES Appendix II, controlling their international trade to prevent exploitation. Consequently, the use of ebony calls for ethical sourcing and responsible consumption to ensure the survival of these magnificent trees.

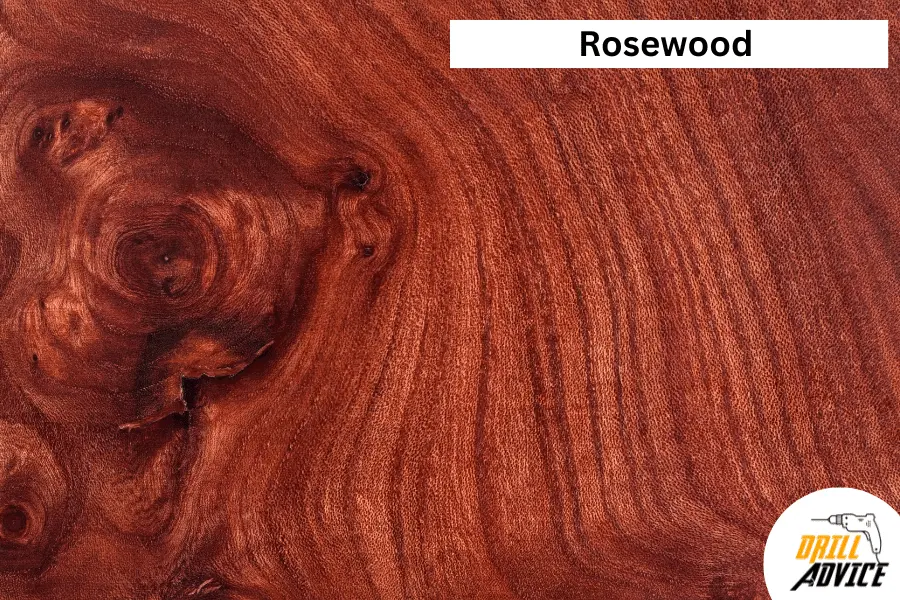

Rosewood

Rosewood is a luxurious hardwood. It is renowned for its rich colour palette and distinctive fragrance. Several types exist, with the most notable being Dalbergia nigra (Brazilian rosewood), Dalbergia latifolia (Indian rosewood), and Dalbergia cochinchinensis (Thai rosewood).

These variations originate from different global regions. Brazilian rosewood is indigenous to Brazil’s Atlantic rainforest, Indian rosewood thrives in the dry deciduous forests of South Asia, and Thai rosewood is native to the monsoon forests of Southeast Asia.

Rosewood is invaluable for its impeccable strength, stability, and workability. The wood’s unique tonal properties make it a preferred choice for making musical instruments such as guitars and violins. Its beautiful grain is also highly sought after for luxury furniture and intricate carvings.

However, due to overharvesting, the legality of selling rosewood is a complex issue. For instance, Brazilian rosewood falls under CITES Appendix I, meaning its trade is highly regulated to prevent species endangerment.

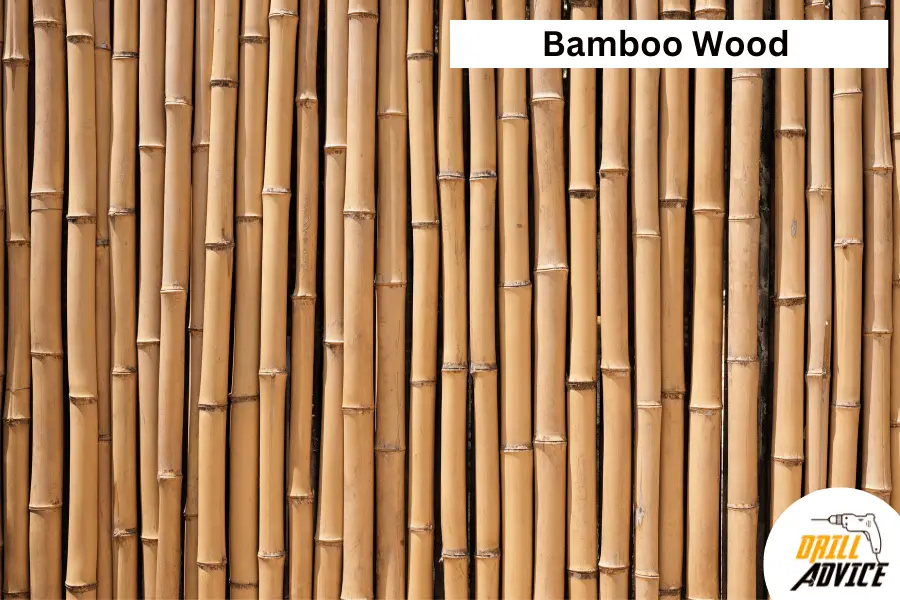

Bamboo

Bamboo is technically a grass but often classified as a wood due to its wood qualities. It consists of several types, the most notable being Moso, Madake, and Henon bamboo.

These varieties are primarily native to East Asia, with China hosting the majority of the world’s bamboo forests. However, bamboo can be found in diverse climates across the globe, including Africa and South America.

Bamboo has rapid growth. Therefore it is a sustainable resource, providing a durable, renewable alternative to hardwood. Additionally, the strength and stability of bamboo rival that of many traditional woods, making it a highly workable material for DIYs and professional woodworkers.

Commonly, bamboo finds use in furniture, flooring, and construction, where its unique aesthetic and structural properties are put to an advantage. Its flexibility also makes it suitable for crafting musical instruments and utensils.

Selling bamboo is perfectly legal, with its cultivation encouraged globally due to its eco-friendly characteristics. However, as with all resources, sustainable and responsible harvesting practices should be adhered to, ensuring the protection of bamboo’s natural habitats.

What are the 10 Types of Engineered Woods?

These are the 10 types of engineered woods.

- Plywood

- Particle Board

- Medium Density Fiberboard (MDF)

- Laminated Veneer Lumber (LVL)

- Glulam

- Cross-Laminated Timber (CLT)

- Hardboard

- I-Joists

- Oriented Strand Board (OSB)

- Fiberboard