When I use my drill for a long period, I could see so many problems arise. Sometimes there is smoking without any load. As well some times it overheats too much. This can arise your self also. So it is important to know about it, and I have mentioned the method to fix it.

A drill is smoking due to an electrical short, old brush with dust, stuck due to heavy load or covering the ventilation. When a drill is overheated, it can be smoke easily. Smoke is the result of spark. It will cost 50$-75$ to repair the drill, and you can do it yourself by replacing brushes.

I could see there is a spark back of my drill. That is another effect that I had to face. All these can be fixed easily. You will need some products to fix this. So let’s keep read on!

What is Drill Smoking?

Drill smoking is emitting smoke from the drill, or drill bit while using. A drill machine smoking are two main types such as drillbit and inside drill smoking.

1. Drill Bit Smoking

Drill-bit smoke rises when there are no lubricants for the drilling process. When there is smoke in drilling, let it cool the drill bit and pour the cutting oil. You can reduce the cutting speed and then restart the process.

2. Drill Inside Smoke

When a drill machine is smoked its inside, it causes main problems such as worn brushes, debris, lack of lubrication, applying too much force on the drill, and use of improper drill machines for heavy-duty tasks. The smell of the drill smoke inside is a kind of plastic melting. Once you notice this, you should stop the drilling let the machine to cool and check for defects.

What are the Reasons for Drill Smoking?

Smoking a drill can happen in two ways. When there is more load, it can be smoke as well as due to the debris it can be smoke. Due to these two reasons, there will be a light smoke with the smell. So let’s consider each one in detail.

There is torque and speed in the drill. When we work, the speed or torque can be exceeded. Some time drills can be stuck due to the more load. At that time, its coils can be heated, and some parts can be heated and melt. Due to this, smoking can arise.

When we are working with the drill, we should not close the ventilation holes. When the ventilation hole is closed, inner air is not able to flow. So inner temperature is increased, and it can be overheated and smoke.

When we use a drill long period, dust and some debris can go inside the drill. When these are mixed with inside oils and grease can dirt the inside. When the motor is rotated, these particles also move with the motor and then spark, and smoking can rise.

What are the Reasons for Drill Overheating?

Overheating a drill has so many reasons. Those reasons are also causing smoking also. Check the below reasons for overheating the drill.

- Apply more pressure

- Covering the ventilation holes

- Insufficient torque

- Electrical short

- Mechanical problem

- Old brushes

- Continous working

- No lubricants

- Wrong drill bit angle

You can check in detail about drill overheating on Why is My Drill Overheating?

How to Fix Drill Smoking?

You can fix the drill smoking by following the steps below.

You will need

- Screwdriver

- Electrical contact cleaner

- Compressed air cleaner

- Needle-nose plier

1. Remove the Power Supply

2. Using a screwdriver, open the drill by removing the fixed screws.

Carefully keep the removed screws. You can use a magnet for that.

3. When you open it, you can see there is a brush.

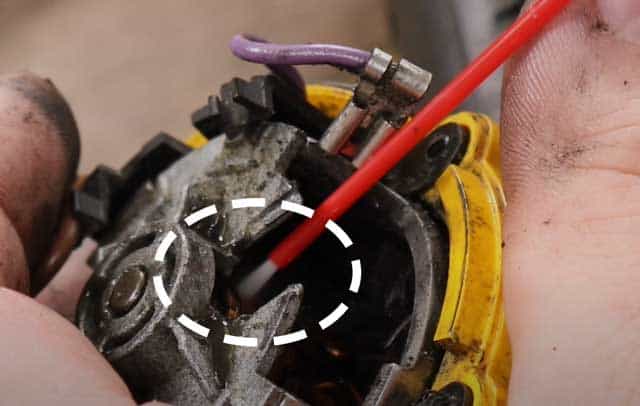

If you can push the trigger, you can see the inner sparks.

4. Remove the brushes using a needle plier and check the condition of the brushes

5. If brushes are not able to reuse, replace carbon brushes.

6. Using compressed air, clean the inside of the motor.

7. Use an electrical contact cleaner to clean the commutator.

If you can remove the inner dirt material such as dust between the commutator copper parts, do it. Those will cause the spark and smoke.